Method and device for measuring non-aqueous electrolyte battery moisture

A non-aqueous electrolyte, wettability technology, applied in the direction of measuring devices, secondary batteries, secondary battery testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

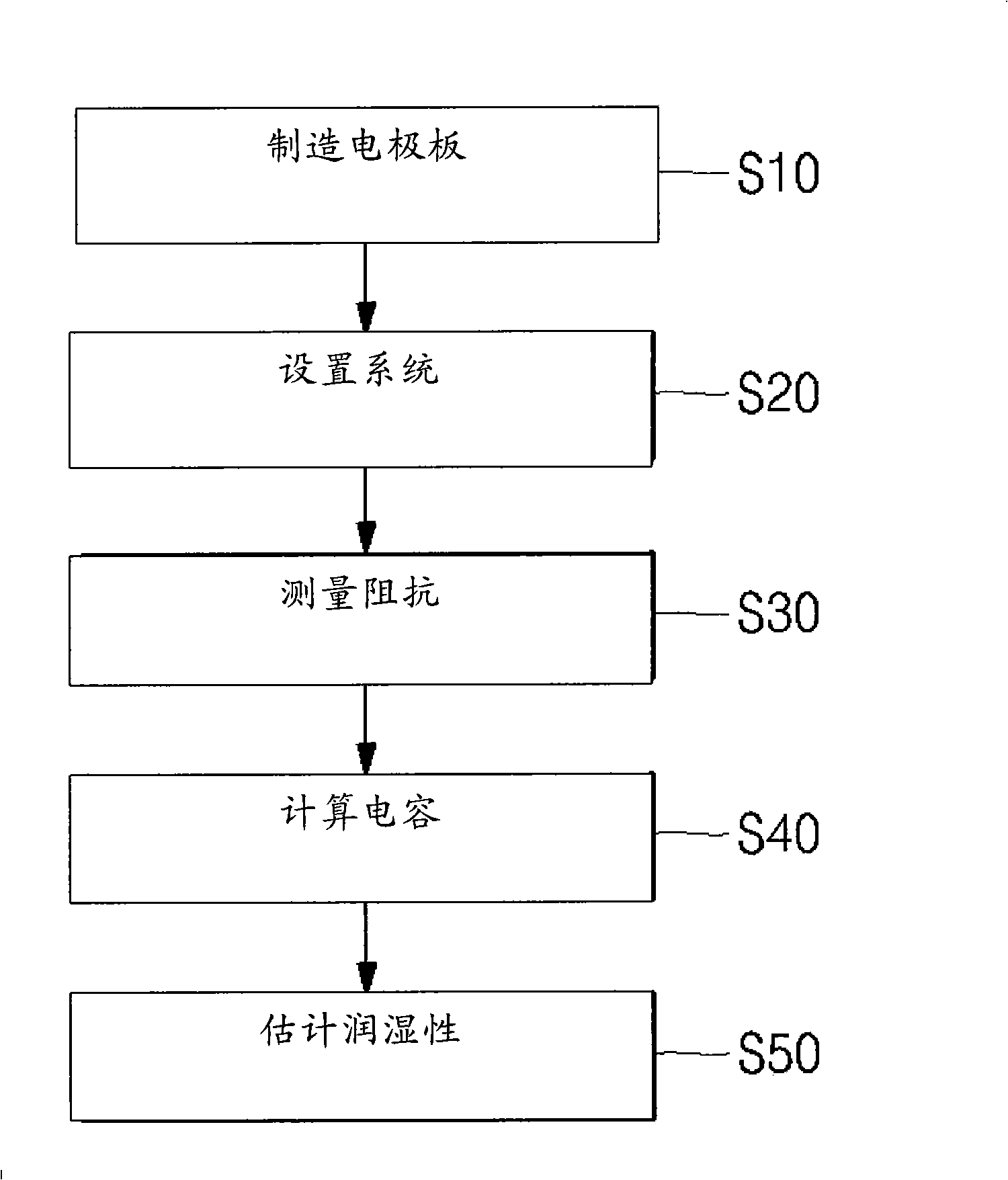

Method used

Image

Examples

Embodiment 1

[0055] The negative plate was fabricated through the following process: artificial graphite as the negative active material, styrene-butadiene rubber (SBR) as the binder, and carboxymethyl The cellulose was mixed to make a slurry, and the mixture was dispersed in water; and the slurry was coated on a copper foil in a thickness of 15 μm and dried, and then rolled using a roll press. The thickness of the mixture of the negative plate is 136μm, and the density of the mixture is 1.625g / cm 3 , making its capacity 2200mAh.

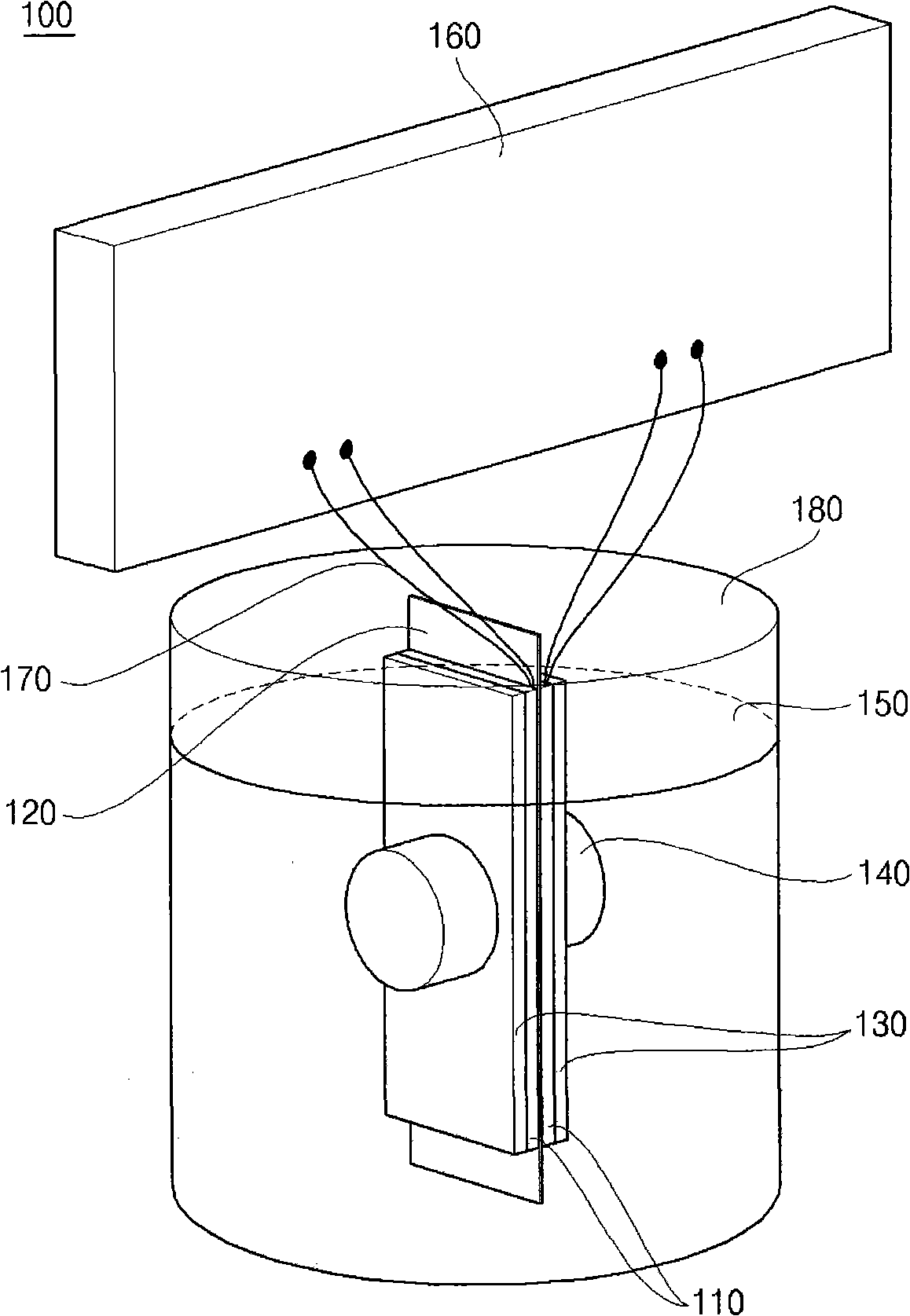

[0056] The standard definition of the negative plate is that the width of the coated part of the negative plate is 25mm (W) × 75mm (L), while the width of the non-coated part of the negative plate is 7mm (W) × 25mm (L) (W: width, L: length). A separator of rayon porous film (thickness: 50 μm) was inserted between two negative electrode plates, and both sides thereof were touched with a glass plate, and fixed by a circular flat magnet. The assembly consisting ...

Embodiment 2

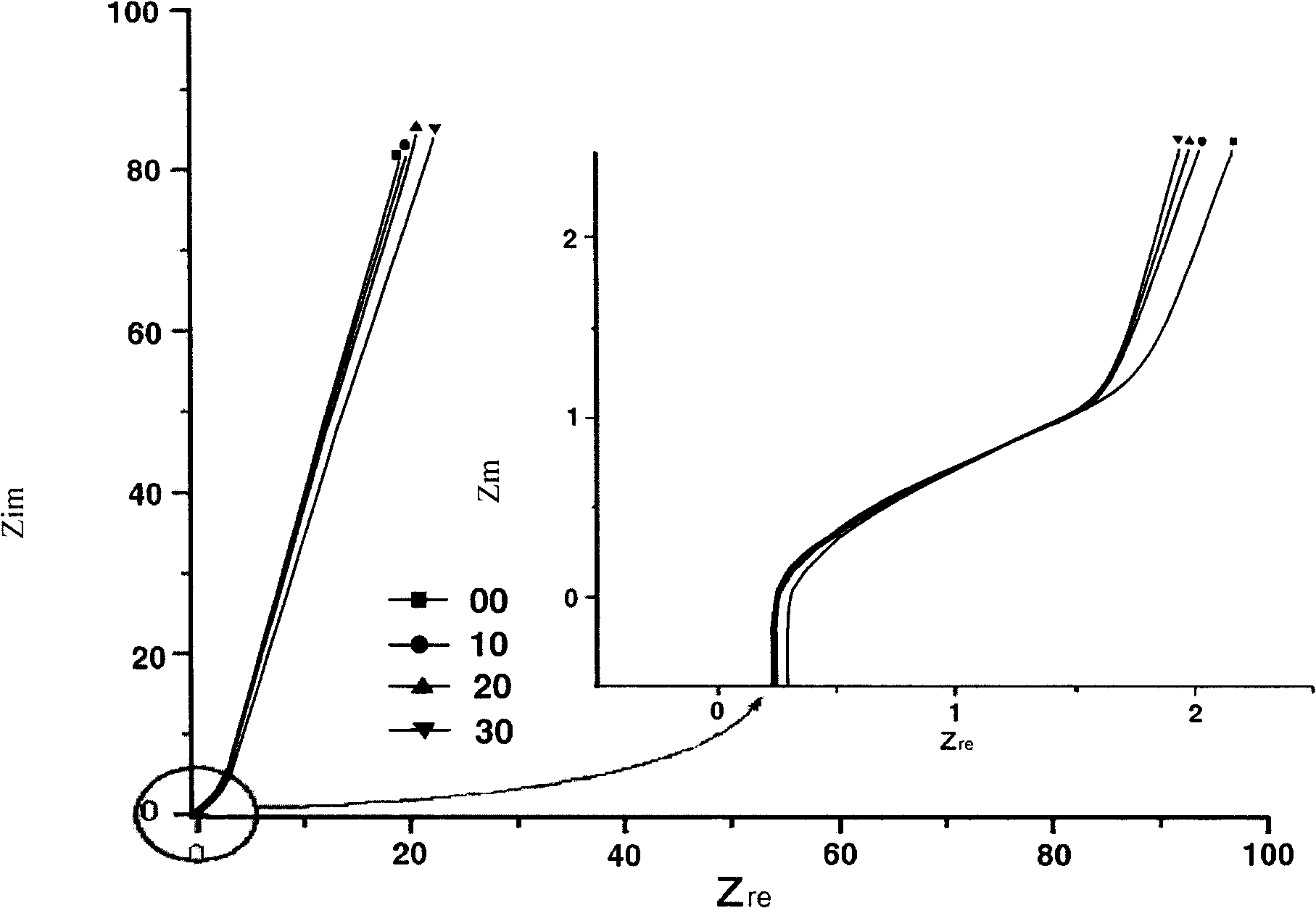

[0058] Example 2 was tested under the same conditions as in Example 1, except that when forming the negative plate, the thickness of the mixture of the negative plate was 126 μm, and the density of the mixture was 1.651 g / cm 3 , and its capacity is 2400mAh. Similarly, Figure 5b Capacitance values corresponding to various frequencies in terms of elapsed time obtained by converting impedance values into capacitance are shown.

[0059]

[0060] refer to Figure 5a and 5b , which shows that Embodiments 1 and 2 have better resolution in the low frequency region of about 100 mHz than in the high frequency region. In addition, it can be appreciated that the capacitance value produced in the case of Example 2 having a high mixture density is lower than that produced in the case of Example 1 having a relatively low mixture density. Thus, the examples demonstrate the fact that the wettability of the electrode plates increases when the density of the mixture is low.

[0061] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com