Rotary air preheater with hierarchical reverse rotation

An air preheater and reverse rotation technology, which is applied in lighting and heating equipment, combustion methods, indirect carbon dioxide emission reduction, etc., can solve the problems of low workmanship capacity and low utilization efficiency of flue gas waste heat, etc., to reduce deviation and reduce heat Deviation, the effect of avoiding condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

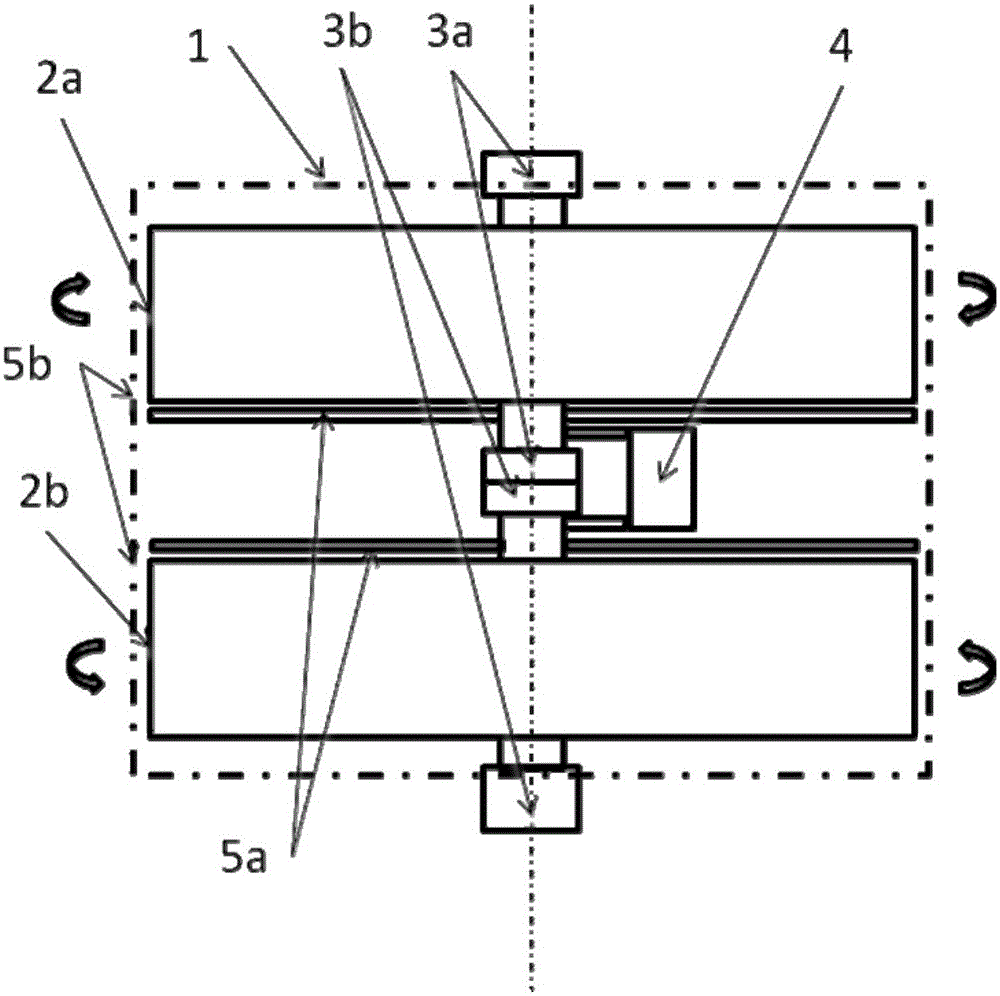

[0013] Working principle of the present invention, concrete structure and a kind of implementation method are further described below in conjunction with accompanying drawing:

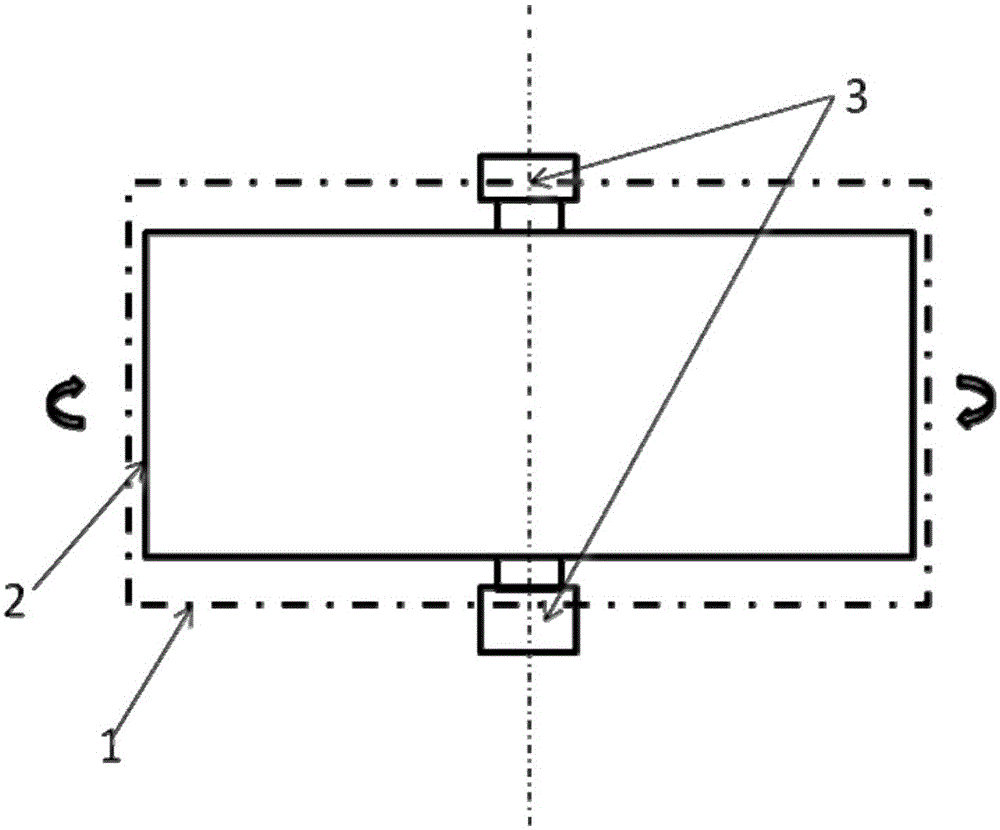

[0014] figure 1 It is a schematic structural diagram of a conventional rotary air preheater, and its basic structure includes a casing 1, a rotor 2, a bearing 3, and a sealing device and other components. The shell, sealing device, inlet and outlet air ducts, and flue divide the rotary air preheater into two parts: the flue gas side and the facing air side. The hot flue gas passes through the flue gas side from top to bottom to heat the rotor in this area, and the heated rotor turns to the air side, thereby heating the air flowing from bottom to top in this area. Since the heated rotor rotates in a clockwise direction and is gradually cooled by the air side, the temperature of the rotor in the air area that passes first is high, and the temperature of the rotor in the air area that passes later is low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com