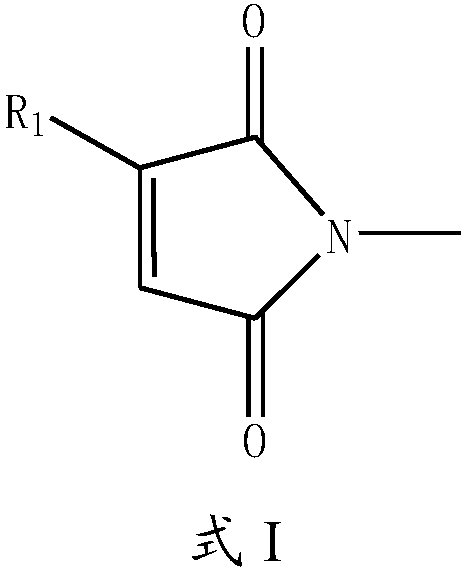

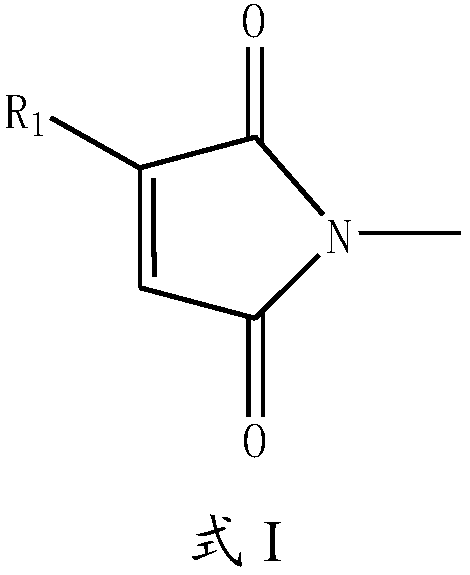

Modified maleimide resin composition and prepreg and laminate prepared therefrom

A technology of maleimide resin and maleimide, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve problems such as seepage, affecting the comprehensive performance of the board, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

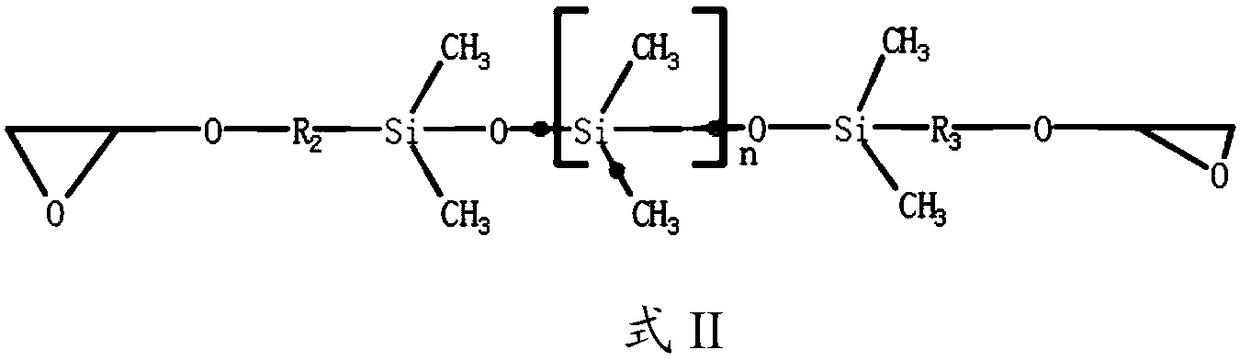

Synthetic example 1

[0139] Add 100g of solvent N,N-dimethylformamide, 60 parts of bis(4-maleimidephenyl)methane, and 20 parts of diaminodiphenylmethane into a 500ml four-necked flask with a reflux device, at 110°C The maleimide-modified aromatic amine was prepared by reacting for 120 minutes, and then 20 parts of a diepoxide-terminated siloxane compound (X-22-163A, manufactured by Shin-Etsu Chemical) was added, and the reaction was continued at 110° C. for 120 minutes to obtain Epoxy siloxane modified maleimide prepolymer Y 1 .

[0140] The double bond in the above-mentioned maleimide compound and the amino equivalent ratio in the aromatic amine compound are 0.83;

[0141] The equivalent ratio of the epoxy group in the epoxy group-terminated silicone oil compound to the amino group in the aromatic amine compound is 0.05.

Synthetic example 2

[0143] In a 500m1 four-necked flask with a reflux device, add 100g of solvent propylene glycol methyl ether, 50 parts of 2,2-bis[4-(4-maleimidephenoxy-phenyl]propane (BMI-80, Japan KI group ), 20 parts of 3,3'-diethyl-4,4'-diaminodiphenylmethane (KARAYARDA-A, manufactured by Nippon Kayaku), reacted at 110°C for 240min to prepare maleimide modified Aromatic amine, then add 30 parts of epoxy-terminated siloxane compound (X-22-163A, manufactured by Shin-Etsu Chemical Co., Ltd.), and continue the reaction at 110°C for 240min to obtain epoxysiloxane-modified maleimide Prepolymer Y 2 .

[0144] The double bond in the above-mentioned maleimide compound and the amino equivalent ratio in the aromatic amine compound are 0.55;

[0145] The equivalent ratio of the epoxy group in the above-mentioned diepoxy group-terminated silicone oil compound to the amino group in the aromatic amine compound is 0.09.

Synthetic example 3

[0147]Add 100 g of solvent propylene glycol methyl ether in the 500 ml four-necked flask with reflux device, 55 parts of biphenyl novolac type polyfunctional bismaleimide resins (MIR-3000, manufactured by Nippon Kayaku), 2,2-bis[4- 25 parts of (4-aminophenoxy)phenyl]propane were reacted at 110°C for 240min to obtain maleimide-modified aromatic amines, and then the diepoxy-terminated siloxane compound (X-22- 163B, manufactured by Shin-Etsu Chemical) 20 parts, continue to react at 110°C for 240min to obtain epoxysiloxane-modified maleimide prepolymer Y 3 .

[0148] The double bond in the above-mentioned maleimide compound and the amino equivalent ratio in the aromatic amine compound are 1.64;

[0149] The equivalent ratio of the epoxy group in the epoxy group-terminated silicone oil compound to the amino group in the aromatic amine compound is 0.09.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com