Image forming characteristics measuring method, image forming characteristics adjusting method, exposure method and apparatus, program and storage medium, and device manufacturing method

a technology of image forming characteristics and measuring methods, applied in the direction of programme control, printers, instruments, etc., can solve the problems of insufficient correction of only the seidel's five aberrations, insufficient accuracy of data obtained, and difficulty for service technicians repairing or adjusting the exposure apparatus or users to obtain such data, etc., to achieve high integration micro-devices, good yield, and good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103]An embodiment of the present invention will be described below with reference to FIGS. 1 to 9B.

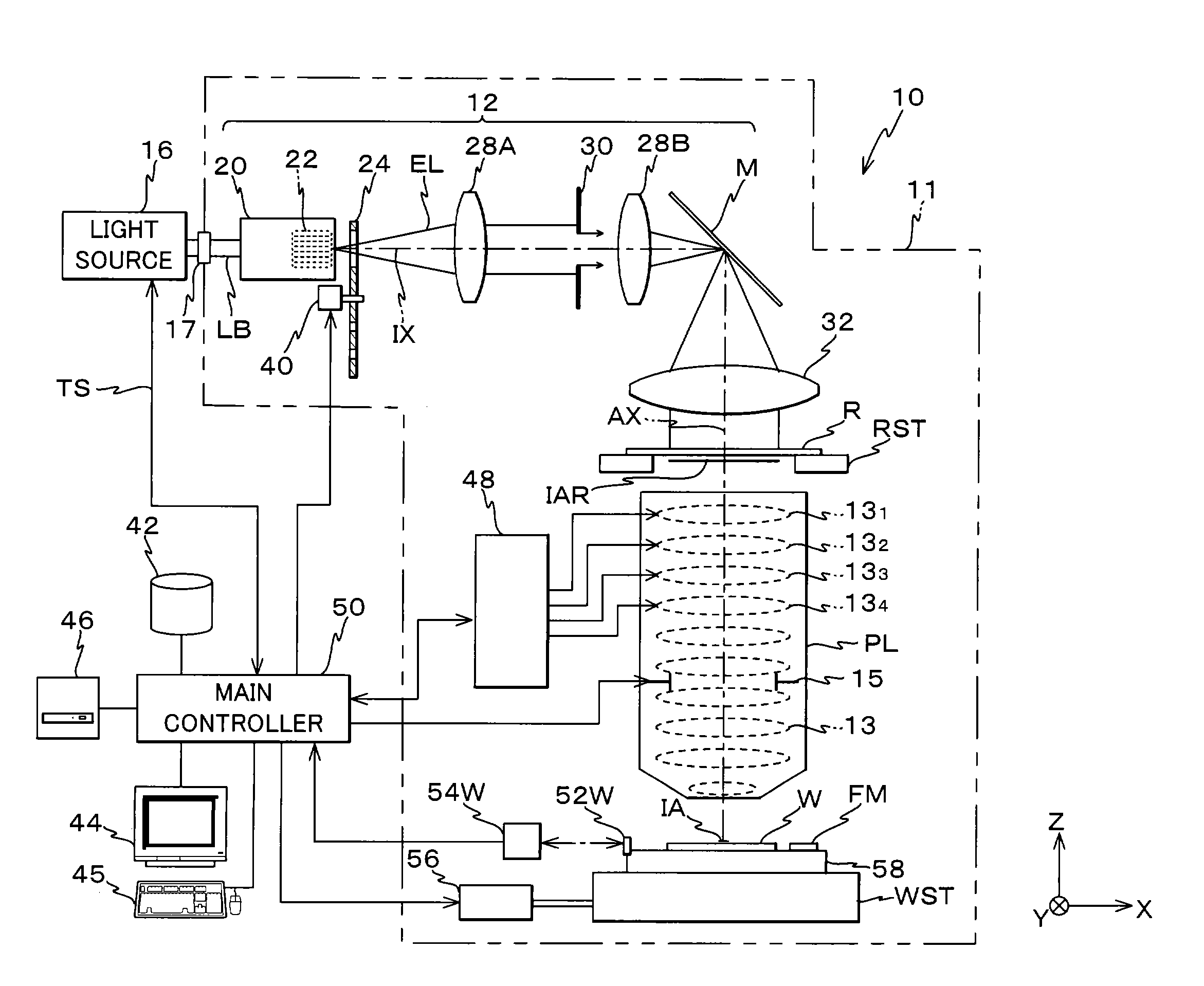

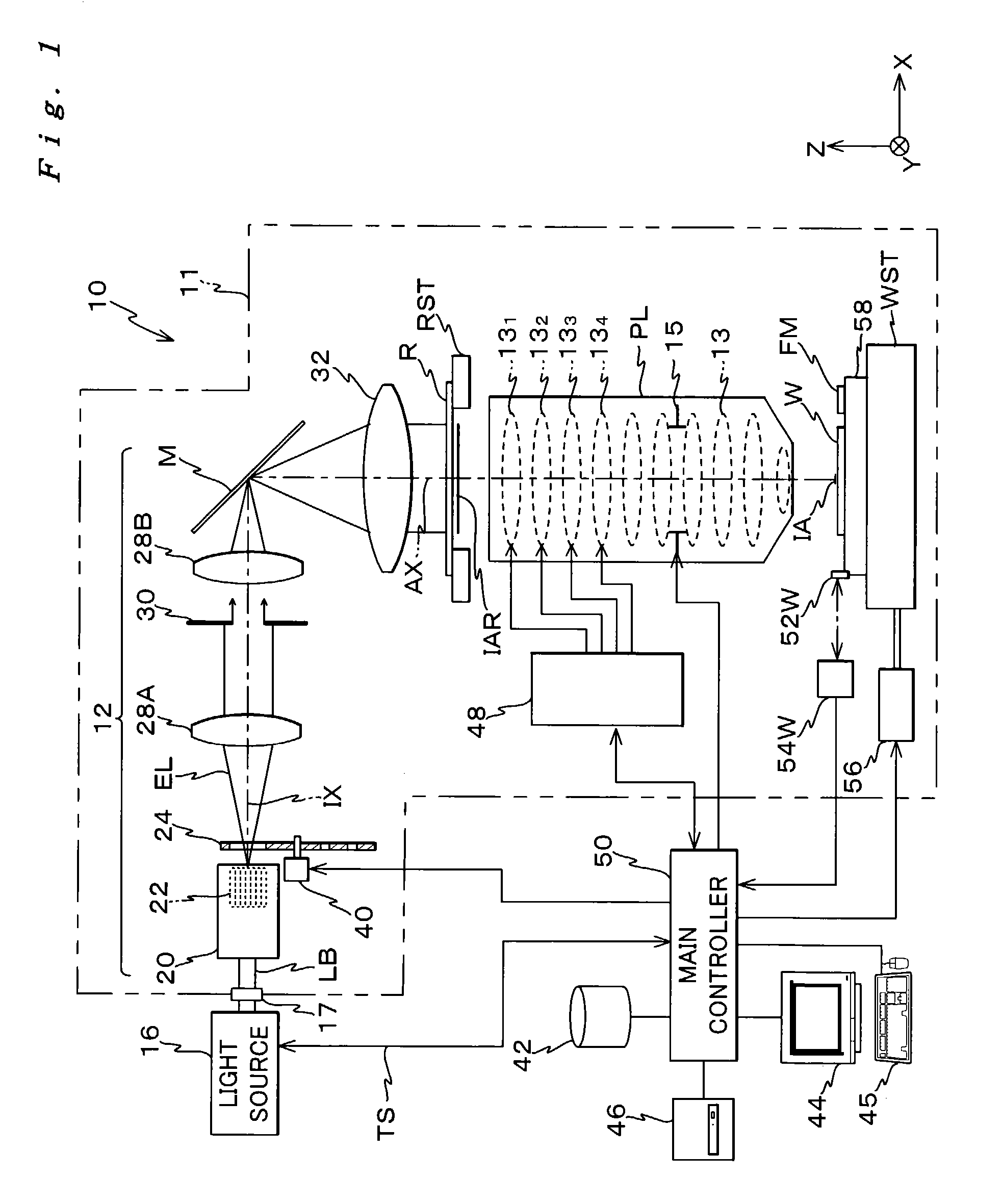

[0104]FIG. 1 shows an entire structure of an exposure apparatus 10 according to an embodiment of the present invention. Exposure apparatus 10 is a reduction projection exposure apparatus based on a step-and-repeat method, or a so-called stepper, which uses a pulse-laser light source as an exposure light source (hereinafter, called a “light source”).

[0105]Exposure apparatus 10 comprises: an illumination system made up of a light source 16 and an illumination optical system 12; a reticle stage RST which serves as a mask stage holding a reticle R serving as a mask, which is illuminated with exposure illumination light EL serving as an energy beam from the illumination system; a projection optical system PL which projects exposure illumination light EL emitted from reticle R onto a wafer W (on the image plane) serving as a substrate; a wafer stage WST serving as a substrate stage on whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com