Spring winding device of lathe

A forming device and winding technology, applied in the field of forming devices for lathe winding springs, can solve the problems of long auxiliary time for cutting steel wires, and achieve the effects of low labor intensity of workers, shortened auxiliary time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

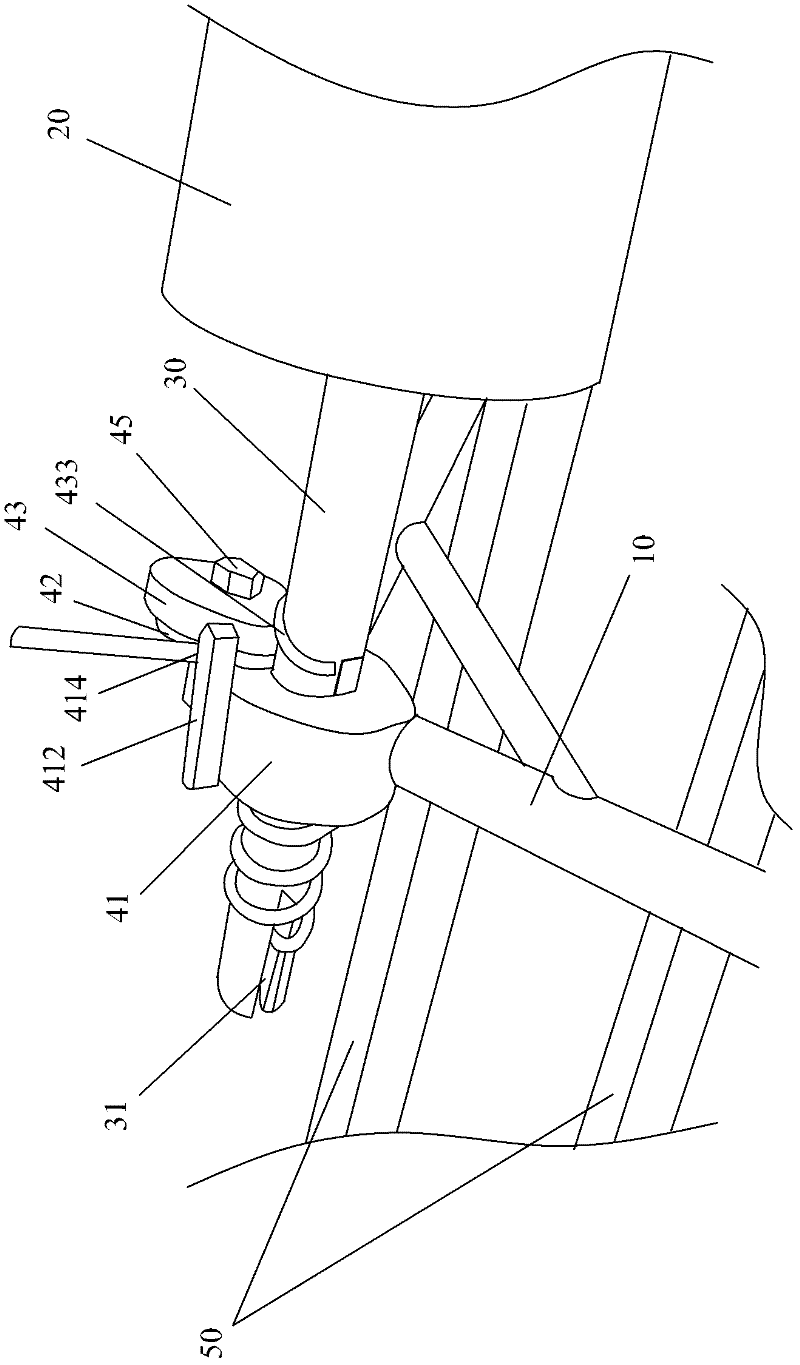

[0025] see Figure 1~3 As shown, the structure of the lathe spring winding forming device of the present invention includes: a frame bar 10, a lathe spindle 20, a mandrel 30 installed on the lathe spindle 20, a forming mechanism 40, and a lathe bed guide rail 50, etc. The mandrel 30 is driven to rotate by the chuck (not shown in the figure) of the lathe spindle 20, and the steel wire is bent and formed into a spring. The forming mechanism 40 is fixed on the frame bar 10 , one end of the mandrel 30 is clamped on the chuck of the lathe spindle 20 , and the other end of the mandrel 30 is matched with the forming mechanism 40 . The end of the mandrel 30 used for spring forming is provided with a slot 31 (the radial opening groove at the extension end of the mandrel 30), the end of the steel wire can be inserted into the slot 31, and the bending of the mandrel 30 , and the remaining steel wire sections are just wound on the mandrel 30 until the end.

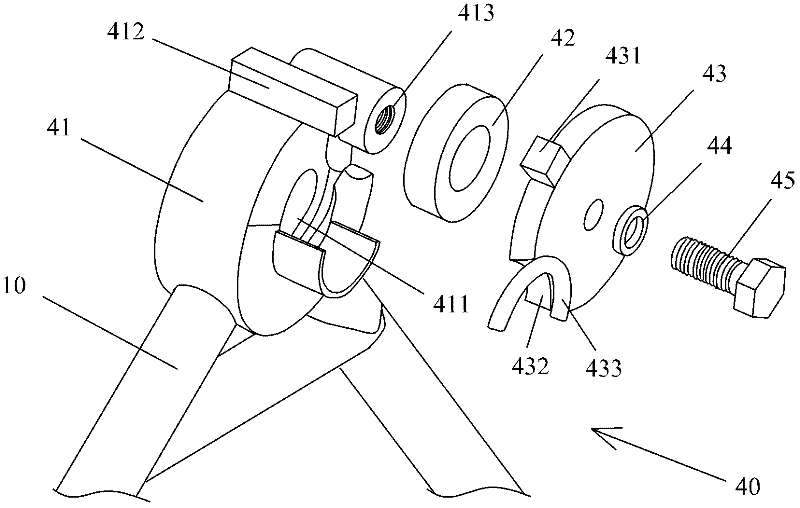

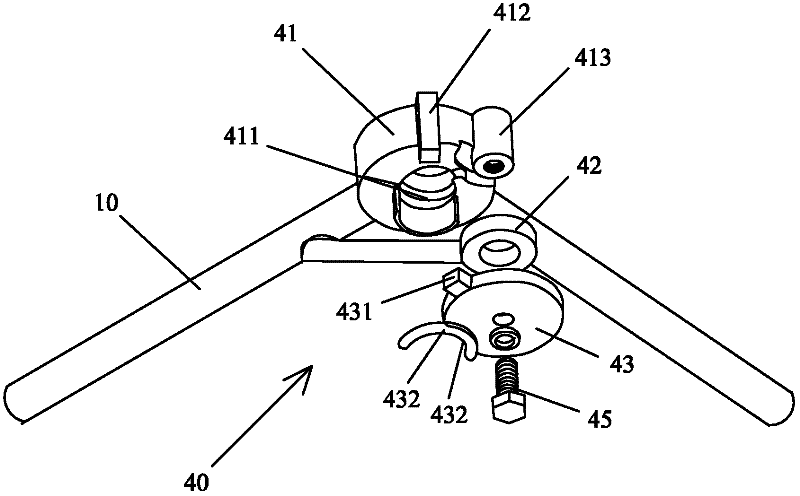

[0026] like figure 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com