A system that drives a liquid working medium to do work by vapor pressure

A technology of vapor pressure and working medium, which is applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of low thermal efficiency, low-temperature heat energy discharge, etc., and achieve the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

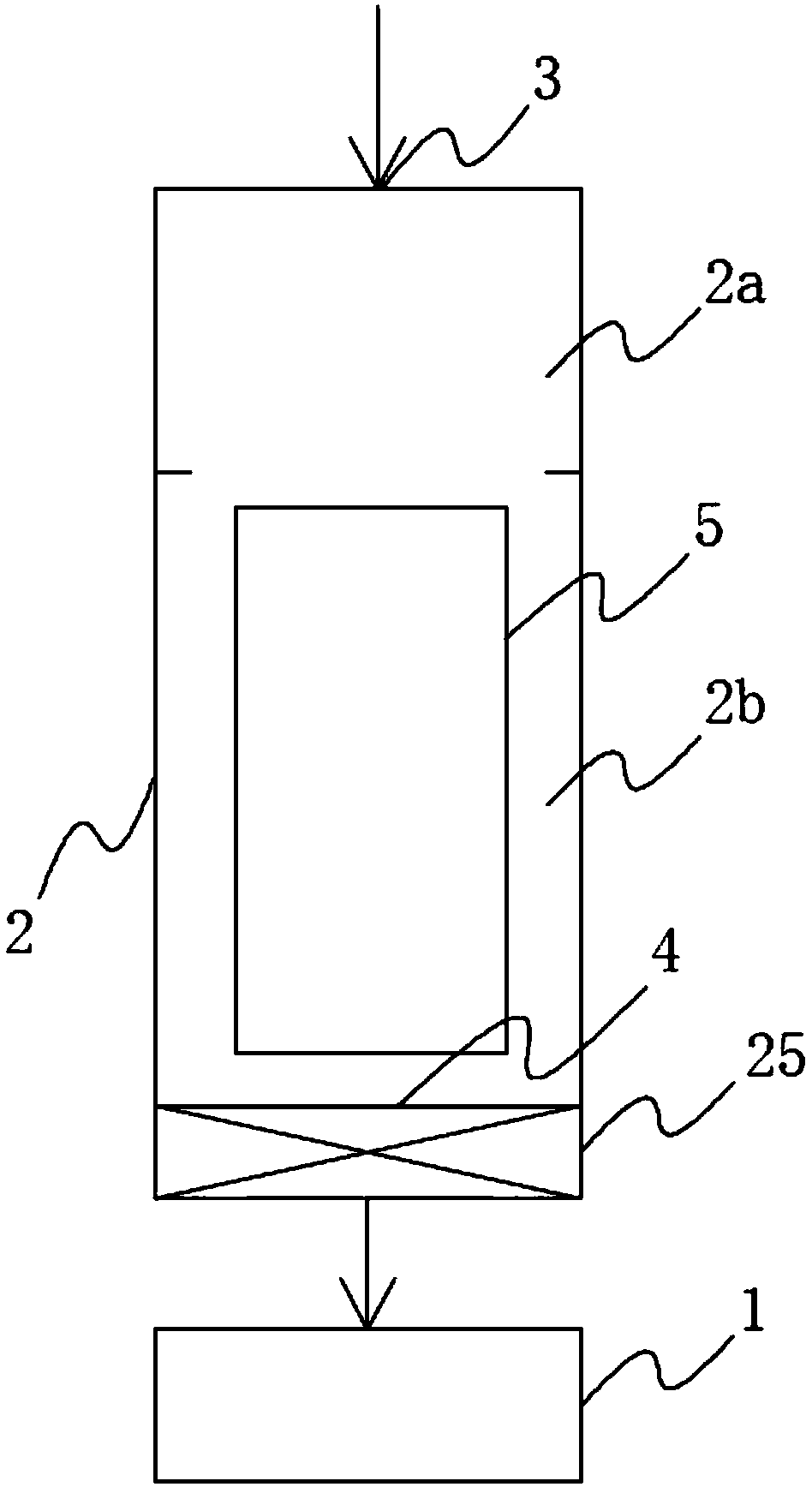

[0028] like figure 1 As shown in , a system for driving a liquid working medium to do work by vapor pressure according to the present invention includes a work device 1 and a diversion channel 2, and the diversion channel 2 includes a steam chamber 2a and a liquid chamber communicated with each other 2b, the steam chamber 2a is located above the liquid chamber 2b; a working medium inlet 3 communicating with the steam chamber 2a and a working medium outlet 4 communicating with the liquid chamber 2b are provided on the diversion channel 2; the working device 1 and the working medium The medium outlet 4 is connected; a cooling device 5 for cooling the working medium is arranged between the working medium inlet 3 and the working medium outlet 4 in the diversion channel 2 . Wherein, the work device 1 can be a power generating device or a mechanical power device, and the power for doing work is provided by the liquid working fluid discharged from the working medium outlet 4 on the f...

specific Embodiment approach 2

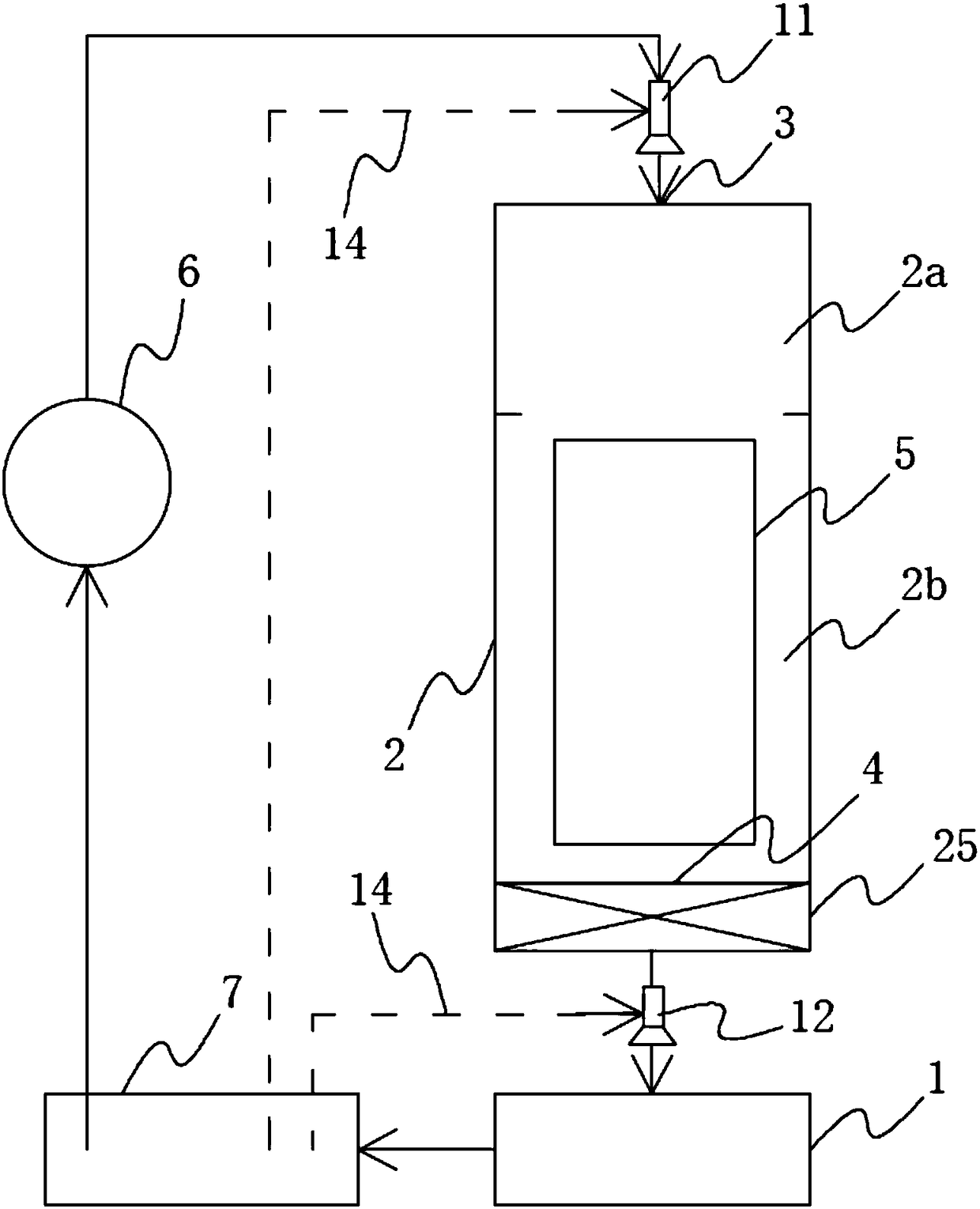

[0032] Refer to attached figure 2 As shown in , on the basis of the above specific embodiment 1, the system also includes a heat source 6 and a working medium pool 7, wherein the working medium pool 7 is connected with the work device 1 to collect the liquid working medium after passing through the work device 1 ; The heat source 6 is connected to the working fluid inlet 3 on the working fluid pool 7 and the diversion channel 2 respectively through pipelines. In this way, by introducing the corresponding heat source 6 on the basis of the specific embodiment 1, the liquid working medium collected in the working medium pool 7 after passing through the work device 1 can be directly reheated through the heat source 6 to form high-temperature and high-pressure steam Or the high-temperature liquid is added into the diversion channel 2 again through the working medium inlet 3, so as to realize the circulation of the system. The heat source 6 can be a device that heats the liquid wo...

specific Embodiment approach 3

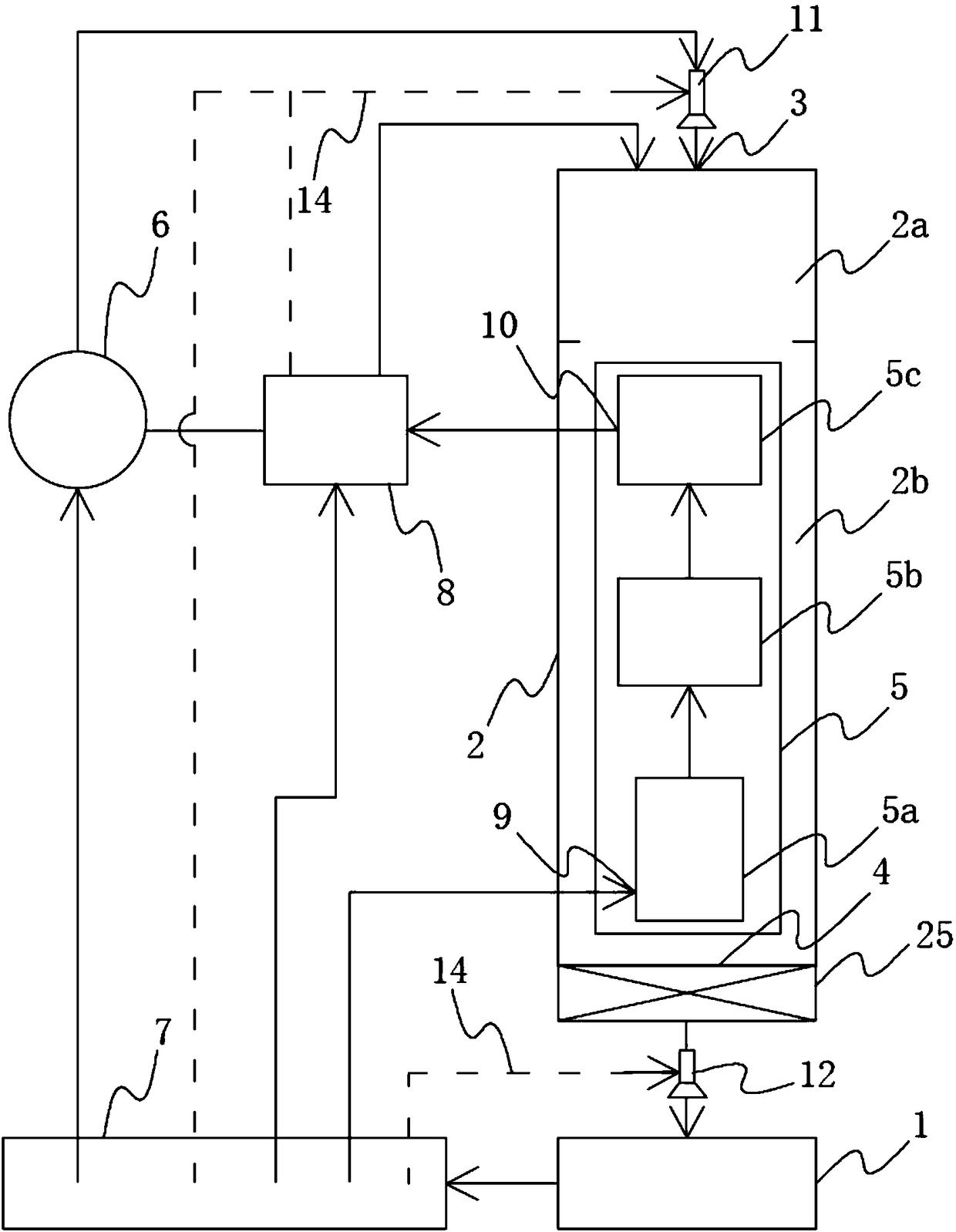

[0033] In the above-mentioned specific embodiment 1 and specific embodiment 2, the function of the cooling device 5 is to cool down the high-temperature working fluid in the diversion channel 2 . In order to further recycle the energy released in the cooling process to improve energy utilization; refer to the attached image 3 As shown in , on the basis of the above-mentioned specific embodiment 2, a heating container 8 is further provided; the cooling device 5 includes at least one heat exchanger, and the cooling device 5 is provided with heat exchangers respectively communicated with the heat exchanger An inlet 9 and a heat exchange outlet 10, the heat exchange inlet 9 is connected to the working medium pool 7 through a pipeline; the heating container 8 is connected to the working medium pool 7 and the heat exchange outlet 10 on the cooling device 5 through a pipeline; The heat source 6 is connected to a heating container 8 . At this time, the low-temperature liquid working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com