Refrigerating circulation system of high-temperature air conditioner and high-temperature air conditioner

A circulation system and refrigeration cycle technology, applied in the direction of refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve the problems of not greatly increasing the cost of air conditioning, poor air conditioning capacity and performance, etc., to reduce the workload and reduce the workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

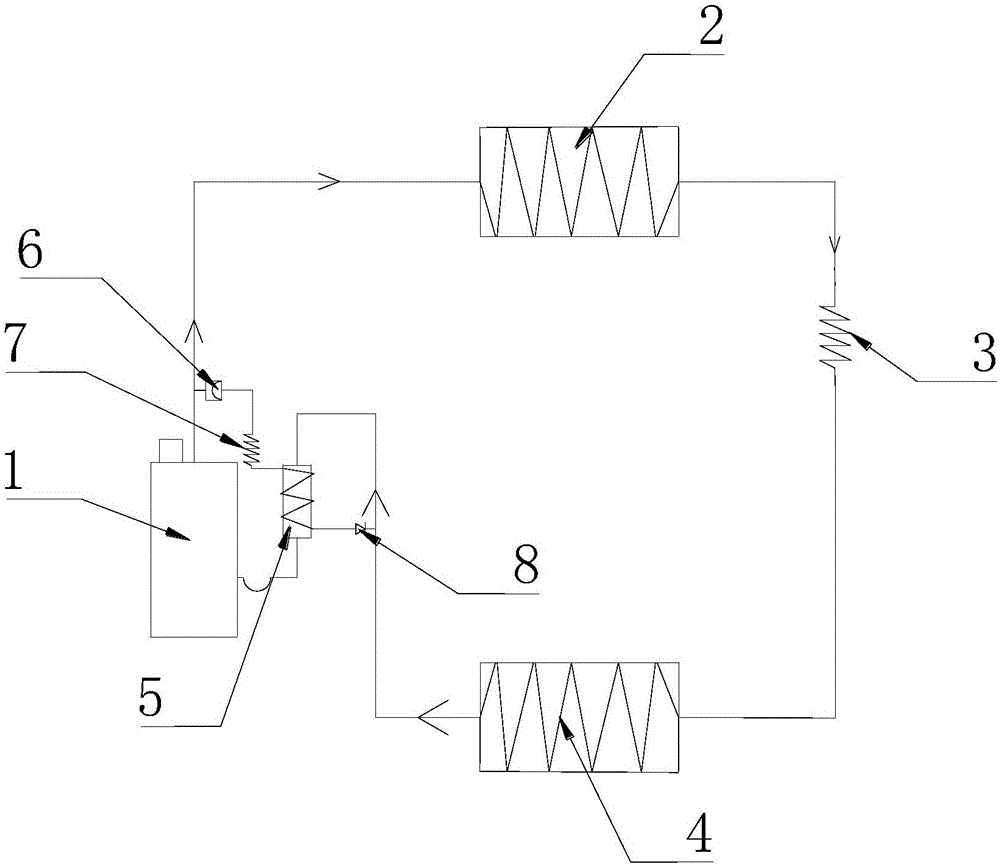

[0031] like figure 1 As shown, the refrigerating cycle system of a high-temperature air conditioner in this embodiment includes a compressor 1, an outdoor heat exchanger 2, a capillary tube 3, an indoor heat exchanger 4, and a gas-liquid separator 5 that are sequentially connected to form a circuit; wherein, the compressor The working medium outlet of 1 is connected with the working medium inlet of outdoor heat exchanger 2 through pipes, the working medium outlet of outdoor heat exchanger 2 is connected with the working medium inlet of indoor heat exchanger 4 through capillary 3, and the indoor heat exchanger 4 The working medium outlet of the gas-liquid separator 5 communicates with the working medium inlet of the gas-liquid separator 5 through a pipeline, and the working medium outlet of the gas-liquid separator 5 communicates with the working medium inlet of the compressor 1 through a pipeline. The refrigerating cycle system of a high-temperature air conditioner in this emb...

Embodiment 2

[0036] like figure 1 As shown, a refrigeration cycle method of a high-temperature air conditioner in this embodiment includes the following steps:

[0037] S1, under high-temperature conditions, a part of the working fluid discharged from the compressor 1 is circulated sequentially through the circulation loop formed by the outdoor heat exchanger 2, the capillary tube 3, the indoor heat exchanger 4, the gas-liquid separator 5 and the compressor 1;

[0038] S2, another part of the working fluid discharged from the compressor 1 enters the gas-liquid separator 5 through the pressure relief device, and the gas-liquid separator 5 performs gas-liquid separation on the part of the working fluid.

[0039] In S2 of this embodiment, another part of the compressed working fluid discharged from the compressor 1 passes through the unloading valve 6 and the pressure relief capillary 7 in sequence, and then flows into the working fluid discharged from the indoor heat exchanger 4 after being ...

Embodiment 3

[0043] like figure 1 As shown, a high-temperature air conditioner in this embodiment includes the refrigeration cycle system described in Embodiment 1. figure 1 The direction of the arrow in is the flow direction of the working fluid.

[0044] The working principle of the present invention is: in normal working conditions (outdoor temperature is 20°C-40°C), the unloading valve does not work and is in a closed state, and the working fluid circulates according to the normal working conditions; in high temperature working conditions (outdoor temperature is When the discharge pressure of the compressor is greater than the setting pressure of the unloading valve, most of the working fluid discharged from the compressor 1 still flows into the outdoor heat exchanger for regular circulation, the unloading valve is opened, and it is in working condition, a small amount The working fluid passes through the unloading valve, throttling through the pressure relief capillary to exchange he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com