Tape speed control method for high drop height heavy type belt conveyor

A control method and belt conveyor technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., to achieve the effects of saving equipment and funds, good direct economic benefits, and economic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

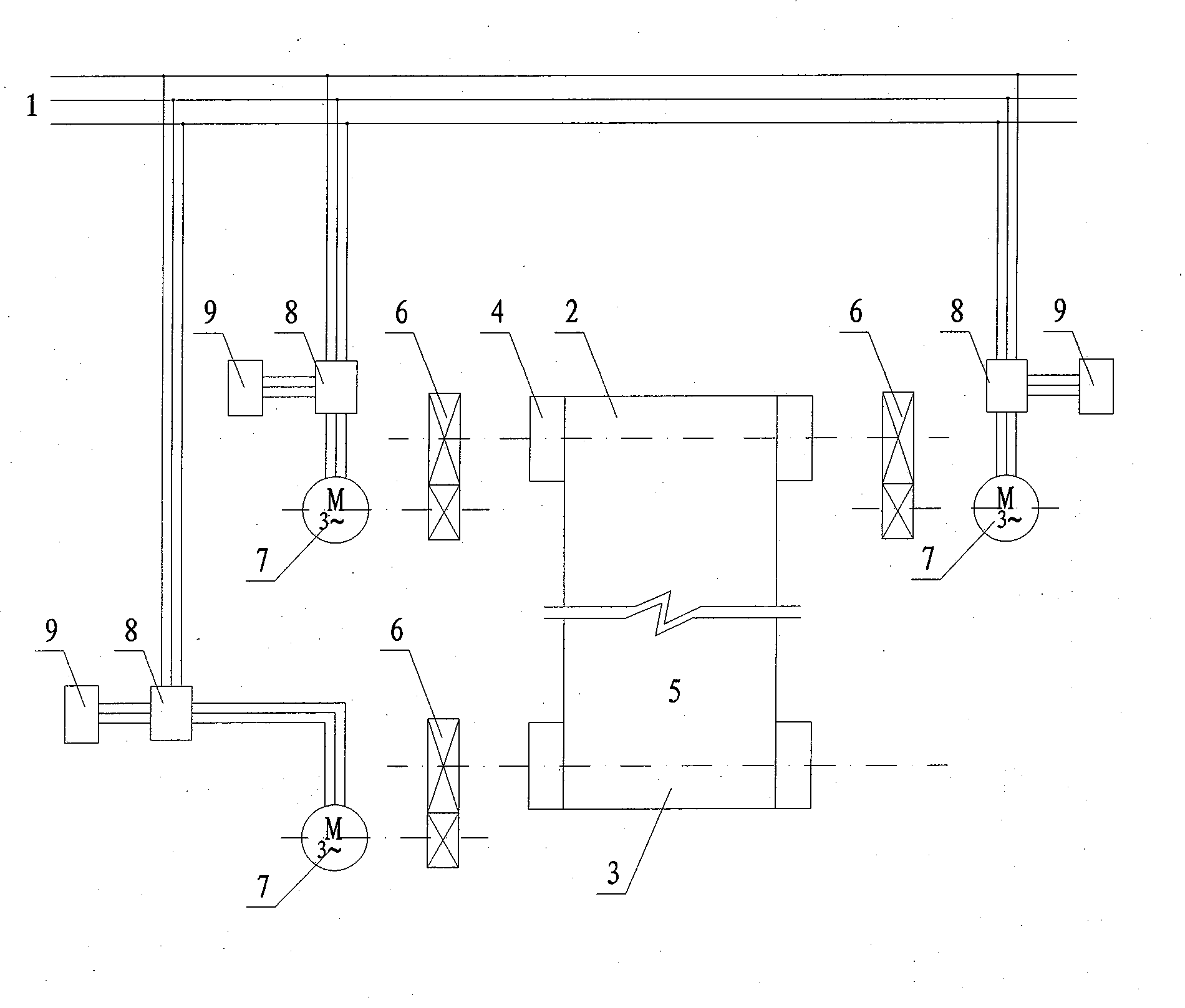

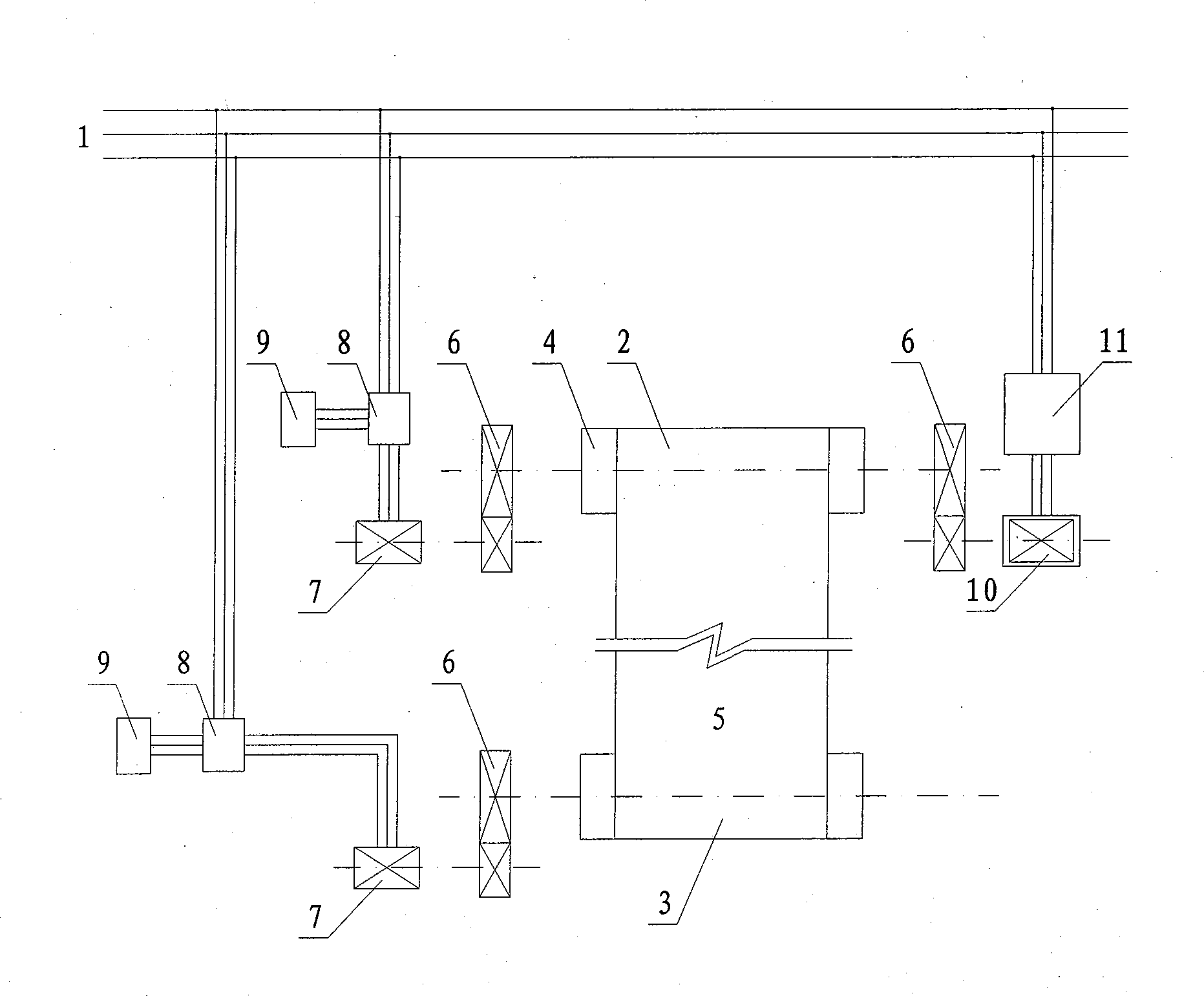

[0022] The facility mode of the present invention will be further described in detail below in conjunction with the accompanying drawings.

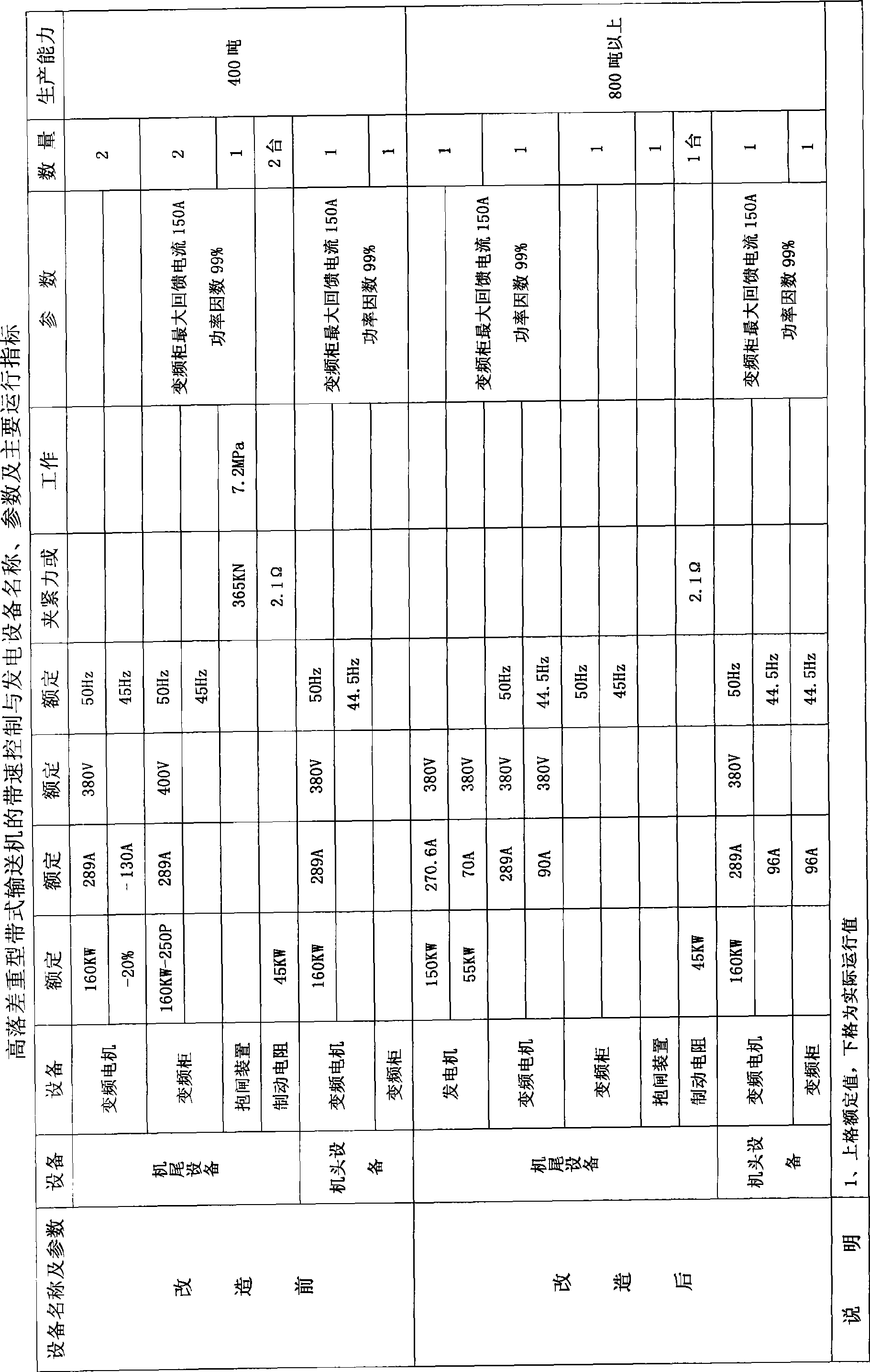

[0023] Such as figure 1 to combine figure 2 Shown: present embodiment is mainly made up of belt conveyor machine tail 2, belt conveyor machine head 3, belt conveyor roller 4, conveyor belt 5, speed reducer 6, variable frequency motor 7, frequency converter 8 and frequency converter in existing Based on the structure of the high-drop heavy-duty belt conveyor composed of resistors 9, one of the two 160kW variable-frequency motors 7 originally installed at the tail 2 of the belt conveyor to drive the rotation of the belt conveyor roller 4 is an inverter 8 and frequency converter resistance 9 are removed as a backup, and a generator 10 and a voltage stabilization adjustment feedback circuit (unit) 11 are configured in addition. What the voltage stabilization adjustment feedback circuit (unit) 11 adopts is a conventional circuit, and its fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com