Air-source heat-pump air heater adopting parallel-type evaporator

An air source heat pump and evaporator technology, which is applied to compressors, compressors, refrigerators, etc. with multiple evaporators, can solve the problems of inability to meet people's heating requirements, high operating costs of electric heating, and waste of electric energy. Achieve the effect of favoring water evaporation, improving heat transfer capacity and improving energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

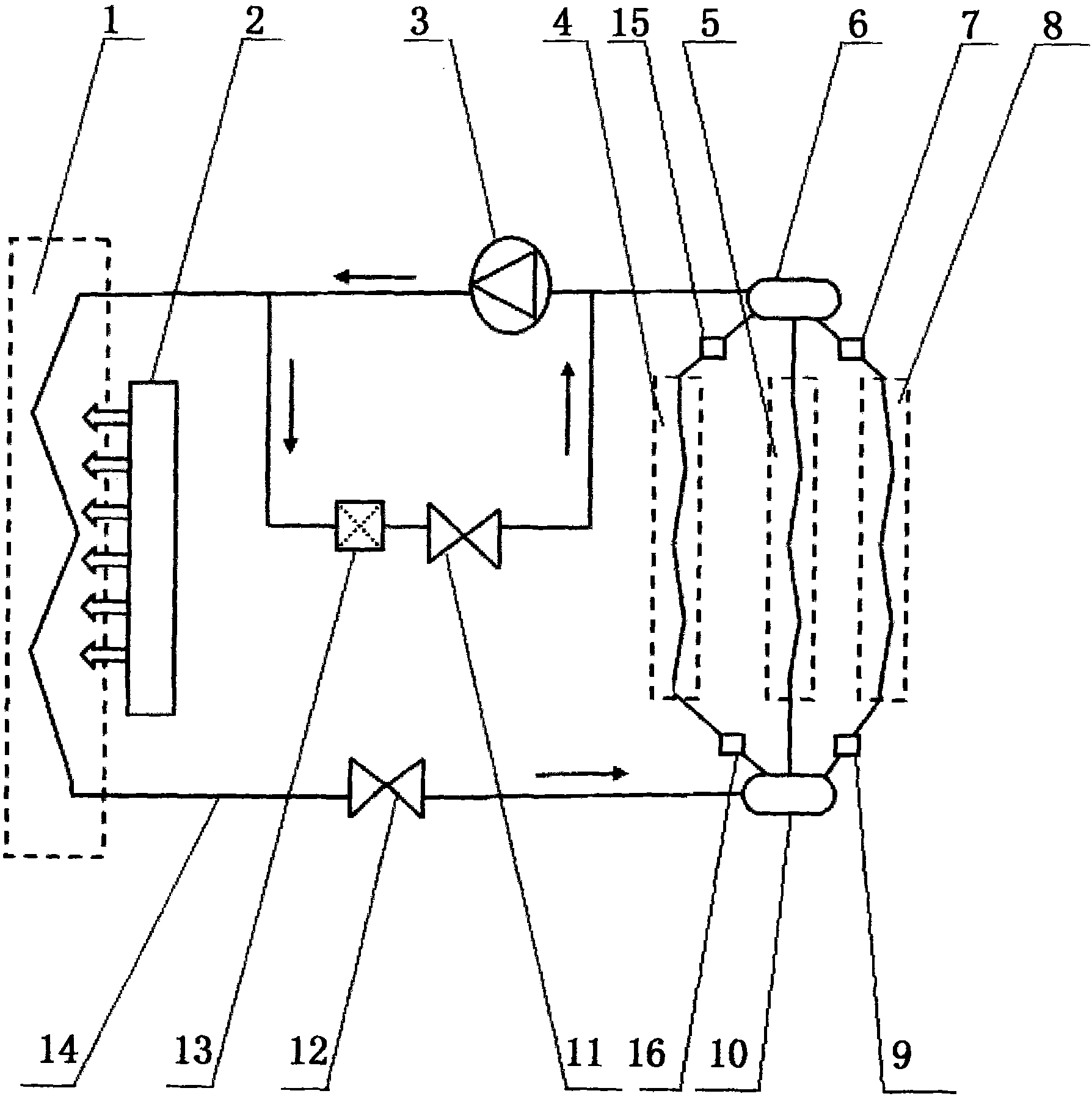

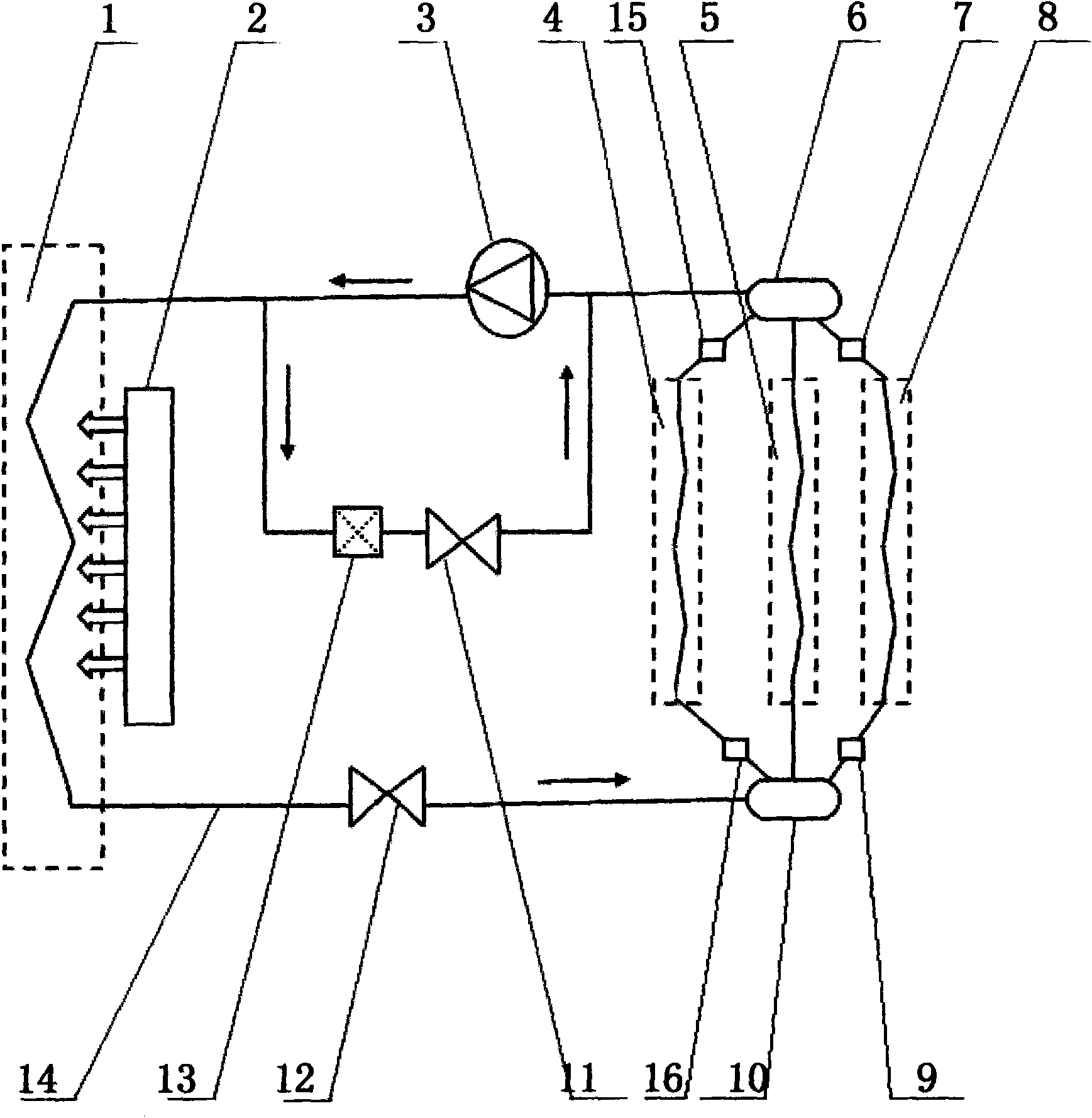

Embodiment 1

[0021] Embodiment 1: In order to illustrate the actual effect of the present invention, at an ambient temperature of 7° C., the air source heat pump air blower is used to heat the drying room provided with the heat preservation layer by means of circulating air. Dimensions of drying room: length 4.92m, width 3.64m, height 2.2m; total rated power of air source heat pump fan unit is 5.37kw, compressor power is 4.68kw, condenser fan power is 0.37kw, evaporator fan is 0.3kw, condenser heat exchange Area 37.5m 2 , the working medium is 417A.

[0022] Adopt a set of heat exchange area of 32.8m 2 evaporator, the temperature in the drying room can only reach 50°C; add a set of heat exchange area of 30.8m 2 The evaporator absorbs heat, and the temperature of the drying room reaches 64°C.

Embodiment 2

[0023] Example 2: Use an air source heat pump to heat, and bake the middle tobacco leaves at an ambient temperature of 25°C-36°C. The specifications of the drying room are: length 4.2m, width 2.7m, height 3.4m, and a condenser fan with a power of 1.5KW Advanced two-speed suction fan, compressor input power 6KW, evaporator area 36m 2 , the evaporator fan is 250W, and the heat exchange area of the condenser is 48.6m 2 , The baking time is 104 hours, the power consumption is 531 degrees, the dried tobacco leaves are 155kg, and the power consumption for drying one kilogram of dry tobacco leaves is 3.42 degrees / kg.

[0024] In order to compare the effects of the above inventions, under the same drying room conditions, only resistance elements are used to generate heat for heating, the baking time is 102 hours, the power consumption reaches 923 degrees, the dried tobacco leaves are 156kg, and the power consumption for baking one kilogram of dry tobacco leaves is 6.23 degrees / kg. ...

Embodiment 3

[0027] Example 3: In order to test the heating effect under different ambient temperatures, the air source heat pump adopting the above technical solution was placed in the freezer for experiments. The input power of the air source heat pump compressor was 5.75kw, and the total power of the whole machine was 6.3kw. The heat exchange area of the first group of evaporators is 49.5m 2 , the heat exchange area of the second group of evaporators is 46m 2 , the heat exchange area of the third group of evaporators is 41.4m 2 , condenser heat exchange area 44.8m 2 , the air volume at the air outlet is 5450m 3 / h. In order to eliminate the interference of circulating heating on the experimental data, the condenser and its fan were placed in an empty workshop outside the freezer, and the ambient temperature was 35°C. The experimental results are as follows:

[0028] 1. When the temperature of the freezer is 6°C, only the first group of evaporators is activated, and the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com