Very low temperature refrigeration system having a scroll compressor with liquid injection

a refrigeration system and scroll compressor technology, which is applied in the direction of liquid fuel engines, machines/engines, light and heating apparatus, etc., can solve the problems of compressor failure, increase the required floor space of the refrigeration system, and increase the cost of the compressor, so as to reduce the liquid content of the refrigerant, improve the overall system efficiency, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

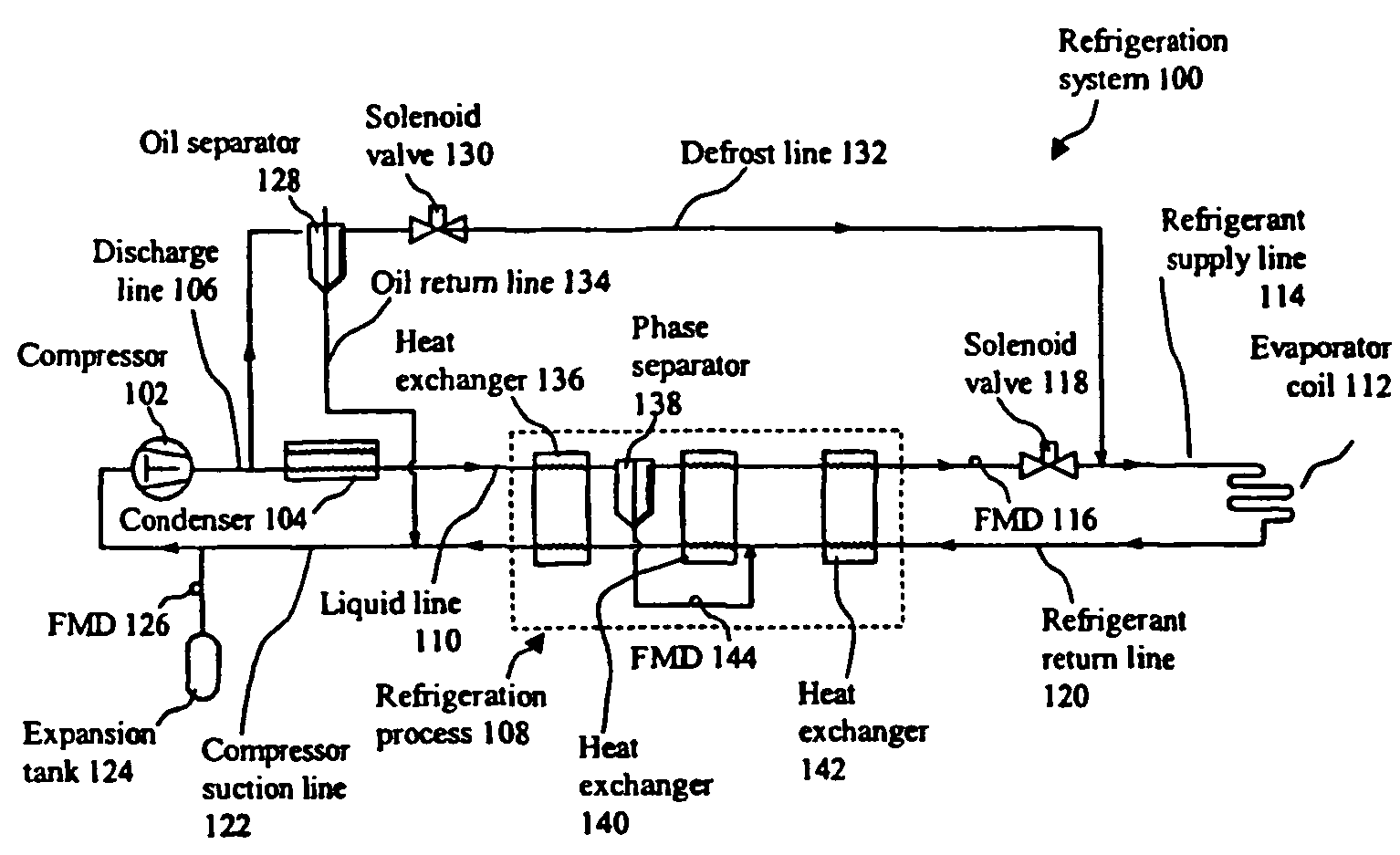

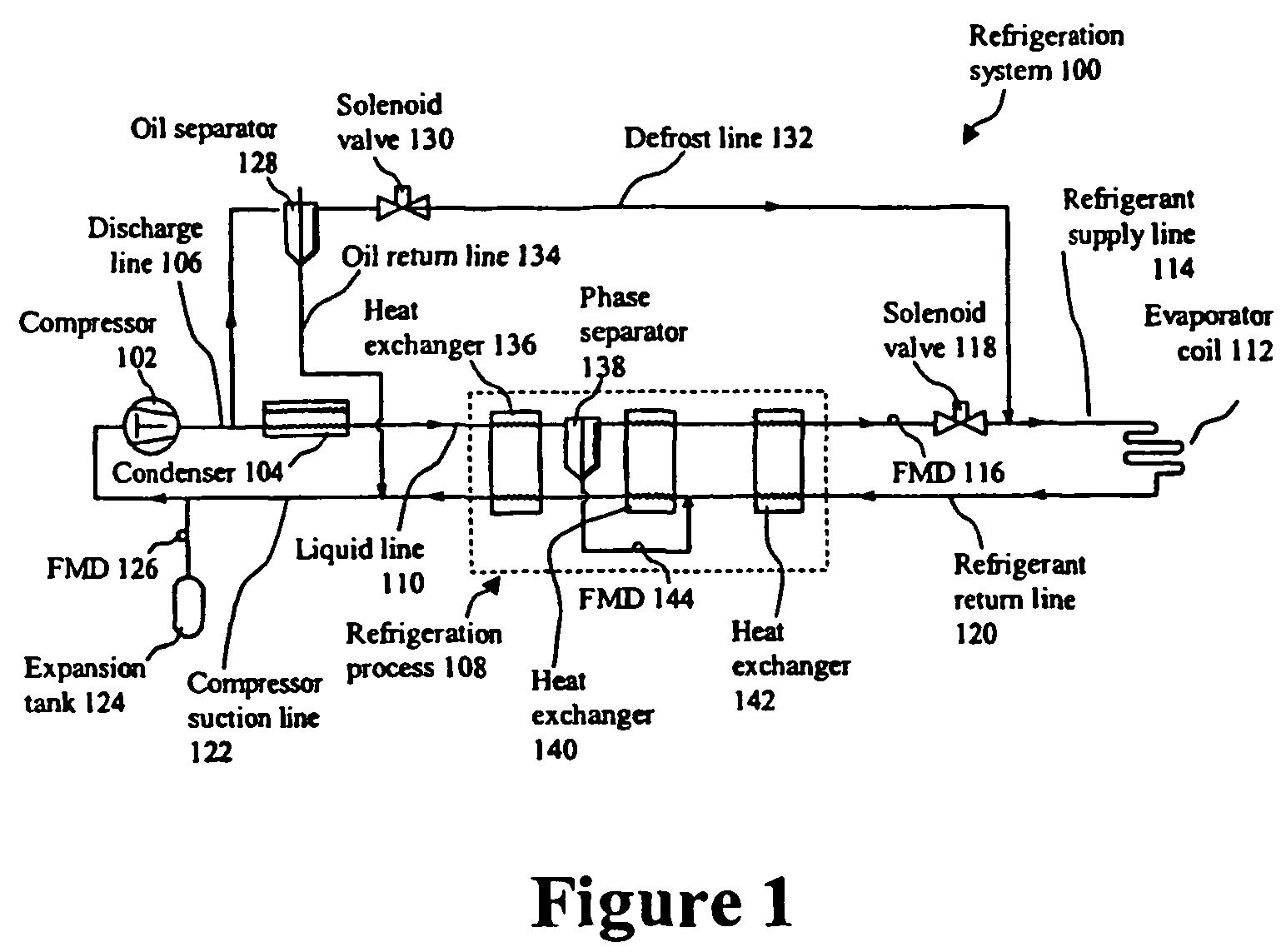

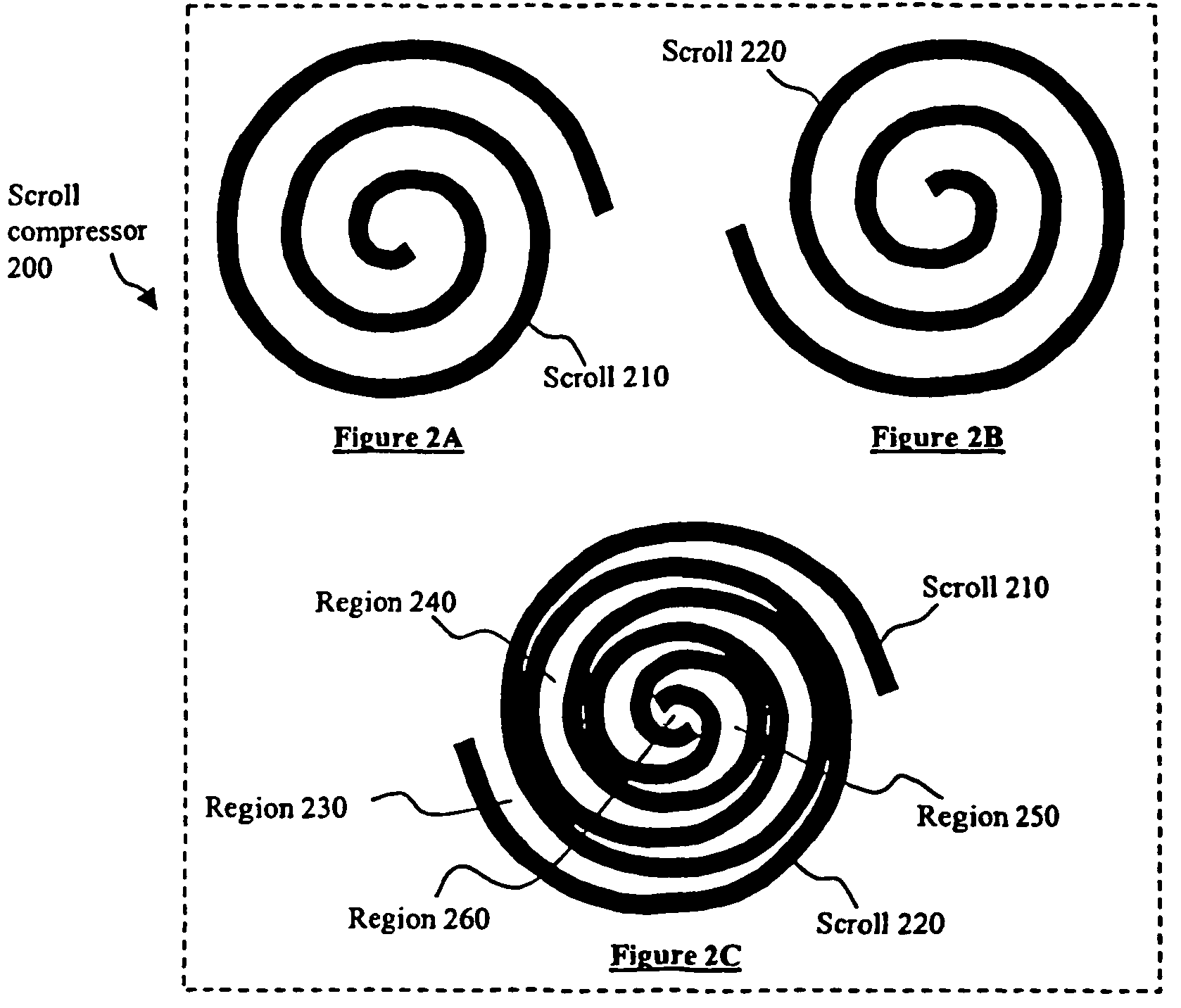

[0073]The present invention is an very low temperature refrigeration system using a commercially manufactured scroll compressor having liquid injection for lowering the discharge temperature and an optional heater for oil sump warming. Management of discharge temperature is achieved by managing the circulation of warm boiling refrigerants and allows for improved overall system efficiency. The use of a scroll compressor provides compact size of the very low temperature refrigeration system as compared with refrigeration systems using conventional semi-hermetic reciprocating compressors. Furthermore, the very low temperature refrigeration system of the present invention uses a commercially manufactured scroll compressor and is suitable for use with optimized refrigerant (MR) blends having warm and low boiling components.

[0074]It uses a commercially manufactured scroll compressor having liquid injection for lowering the discharge temperature and a heater for oil sump warming that inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling points | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| discharge temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com