Device, system, and method for securing an irregularly shaped device, including those with discontinuous contours, in a fixture

a technology of irregular shape and fixture, applied in the direction of load securing, transportation and packaging, transportation items, etc., can solve the problems of not providing the accessibility required to meet the above stated criteria, not readily adaptable to existing tooling or commercially available fixtures, and not readily adaptable to existing commercially available fixtures. , to achieve the effect of saving capital equipment, training and maintenance, and cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

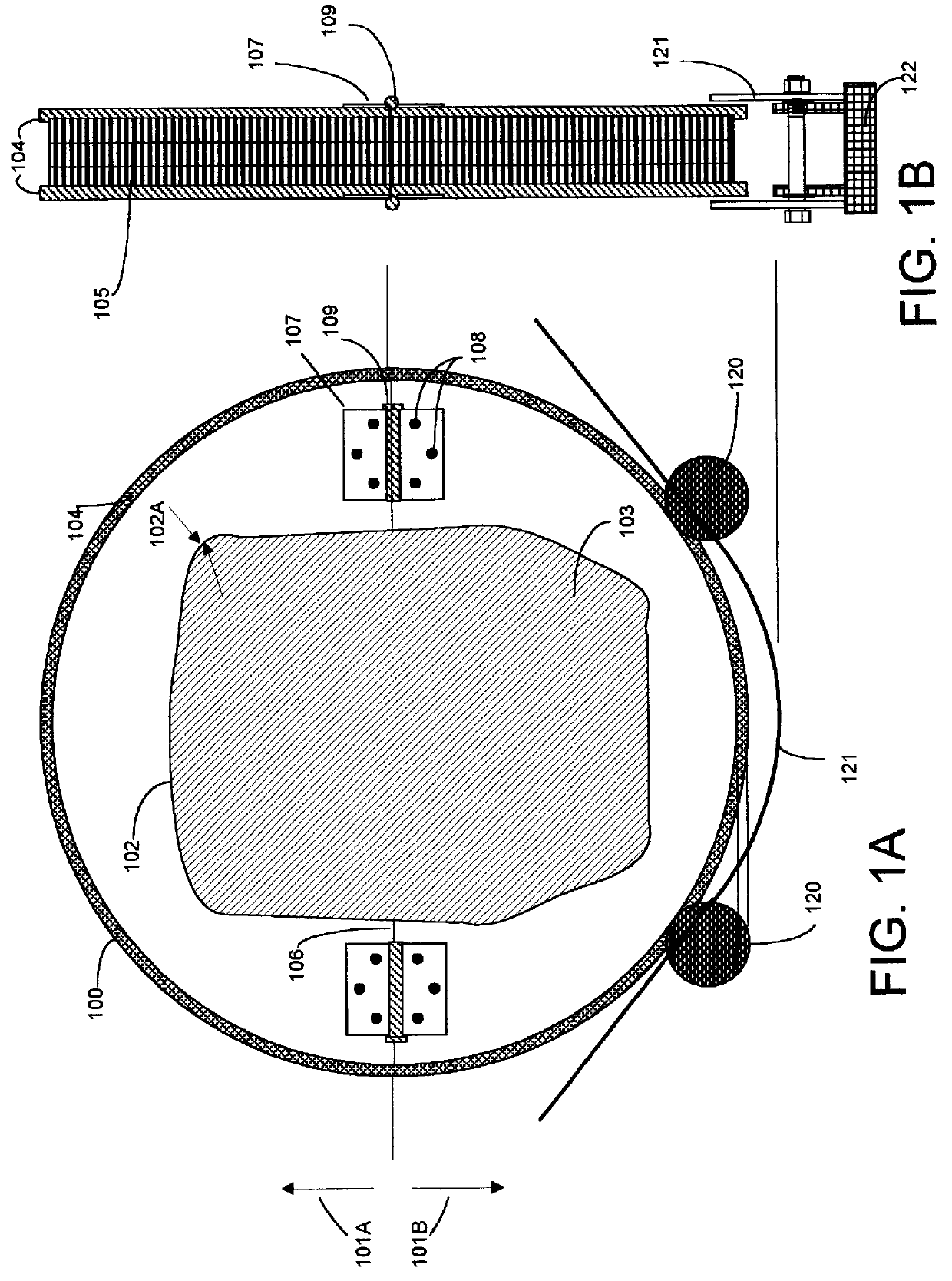

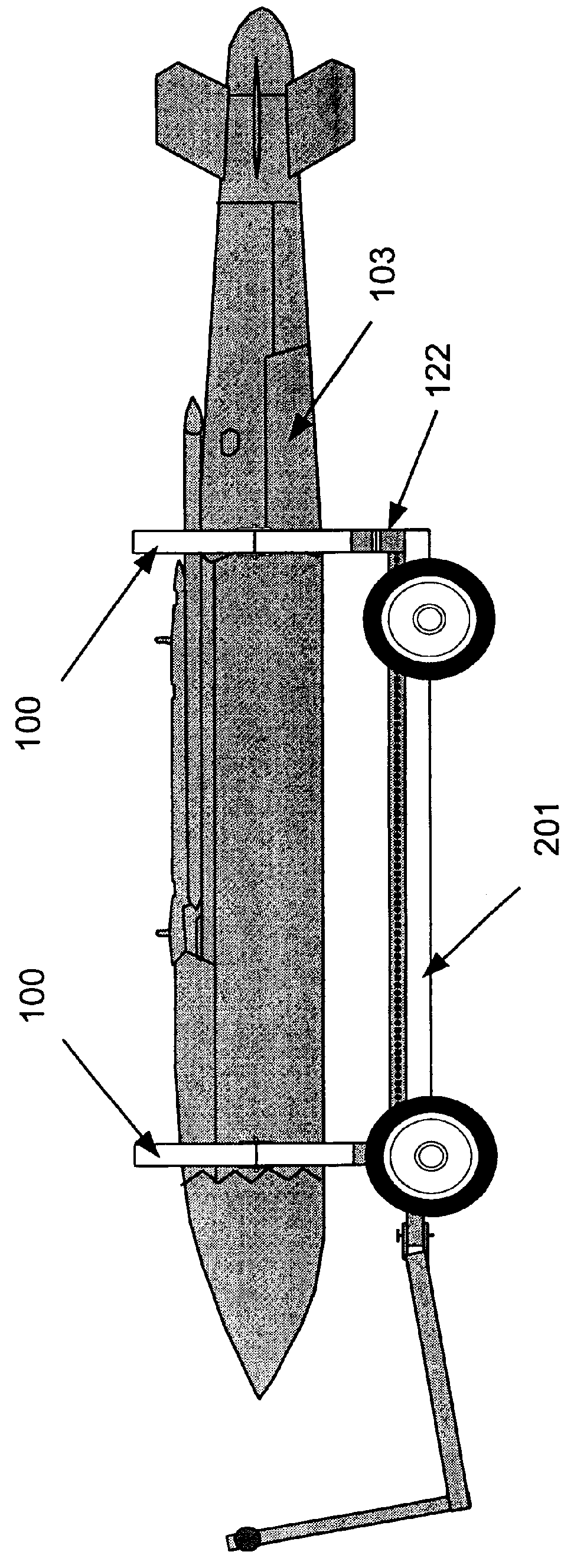

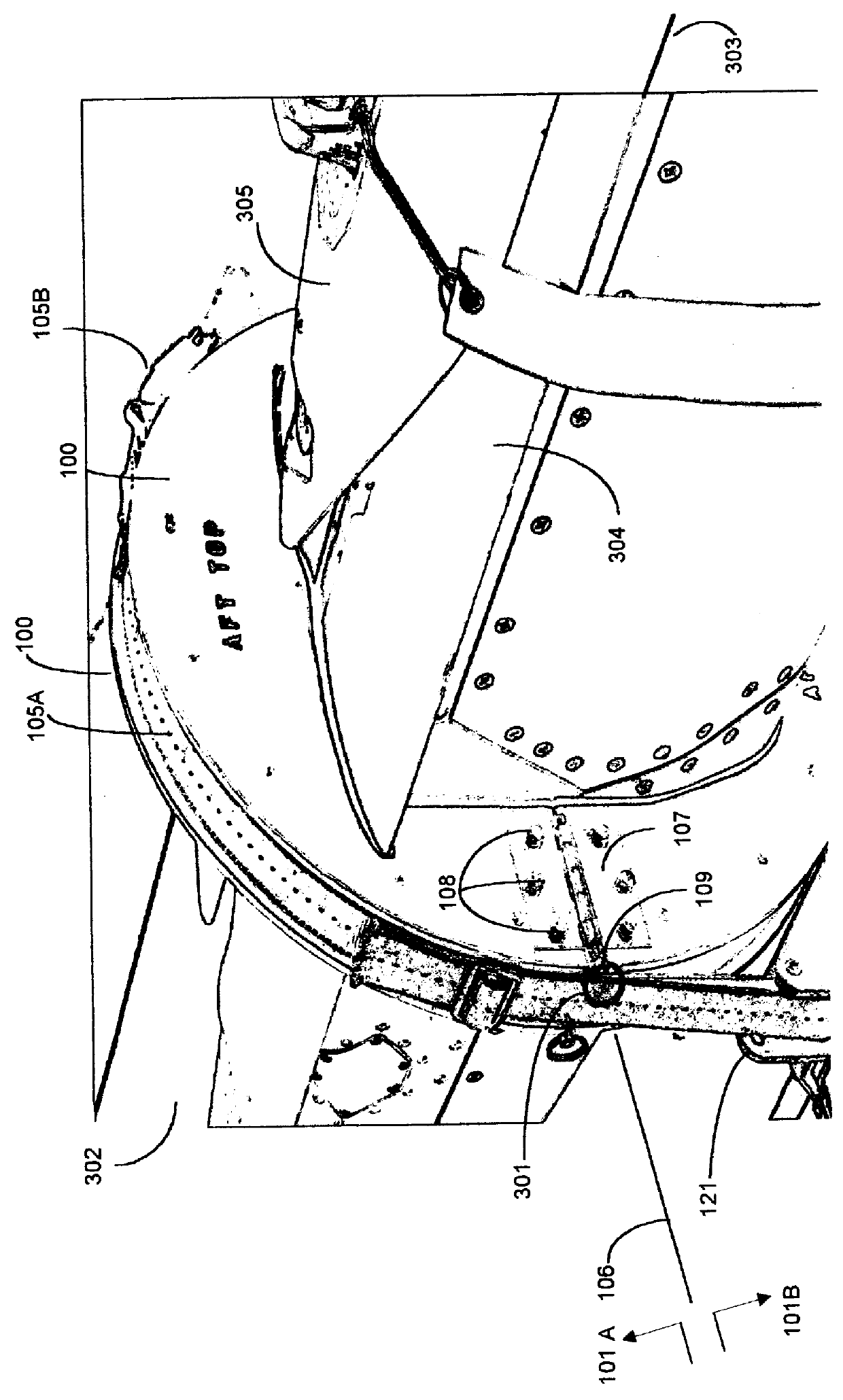

A preferred embodiment of the present invention, locally known as the "JSOW Rollover Fixture," a composite of components 401A, 401B, 402 and 600, is depicted on end as the apparatus 100 of FIG. 1 and in plan view supporting the JSOW in two places, using inserts 401A and 401B, along its long axis 303 as in FIG. 4. It incorporates a pair of fixture inserts or adapters 401A and 401B that permit rotation of the AGM-154 (JSOW) weapon 302, thus providing direct access to the onboard Test Instrumentation Kit (TIK) (not separately shown). The JSOW weapon 302 is heavy, bulky, irregularly shaped, and also discontinuous in contour in places along the contour of its long axis 303. There are two parts to the interface 101A and 101B with the roller balls 120 of two AERO-58A Skid Adapters 600, shown in FIG. 6 with roller balls 120 set on maximum spacing 604A, in turn mounting to an MHU-191M Munitions Transporter 402 in FIG. 4.

The JSOW Rollover Fixture 401A, 401B, 402 and 600 is a non-lifting, non-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com