Method for measuring magnetism of surface nanostructure

A measurement method and nanostructure technology, applied in the direction of measurement devices, polarization-influenced characteristics, instruments, etc., can solve the problems of complex devices, high prices, and the imaging effect is easily limited by optical components, so as to avoid through-hole damage and save Cost, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

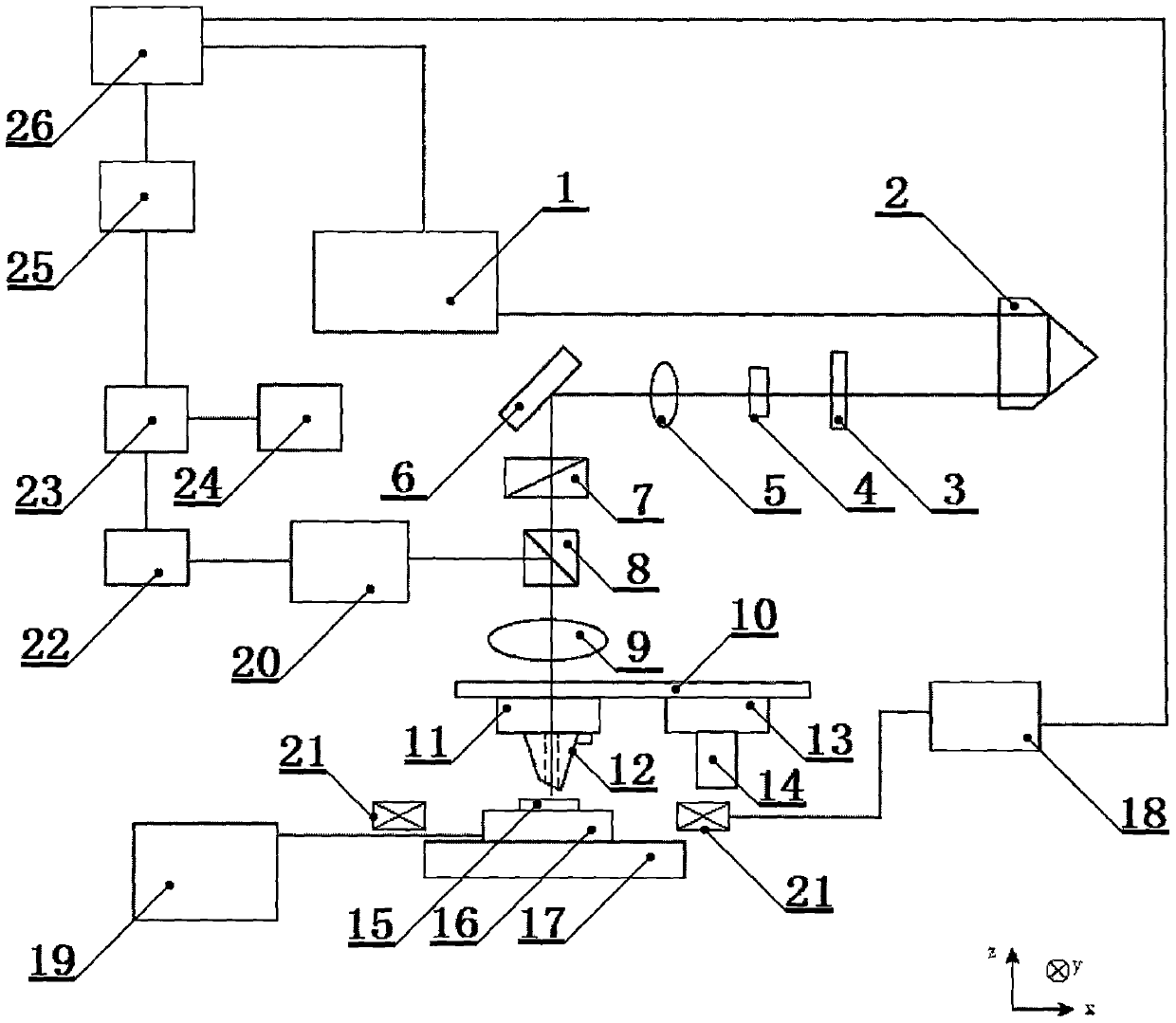

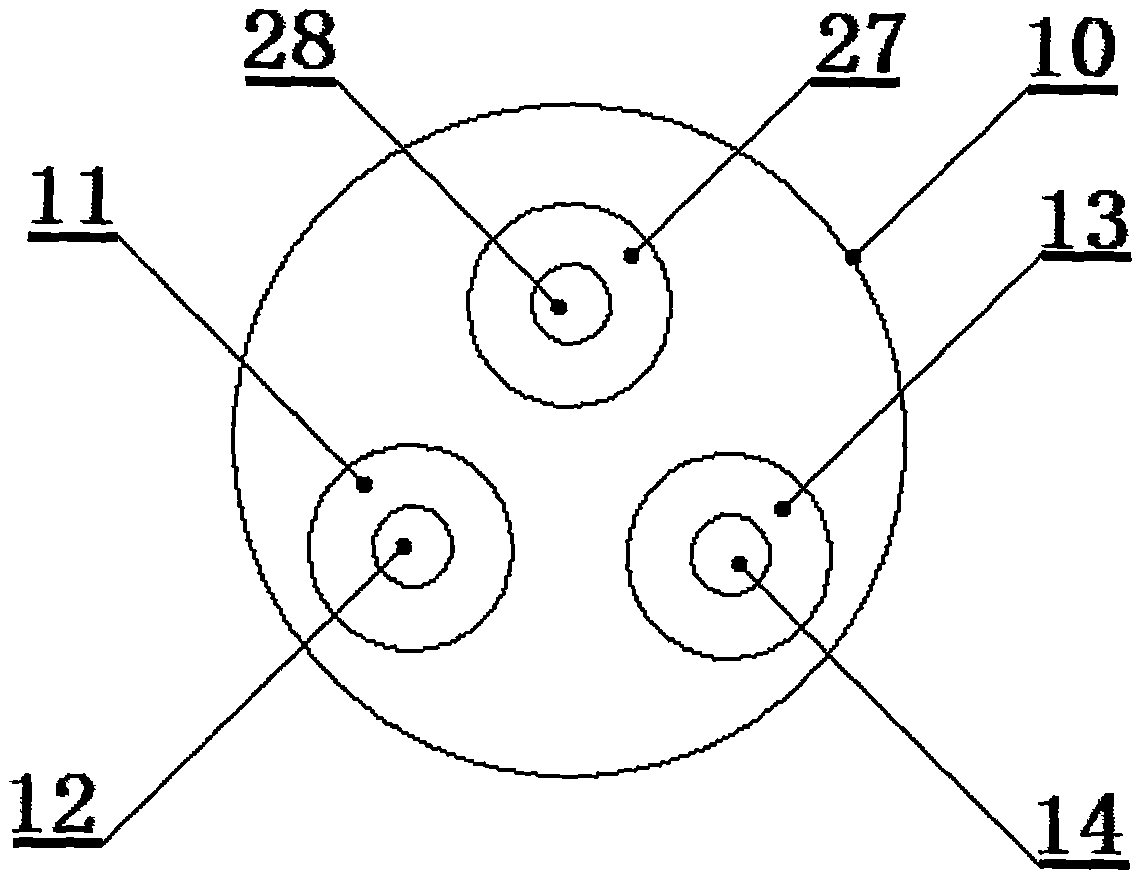

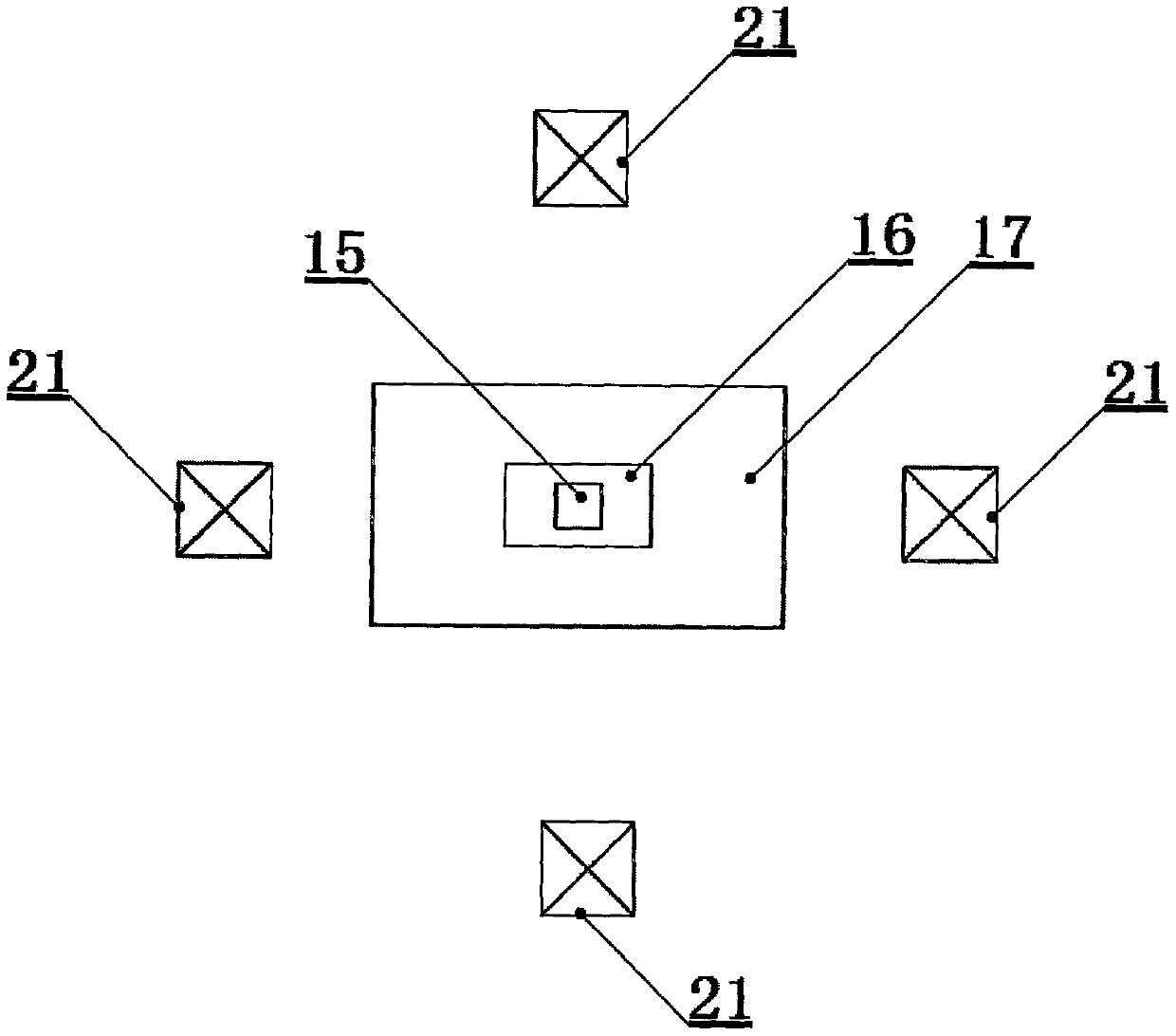

[0026] Such as figure 1 It is a schematic diagram of the present invention, the lower right corner has an xyz three-dimensional direction mark, xyz is a spatial rectangular coordinate system, and the xy plane is a horizontal plane. The laser beam emitted by the laser 1 passes through the delay device 2, 1 / 4 wave plate 3, concave lens 4, Convex lens I 5, flat mirror 6, polarizer 7, beam splitter 8, convex lens II 9, lens stand 10, atomic force microscope I 11, probe I 12, thereby forming the incident light path, the laser beam irradiated on the sample 15 surface generated The reflected light sequentially passes through the probe I12, the atomic force microscope I11, the lens stage 10, the convex lens II9, and the beam splitter 8, thereby forming a reflected light path. The reflected light is deflected to the detector 20 by the beam splitter 8, and the probe There is a through hole in the needle I 12, the probe II 28 is a contact-type atomic force microscope probe, the probe I 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com