Dish washing machine

A technology for dishwashers and inspection doors, which is applied to the washing machine/washing machine for tableware, parts of the washing machine/rinsing machine for tableware, household cleaning devices, etc., can solve the deformation, pressure and torsion resistance of the shell problems such as falling and destroying the strength of the base, to achieve the effect of high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

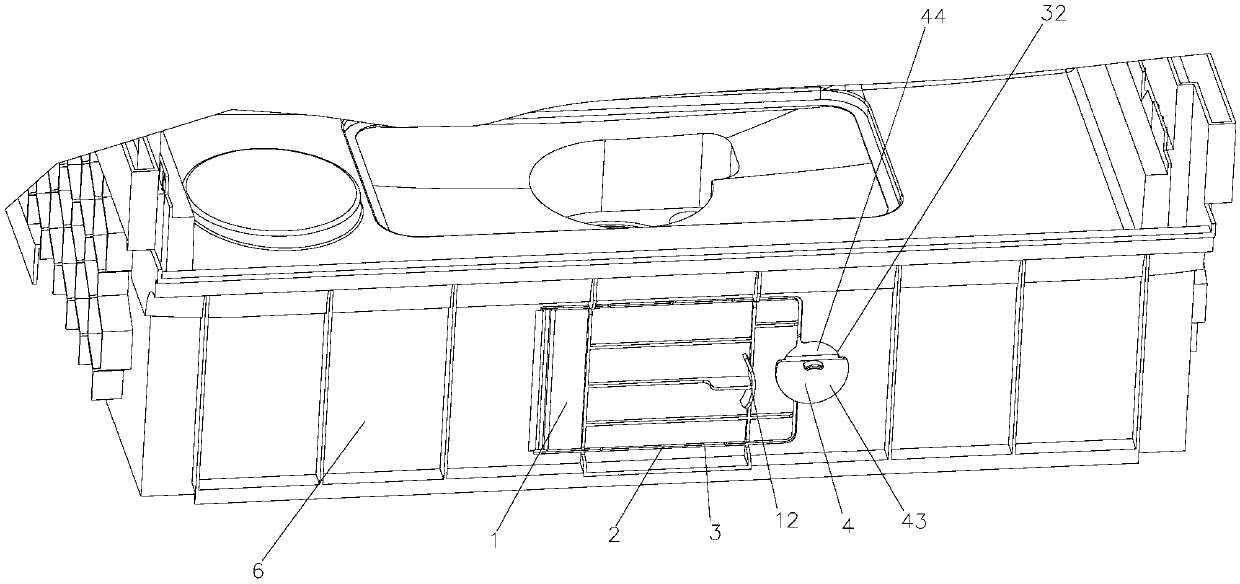

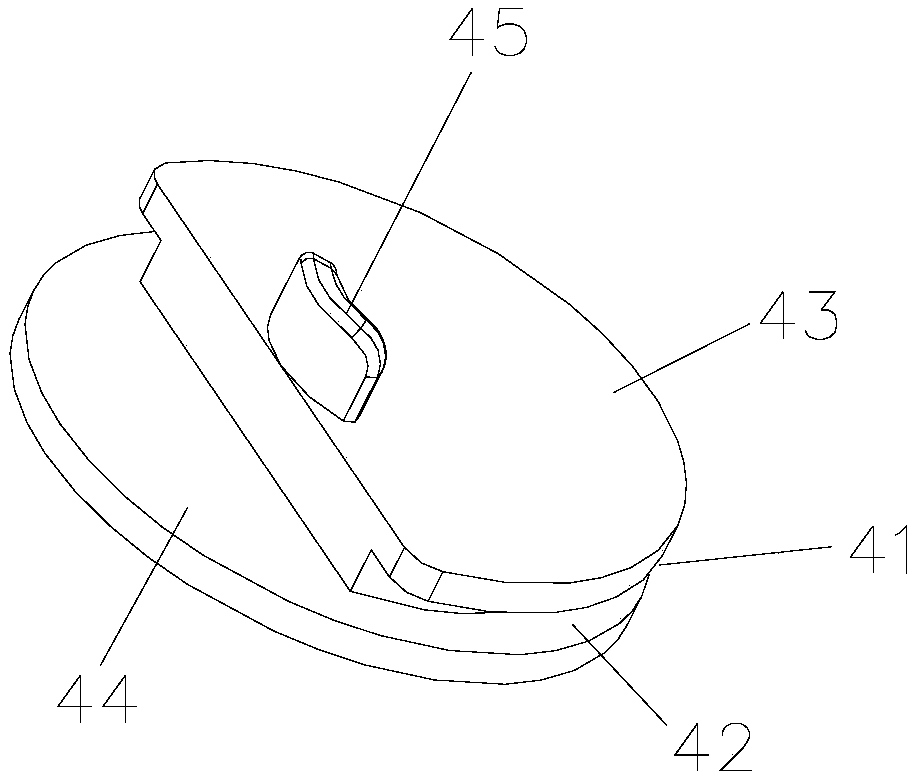

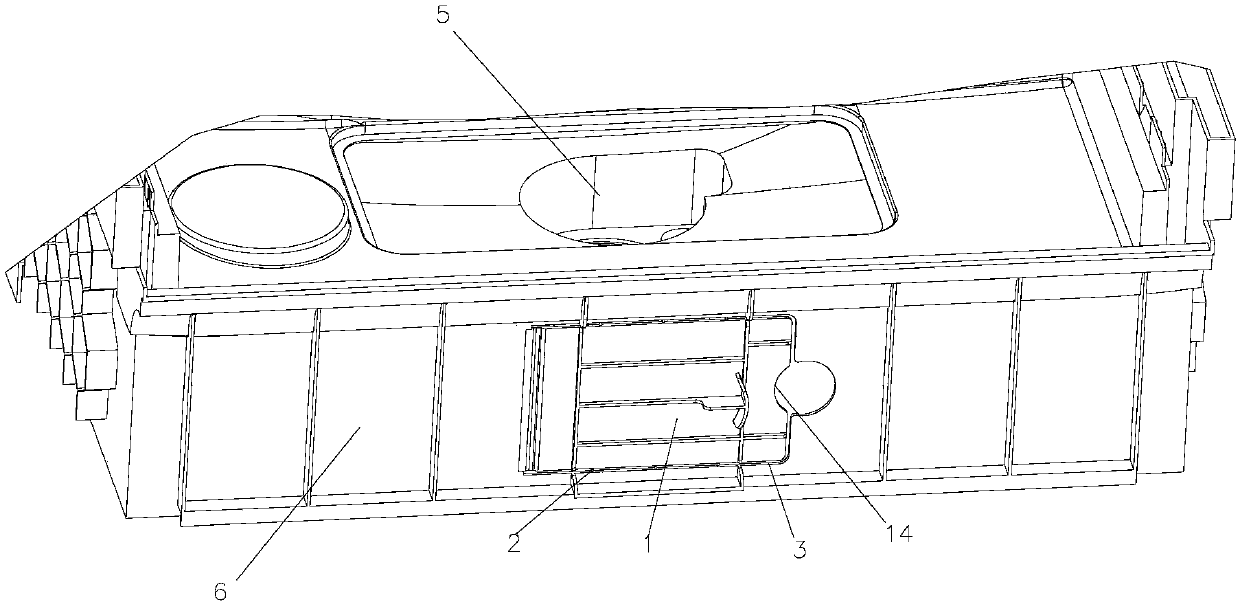

[0047] Such as Figures 1 to 4 As shown, this embodiment discloses a dishwasher. The bottom of the dishwasher in this embodiment is provided with a base, and the housing 6 of the base has a hollow cavity 5, and the drain pump is arranged in the cavity 5, and the drain pump is easily blocked during use. In the past, the dishwasher had to be disassembled and the bottom surface of the dishwasher had to be turned over to complete the maintenance. If the dishwasher was wall-mounted and installed in the cabinet, it would be more troublesome. As shown in the figure, in this embodiment, an inspection port 3 is provided on the housing 6 of the base, and an inspection door 1 matched therewith, and the inspection port 3 and the inspection door 1 are arranged on the side of the base and The corresponding location of the drain pump. Preferably, as figure 1 As shown, in this embodiment, in order to further facilitate the maintenance of the drain pump by the user, the inspection port 3 an...

Embodiment 2

[0061] Such as Figures 1 to 4 As shown, the object of the present invention is to provide a dishwasher. Such as figure 2 As shown, the present invention sets connecting ribs 2 between the inspection door 1 and the inspection port 3 to connect each other. fixed. When the dishwasher needs to be overhauled for the first time, the connecting rib is broken off to release the limiting fixation of the connecting rib to the inspection door.

[0062] According to actual application conditions, the connecting ribs provided on the access door of the dishwasher in the present invention can be set to be connected when the access door is closed, or can be set to be connected when the access door is opened. However, no matter what kind of connection rib arrangement method is used, as long as the initial motion state of the inspection door needs to be changed, the connection rib needs to be disconnected first, and the limit of the inspection door by the connection rib is released before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com