W flame boiler combustion optimizing device

A technology of boiler combustion and optimization device, applied in the field of boiler combustion, can solve the problems of large thermal deviation of W-flame boilers, over-temperature heating load of water-cooling wall, uneven heating load, etc., so as to reduce combustion fluctuation and thermal deviation, reduce harm and impact small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

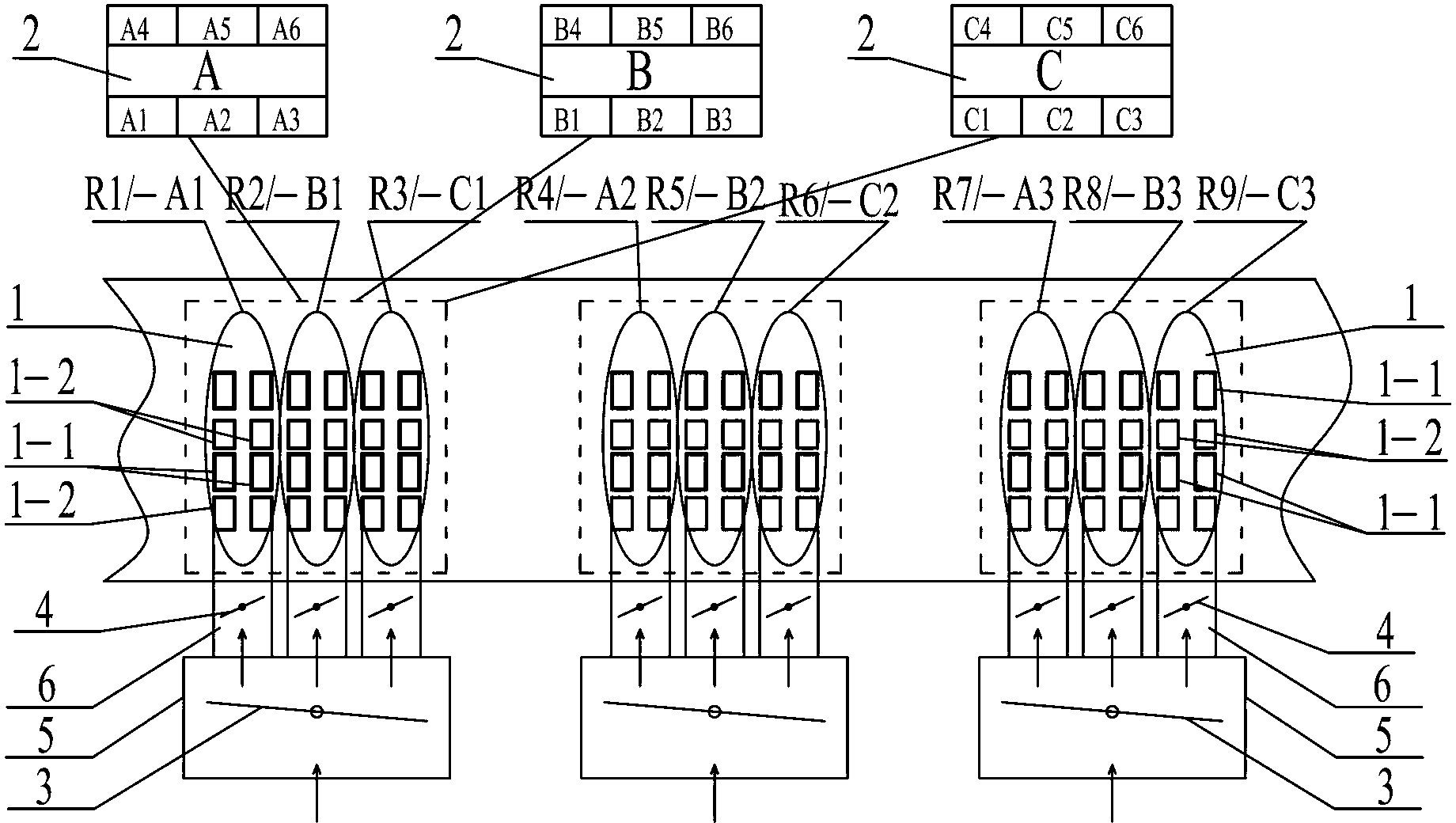

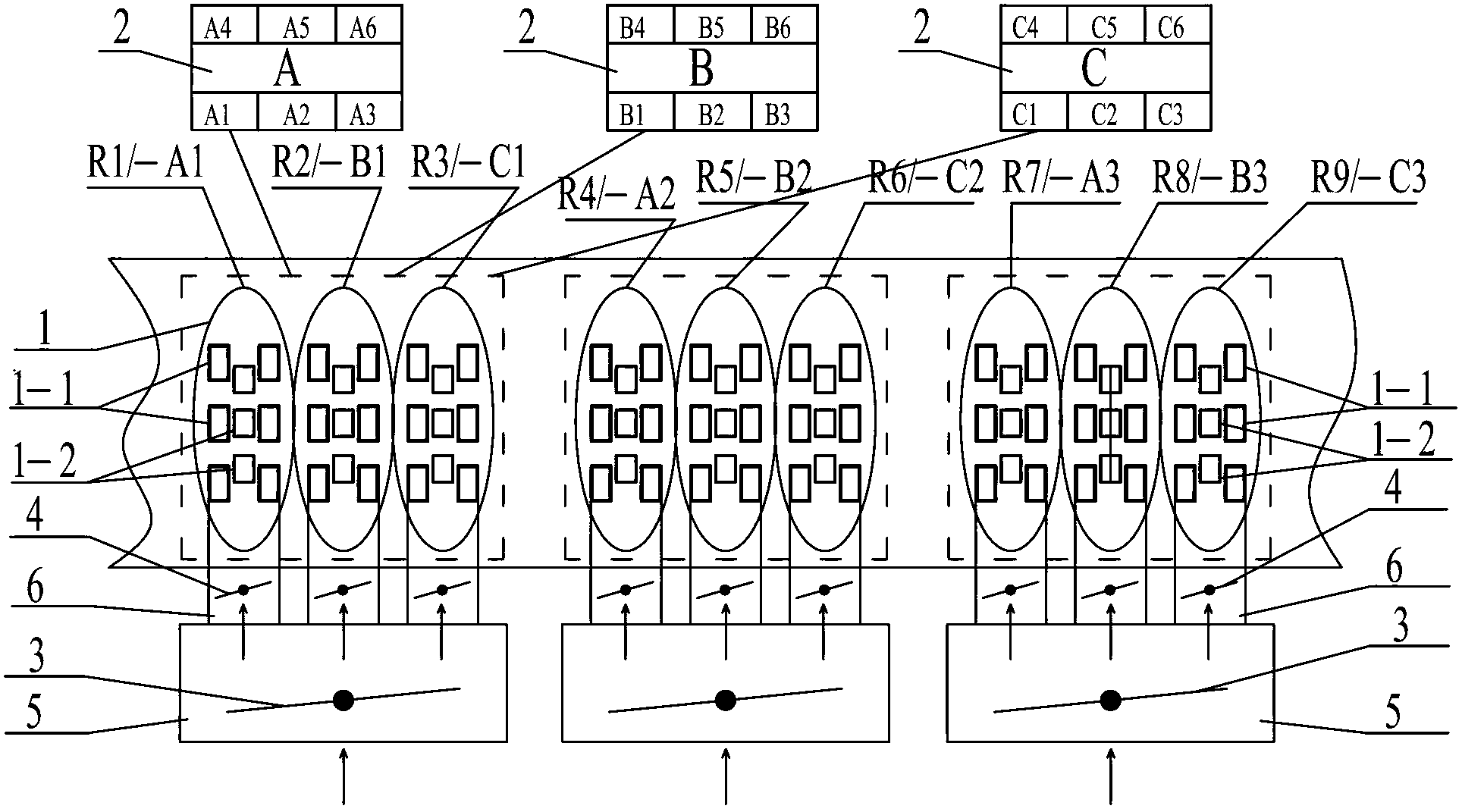

[0012] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a W-flame boiler combustion optimization device in this embodiment includes a W-flame boiler with M burner groups and Y coal mills 2, each burner group includes three burners 1, each Multiple primary air nozzles 1-1 and multiple secondary air nozzles 1-2 are arranged on each burner 1, M burner groups are evenly arranged on the furnace arch, and each coal pulverizer 2 is provided with six supply outlets. At the pulverized coal outlet, the air inlet of each burner group is provided with a secondary wind box 5, and each secondary wind box 5 is provided with a wind box baffle 3, and the bellows baffle 3 is used to control the air volume, and the device also includes multiple A wind chamber 6 and a plurality of wind chamber baffles 4 consistent with the number of wind chambers, an air chamber 6 connected to the two is arranged between each burner 1 and the secondary air wind box 5, an...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 Describe this embodiment, the quantity of the burner group of this embodiment is three, the quantity of the primary air nozzle 1-1 on each burner 1 is four, the secondary air nozzle 1-1 on each burner 1 The number of 2 is four, four primary air nozzles are arranged in 1-1 array, four secondary air nozzles are arranged in 1-2 array, four primary air nozzles 1-1 and four secondary air nozzles 1-2 are parallel to each other It is arranged on each burner 1, and the three burners 1 of each burner group are respectively supplied with pulverized coal by different coal mills 2. In this embodiment, for W flame boilers with primary and secondary air arranged at intervals, this embodiment takes the arrangement of burners in a part of the area on the arch of W flame boilers as an example for illustration, combining figure 1 Note that the number of burner groups in this area is three groups, and the number of corresponding coal...

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 2 Describe this embodiment, the quantity of the burner group of this embodiment is three, the quantity of the primary tuyere 1-1 on each burner 1 is six, the secondary tuyere 1-1 on each burner 1 The number of 2 is three, and there is a row of secondary air nozzles 1-2 between the primary air nozzles 1-1 arranged in two rows, and the number of primary air nozzles 1-1 in each row is three, and each burner group Each of the three burners 1 is fed by different coal mills 2. This embodiment is aimed at the W-flame boiler that adopts multi-injection staged combustion, combining figure 2Note, taking the arrangement of burners in the local area on the W flame boiler arch as an example, the three burners 1 of each burner group are supplied with powder by different coal mills, and each burner is provided with two rows of primary air nozzles 1 -1 and one row of secondary air nozzles 1-2 located in two rows of primary air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com