Winding wire taping method and winding wire taping control device

A technology of control device and winding wire, which is applied to control electromechanical transmission device, coil manufacturing, control system, etc., to achieve the effect of precise pitch control, precise tension control, and elimination of pitch variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

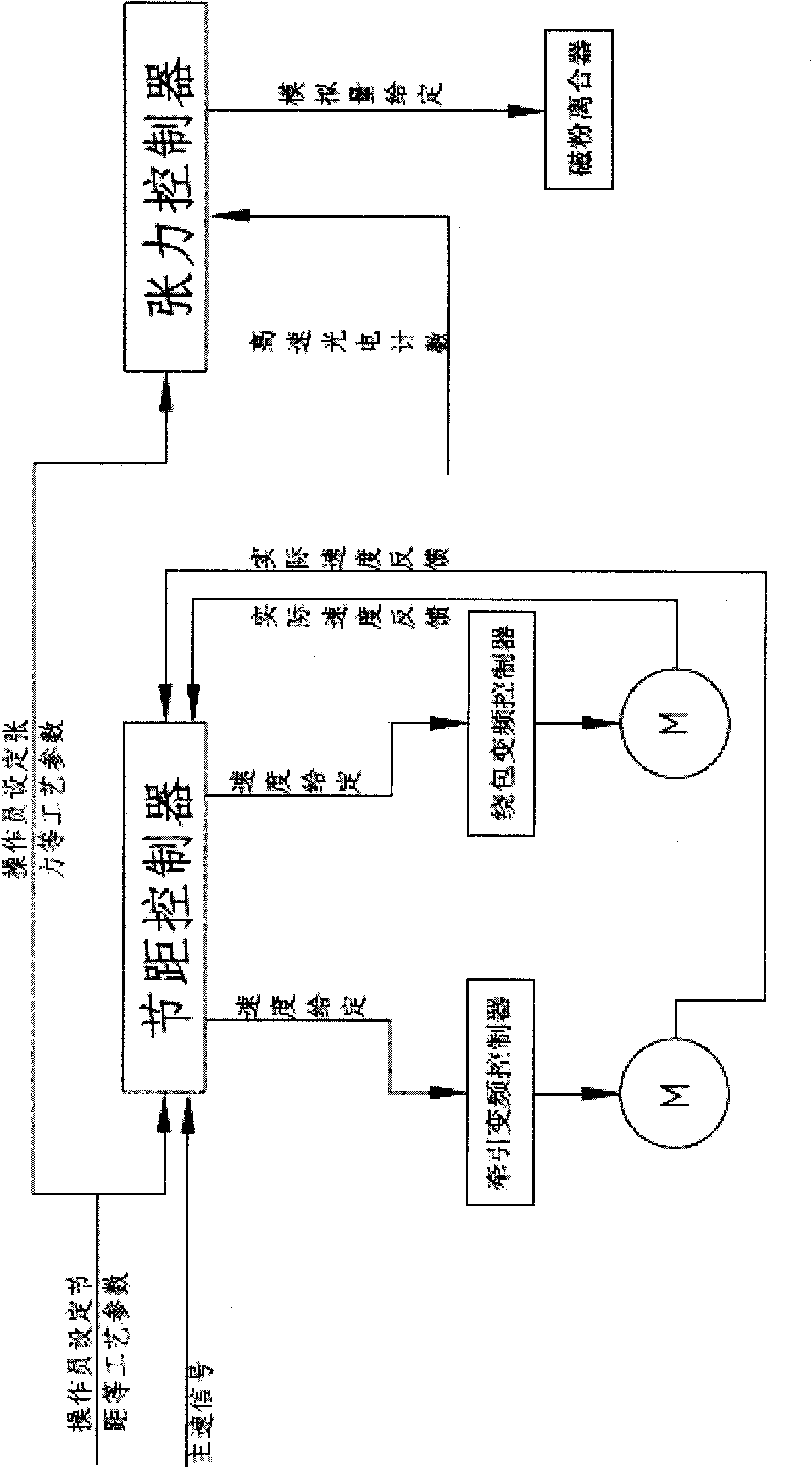

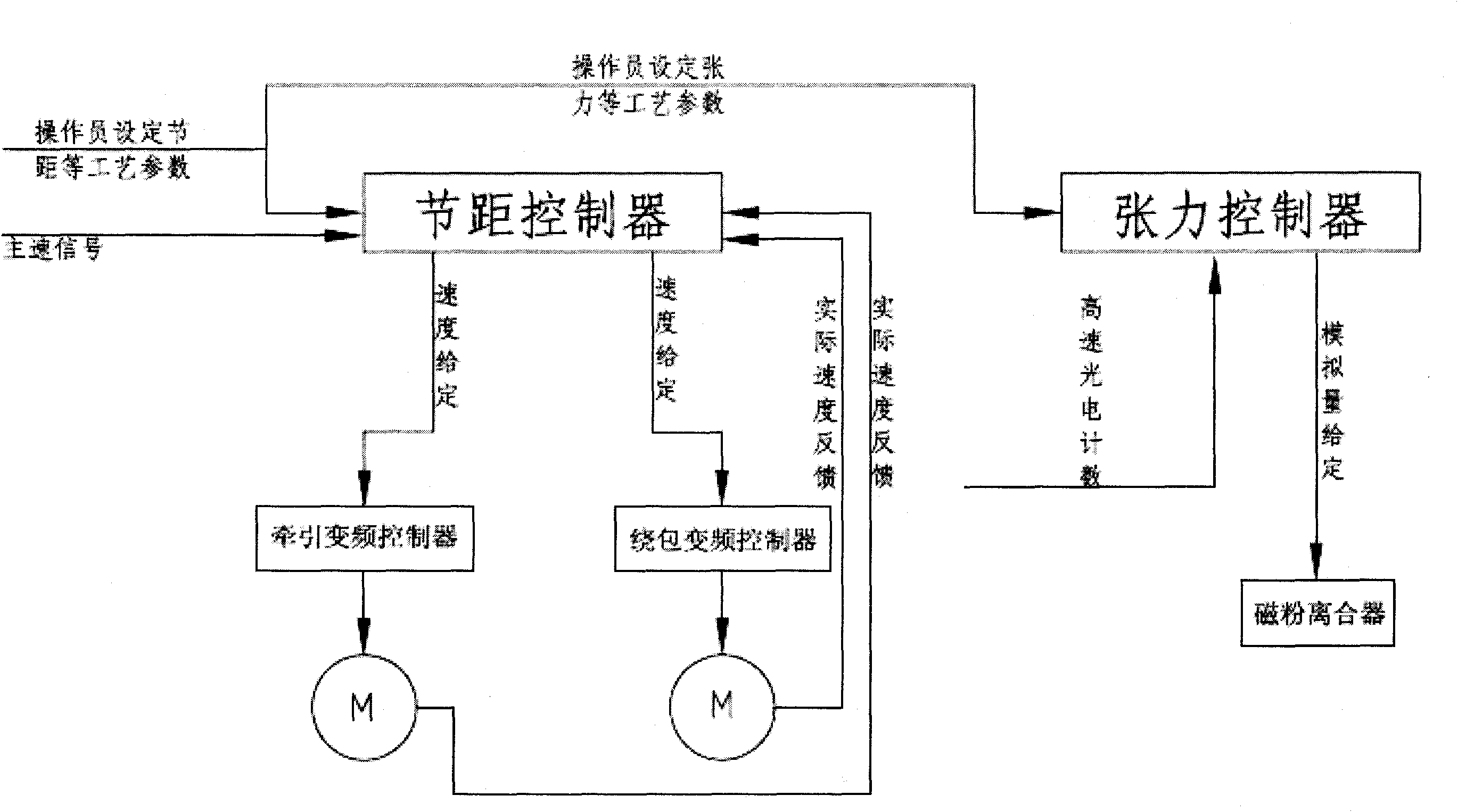

[0019] The present invention is a winding wire wrapping method, as attached figure 1 As shown, the synchronous controller is used to control the traction speed and wrapping speed of the wrapping device in the same proportion, and the PID calculation is performed through the given speed and the actual acquisition speed, and the output speed is tracked in real time, so that the traction and wrapping motors are closed-loop speed controlled, so that Realize accurate pitch control. At the same time, a compensation algorithm is built in the synchronous controller to automatically compensate the acceleration and deceleration of the system and the stop and start operation, so as to realize the precise control of the pitch of the wrappin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com