Method for measuring gas leakage rate of sintering machine system

A technology of sintering machine system and air leakage rate, which is used in measuring devices, measuring flow/mass flow, liquid/fluid solid measurement, etc., can solve the problems of inaccurate measurement, poor operability, large error, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but is not limited thereto.

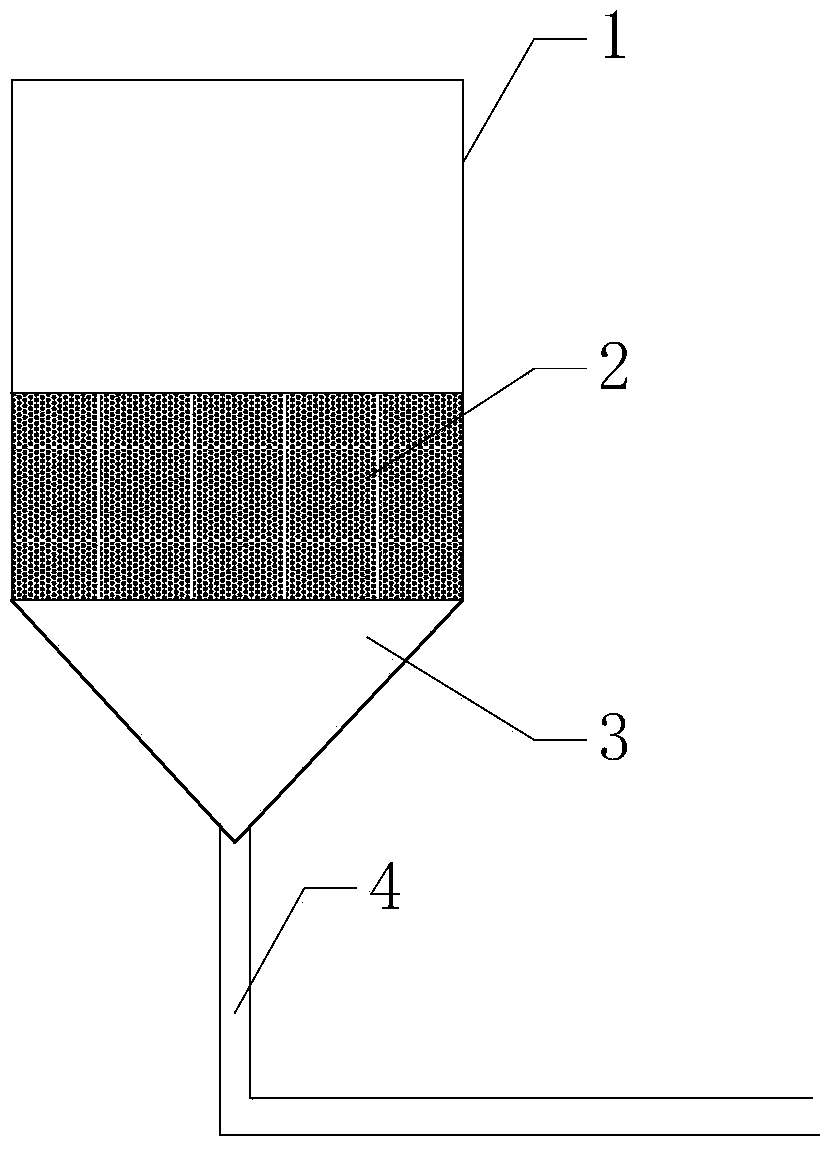

[0032] Such as figure 1 As shown, in the present invention, the sintering machine system includes a sintering machine trolley side plate 1 , a sintering material layer 2 , a wind box 3 and a flue gas duct 4 .

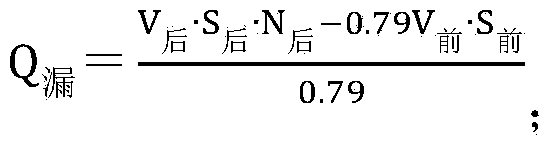

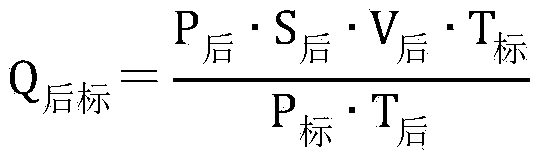

[0033] Firstly, the height of the side plate 1 of the sintering machine trolley upwards is greater than 1 / 2 of the height of the sintering material layer 2, and the thickness of the sintering material layer 2 remains unchanged, so that a material-free space is formed above the sintering material layer 2, and the height of the material-free space is If it is greater than 1 / 2 of the height of the sintering material layer, take measurements at three points along the two edges and the middle of the height on the side plate 1 of the sintering trolley above the sintering material layer 2, and calculate the average value, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com