Full-automatic square tube cutting machine

A cutting and fully automatic technology, which is applied in metal processing, metal processing equipment, pipe shearing devices, etc., can solve the problems that the grinding wheel cutting machine is easy to produce burrs, debris and sparks, which are easy to cause danger, and the cutting stability is poor. It is not easy to achieve Significant deformation, improved cutting quality, and reduced cutting power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

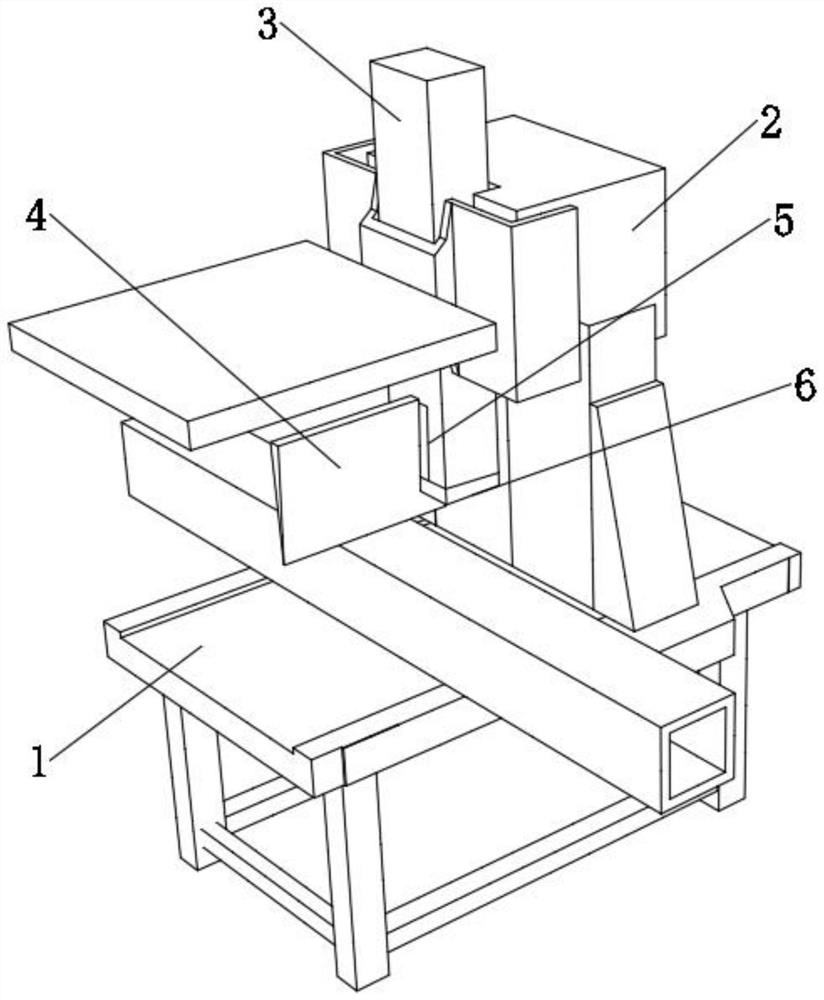

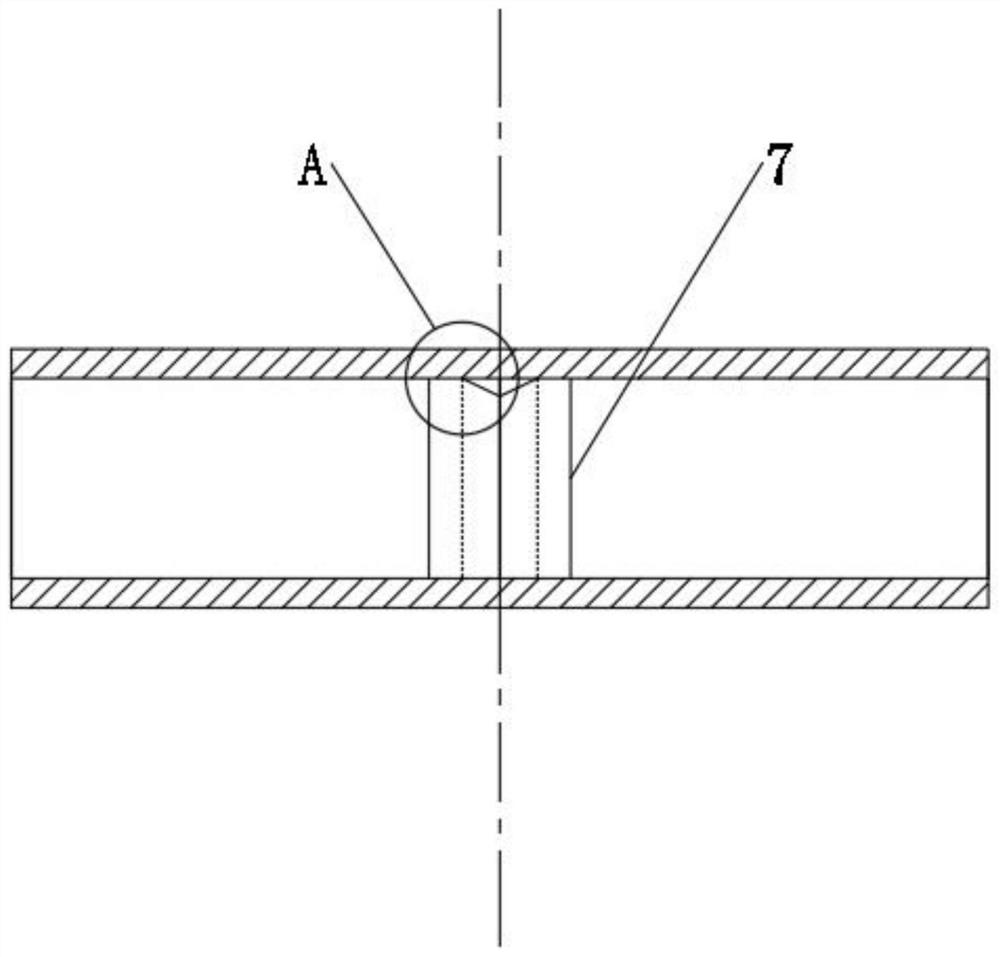

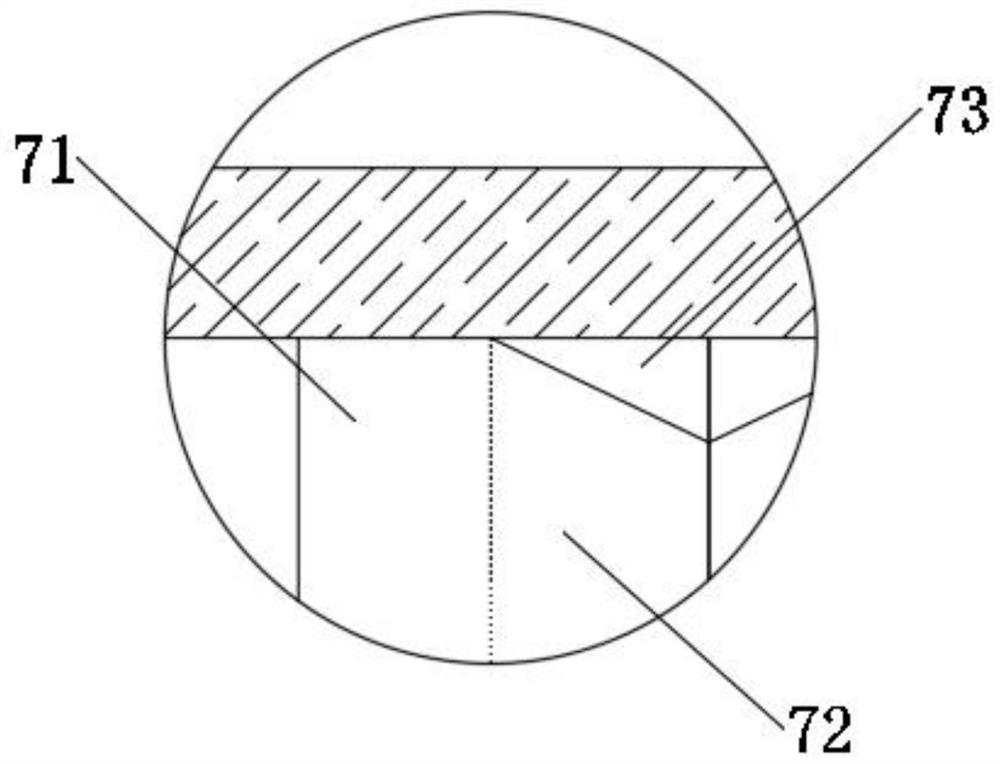

[0042] see Figure 1-3 , a fully automatic cutting machine for square tubes, comprising a cutting table 1, a mounting frame 2 is installed on the upper end of the cutting table 1, a lifting table 3 is installed on the mounting frame 2, a cutting blade 4 is installed on the driving end of the lifting table 3, and the cutting table 1, a square tube positioned at the lower side of the cutting blade 4 is also placed on the upper end, a heater 5 and an electromagnet 6 are also installed on the lift table 3, a pair of matching heat deformation and shaping blocks 7 are slidably connected in the square tube, and a pair of heat The deformation-setting blocks 7 are symmetrically distributed, and the heat-deformation-setting blocks 7 include an outer base portion 71, an inner support portion 72 and a heat guide portion 73, and the inner support portion 72 is connected to the outer end of the outer base portion 71, and the inner support portion 72 is located at a pair of outer bases. One ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com