Scroll Compressors with Different Volume Indexes and Systems and Methods for Same

a compressor and volume index technology, applied in the field of scroll compressors, can solve the problems of fixed efficiency curve, increased complexity, and typically a substantial increase in cost, and achieve the effect of increasing the efficiency of the compressor system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

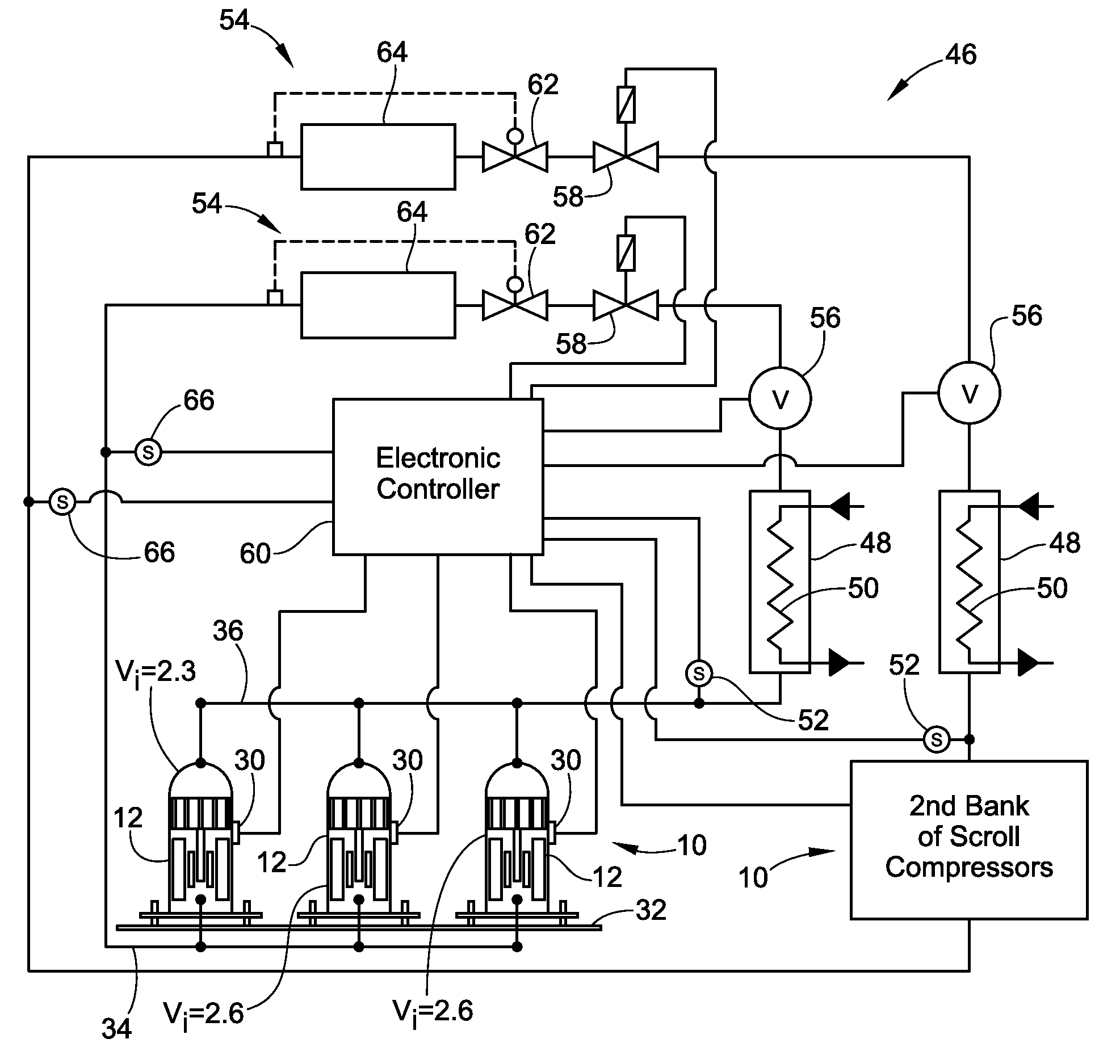

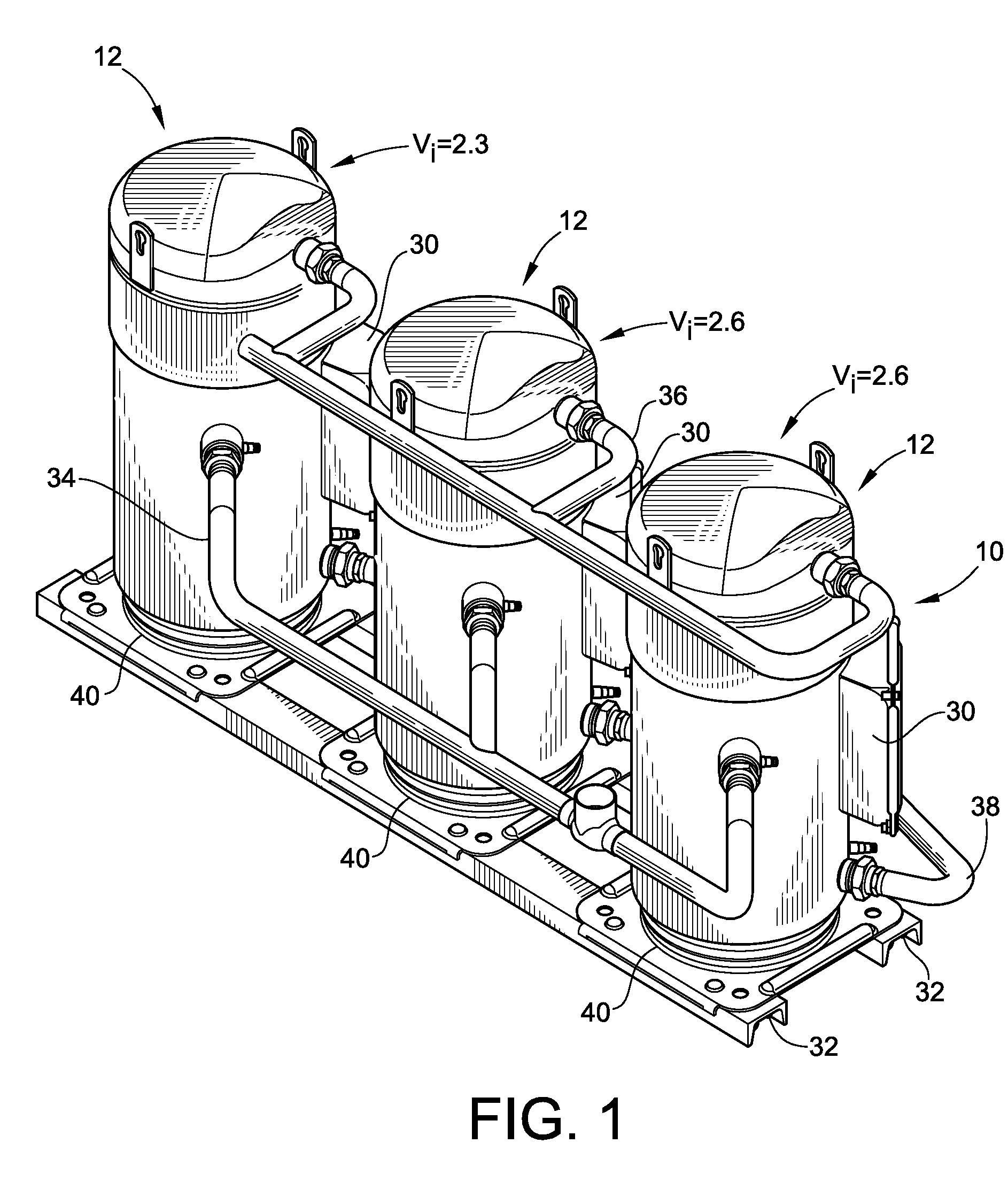

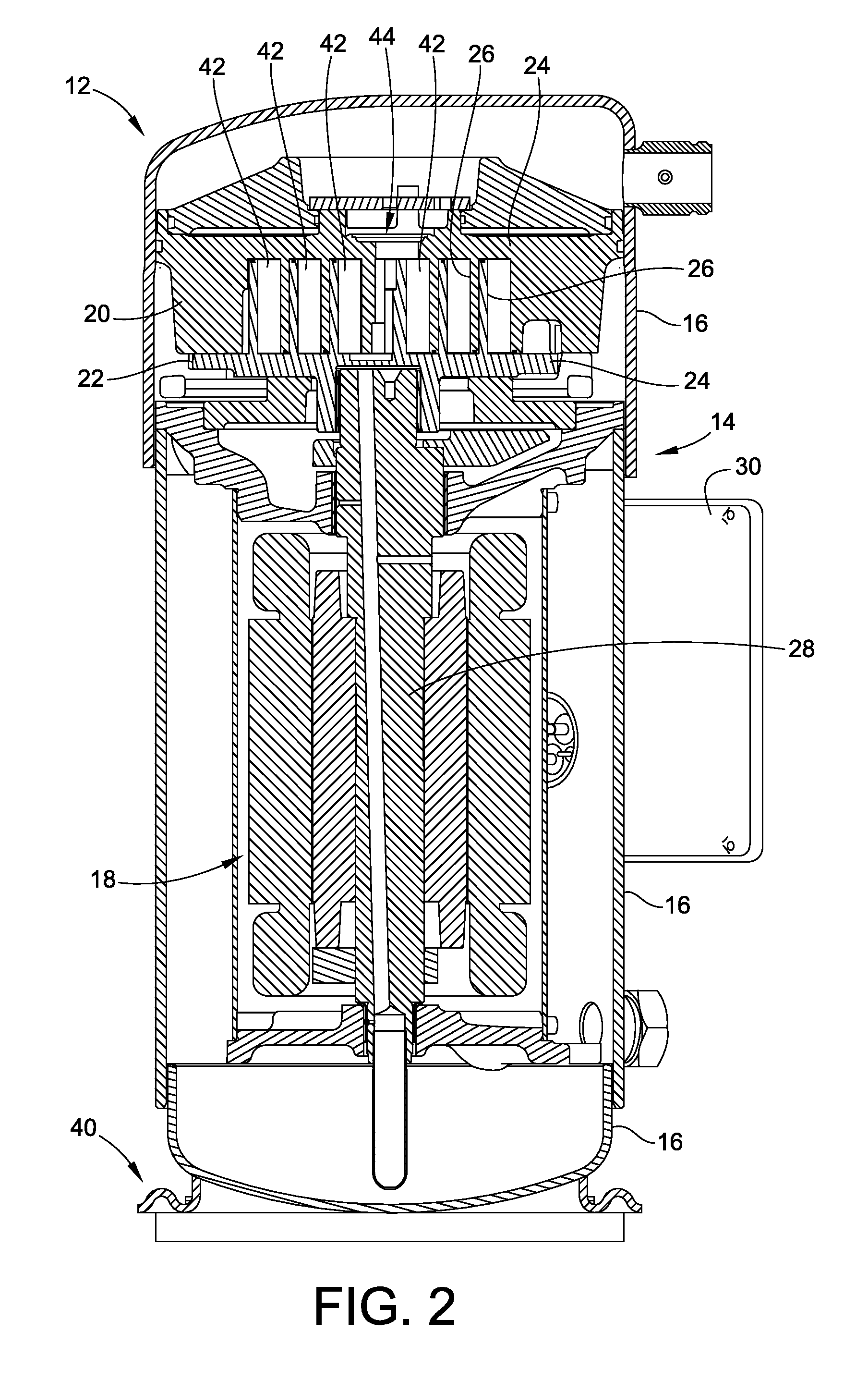

[0028]An embodiment of the present invention has been illustrated in FIG. 1 as at least one bank 10 of compressors of at least two different volume indexes, such as scroll compressors 12, connected in fluid parallel circuit. Each scroll compressor as illustrated in FIG. 1 may be a fixed positive displacement machine that has a non-adjustable built in fixed volume index in that the geometry of scrolls and the compressor chambers that are formed are not adjustable during operation. The bank 10 of scroll compressors may be used in a variety of systems to include air conditioning or chillers, reversible heat pumps, refrigeration units, industrial cooling applications and other such refrigerant circuits (herein cooling and refrigeration and other similar words are used interchangeably and mean the same thing and apply broadly to all such applications indicated).

[0029]Before turning to the details of the parallel circuit bank with different volume indexes, some background about a scroll c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com