Expandable graphite-glue powder system thin layer tunnel fire-proof paint

A technology of expanded graphite and fireproof coatings, applied in fireproof coatings, etc., to achieve the effects of short maintenance time, convenient construction, and shortened working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

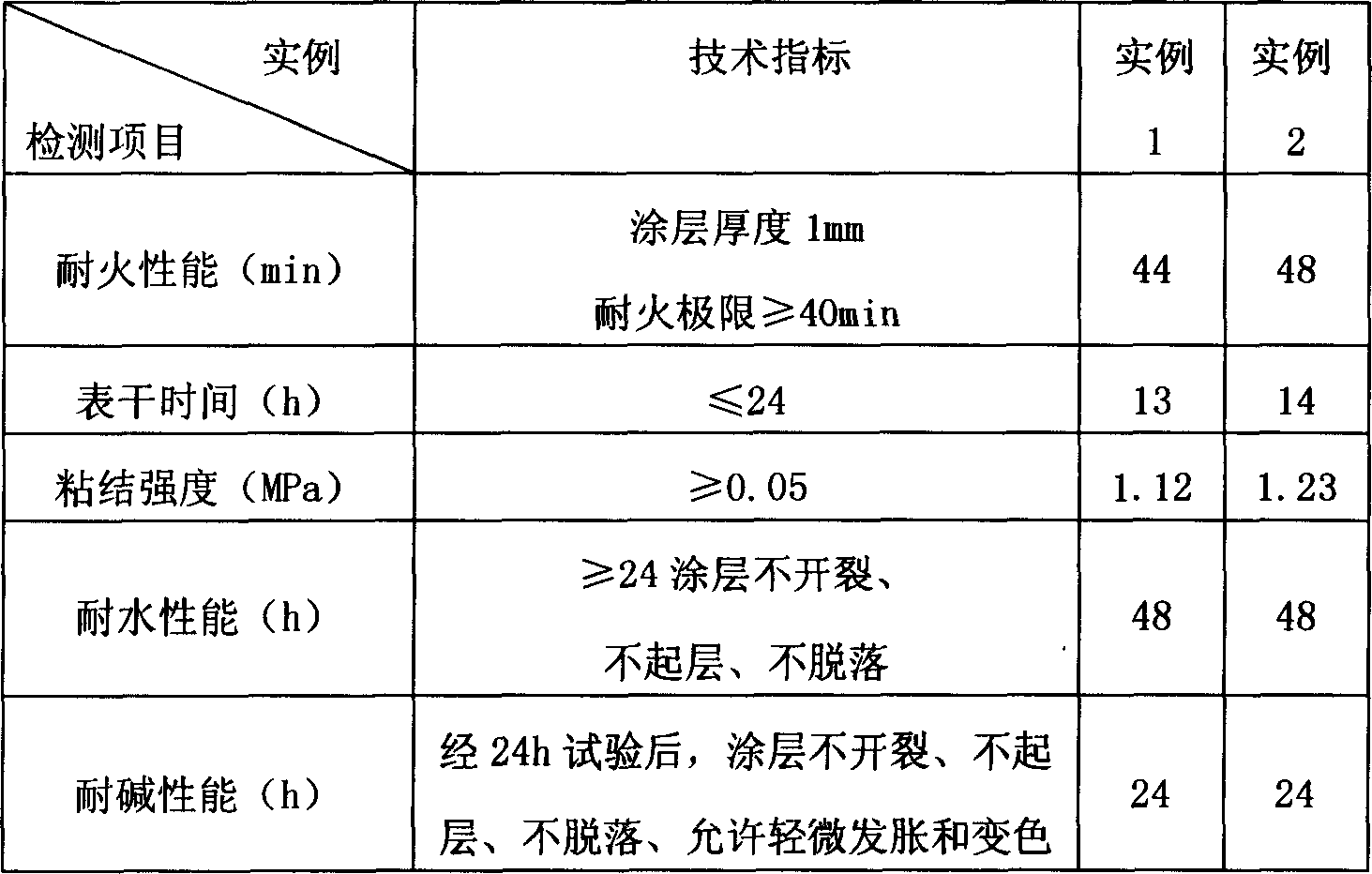

[0018] 50 parts of redispersible latex powder (Vinnapas LL5010), 30 parts of expandable graphite, 5 parts of aluminum hydroxide, 10 parts of magnesium hydroxide, and 5 parts of waterproof powder. After fully mixing the dry ingredients, add 90 parts of water and mix well. The testing methods, items and testing results of the tunnel fireproof coating are shown in Table 1.

example 2

[0020] Redispersible latex powder (Vinnapas LL5010) 50 parts, expandable graphite 40 parts, aluminum hydroxide 5 parts, magnesium hydroxide 15 parts, waterproof powder 10 parts. After fully mixing the dry ingredients, add 90 parts of water and mix well. The testing methods, items and testing results of the tunnel fireproof coating are shown in Table 1.

[0021] Table 1 Technical performance indicators and test results of thin coatings of rubber powder system environmental protection tunnel fire retardant coatings

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com