a heat exchange system

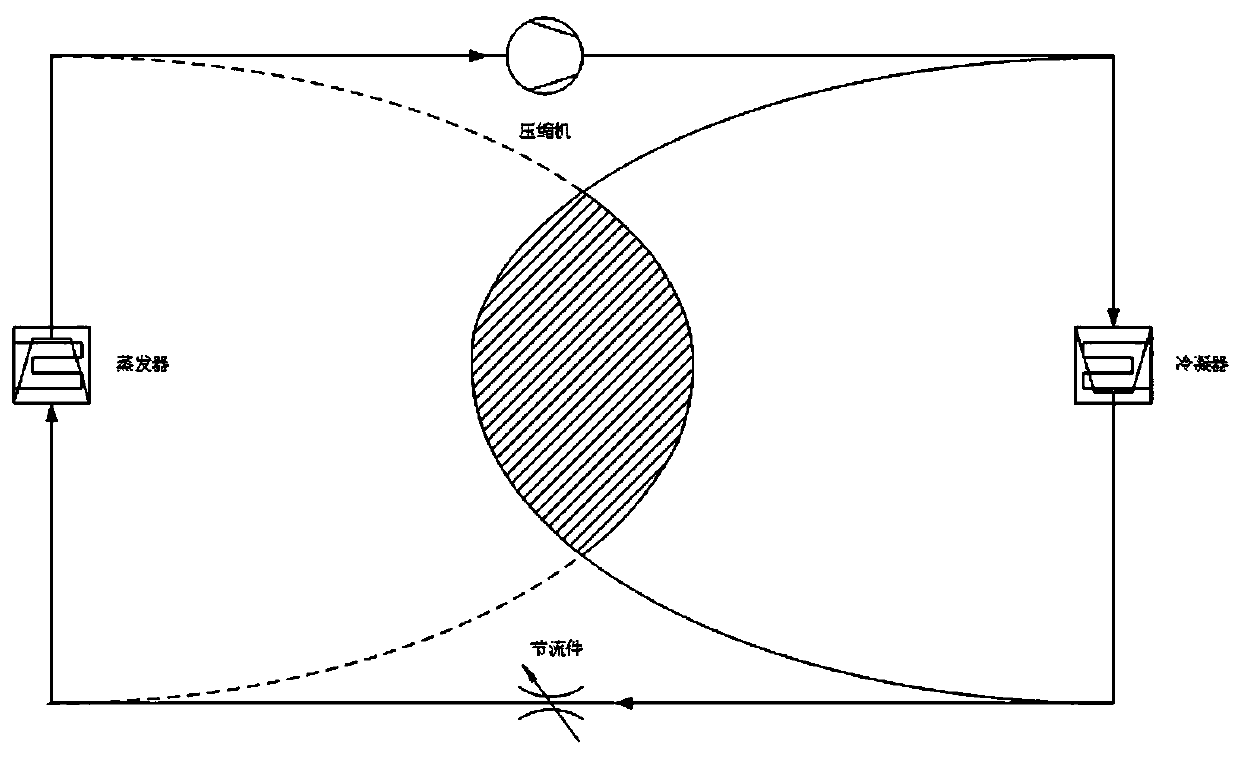

A heat exchange system and heat exchange plate technology, applied in the field of heat exchange, can solve the problems of mutual infection between the condensation area and the evaporation area, damage to the evaporation scene of the evaporator, and failure to achieve optimal energy efficiency, so as to increase the temperature difference, improve efficiency, and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

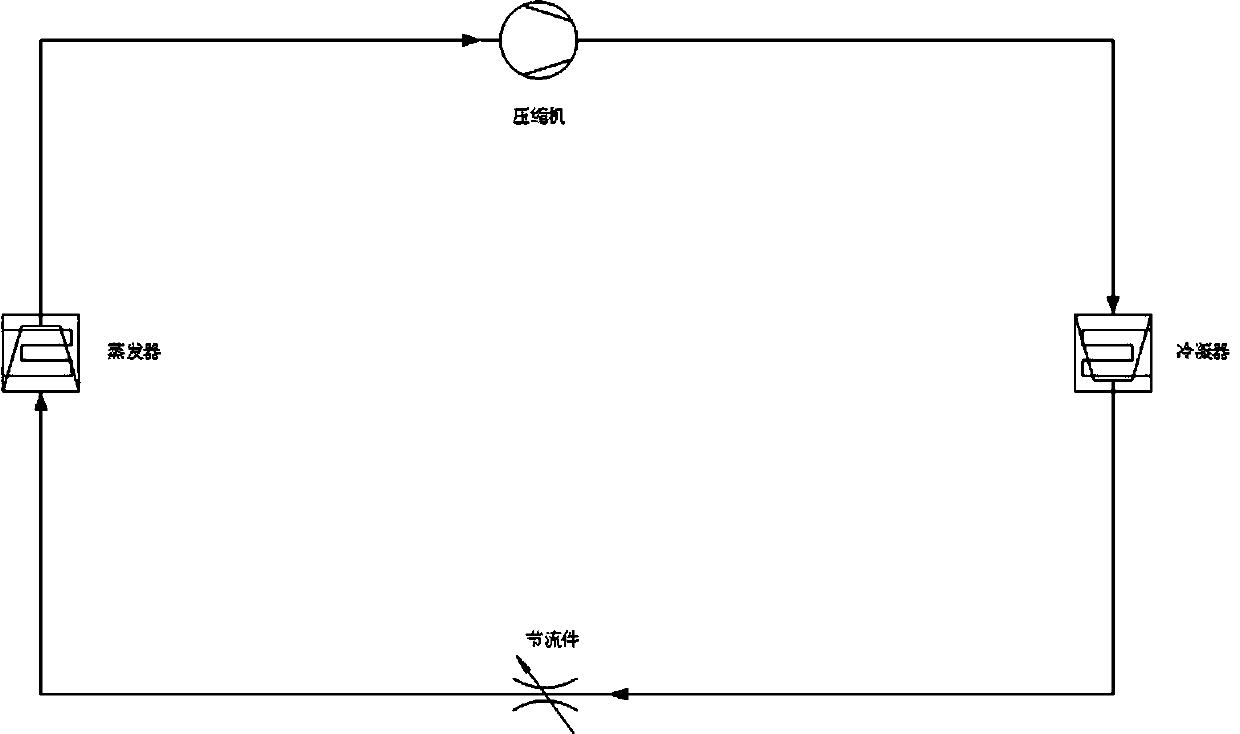

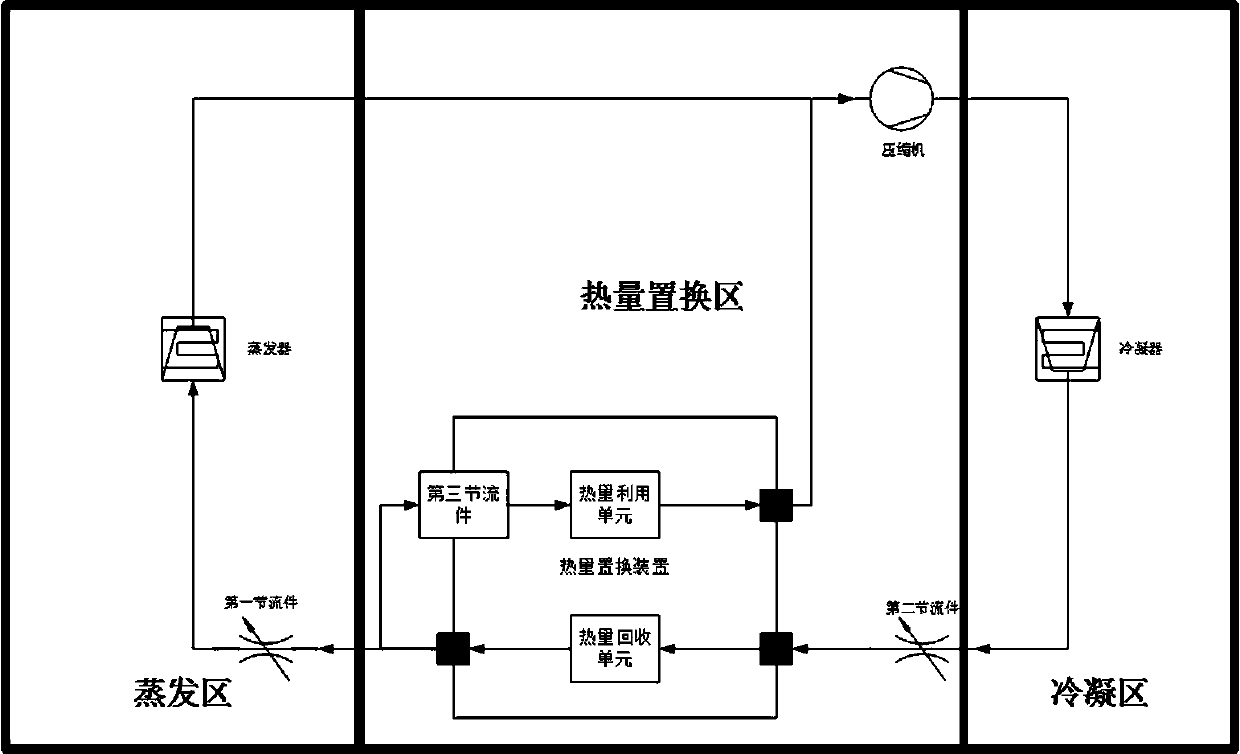

[0040] like Figure 4 It is a heating system, including a compressor, a condenser, an evaporator, a first throttling piece, a second throttling piece, and a heat replacement device connected through a working medium flow channel. The outlet of the compressor is connected to the inlet of the condenser, the outlet of the condenser is connected to the inlet of the second throttle, the outlet of the third throttle is connected to the inlet of the heat displacement device, and the first outlet of the heat displacement device is connected to the first throttle The inlet of the part, the outlet of the first throttling part is connected to the inlet of the evaporator, and the outlet of the evaporator is connected to the suction port of the compressor. When the working medium flows in the working medium flow channel, it absorbs the heat from the external environment of the evaporator and releases it into the environment where the condenser is located, providing heat for the environment...

Embodiment 2

[0049] like Figure 5 It is a heating system, including a compressor, a condenser, an evaporator, a first throttling piece, a second throttling piece, and a heat replacement device connected through a working medium flow channel. Among them, the evaporator includes an ordinary evaporator and a heat collecting plate (a heteropolymer heat absorbing plate that absorbs heat passively). The outlet of the compressor is connected to the inlet of the condenser, the outlet of the condenser is connected to the inlet of the second throttle, the outlet of the third throttle is connected to the inlet of the heat displacement device, and the first outlet of the heat displacement device is connected to the first throttle The inlet of the part, the outlet of the first throttling part is connected to the inlet of the evaporator, and the outlet of the evaporator is connected to the suction port of the compressor. When the working medium flows in the working medium flow channel, it absorbs the ...

Embodiment 3

[0053] like Figure 6 It is a heating system, including a compressor, a condenser, an evaporator, a first throttling piece, a second throttling piece, and a heat replacement device connected through a working medium flow channel. Among them, the evaporator includes an ordinary evaporator and a heat collecting plate (a heteropolymer heat absorbing plate that absorbs heat passively). The outlet of the compressor is connected to the inlet of the condenser, the outlet of the condenser is connected to the inlet of the second throttle, the outlet of the third throttle is connected to the inlet of the heat displacement device, and the first outlet of the heat displacement device is connected to the first throttle The inlet of the part, the outlet of the first throttling part is connected to the inlet of the evaporator, and the outlet of the evaporator is connected to the suction port of the compressor. When the working medium flows in the working medium flow channel, it absorbs the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com