Hot gas turbine

A hot gas and turbine technology, used in gas turbine devices, mechanical equipment, engine components, etc., can solve the problems of difficult to further improve thermal efficiency, high material cost, high construction cost, and achieve the effect of reduced flow resistance, reasonable structural design, and reduced cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

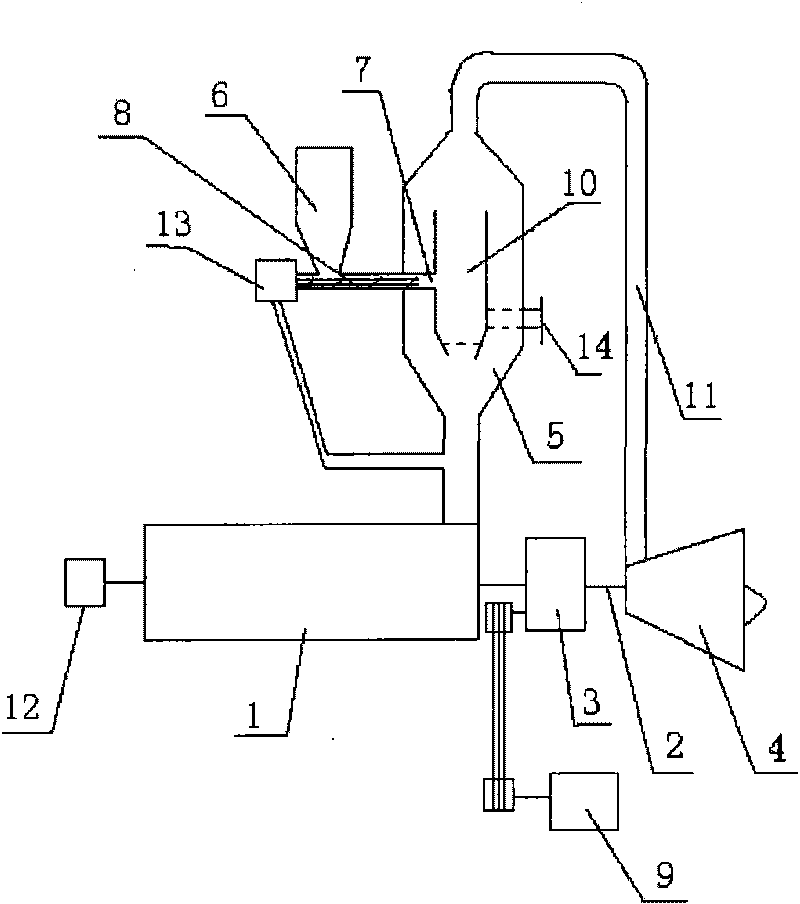

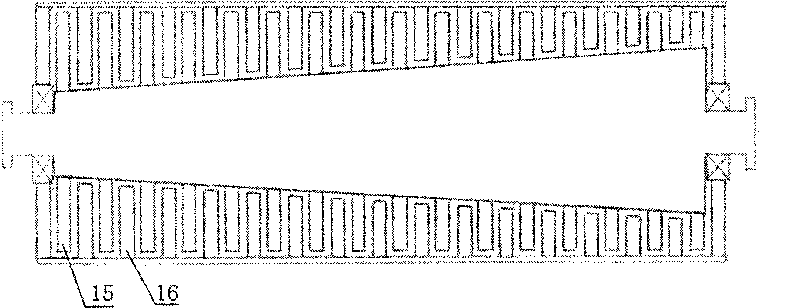

[0018] A kind of heat turbine of the present embodiment refers to the appended figure 1 , 3 , including a compressor 1 connected to the driving device 12 and densely covered with rotor blades 15 and stator blades 16 inside, the output end of the compressor 1 communicates with the cold air channel 5 with a fuel combustion chamber 10 inside, and the combustion chamber 10 is A fuel delivery device is provided, the cold air channel 5 is connected with the hot gas turbine 4 through the gas and cold air mixed hot gas pipeline 11, and a speed reducer 3 is installed between the heat gas turbine 4 and the compressor 1, and the speed reducer 3 is connected with a load 9; The machine 3 is connected with the hot gas turbine 4 and the compressor 1 through the transmission shaft 2; the fuel delivery device includes a power transmission device 13 connected to the output end of the compressor 1, and the power transmission device 13 drives the fuel delivery device 8 connected thereto to work, ...

Embodiment 2

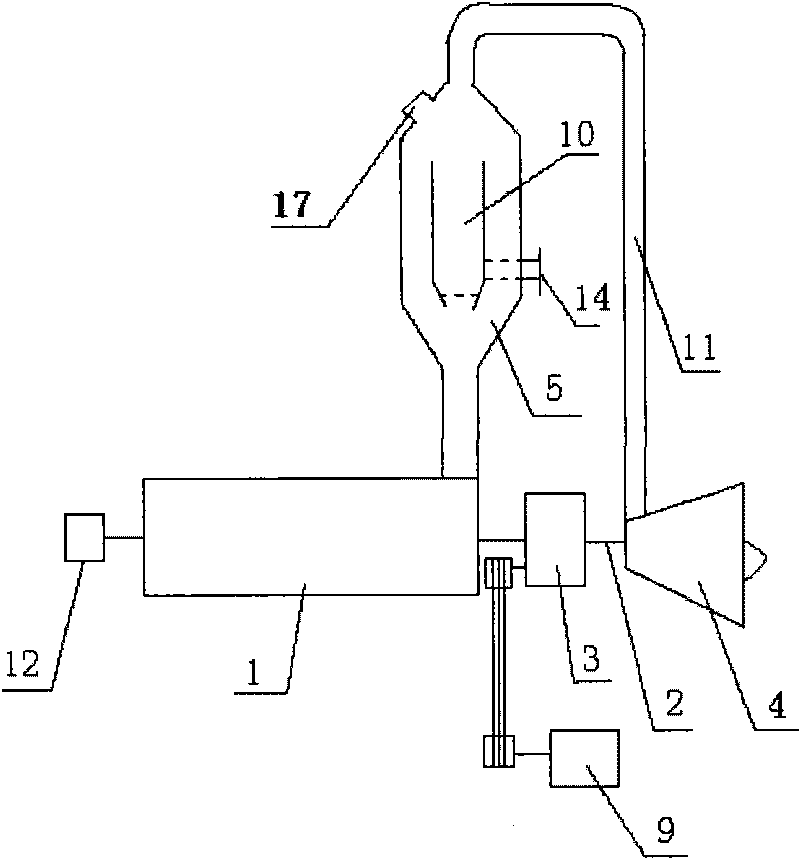

[0020] The difference between this embodiment and Embodiment 1 is that the fuel delivery device is the feed port 17 provided on the cold air channel 5 .

[0021] Working principle: the driving device 12 drives the compressor 1 to work, the compressed air enters the cold air passage 5, and the fuel combustion chamber 10 is arranged in the cold air passage 5, and the fuel is sent into the combustion chamber 10 through the fuel delivery device, and the fuel is in the combustion chamber After combustion, high-heat gas will be produced, and the gas will be mixed with the compressed cold air to reduce the temperature of the gas, and the gas and cold air will be sprayed to the hot gas turbine 4 through the gas and cold air mixed hot gas pipeline 11, driving the hot gas turbine 4 to run at a high speed. The temperature of the gas working medium is lower, so that the service life of the blades of the hot gas turbine is increased, and the cost of blade materials is reduced. The turbine o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com