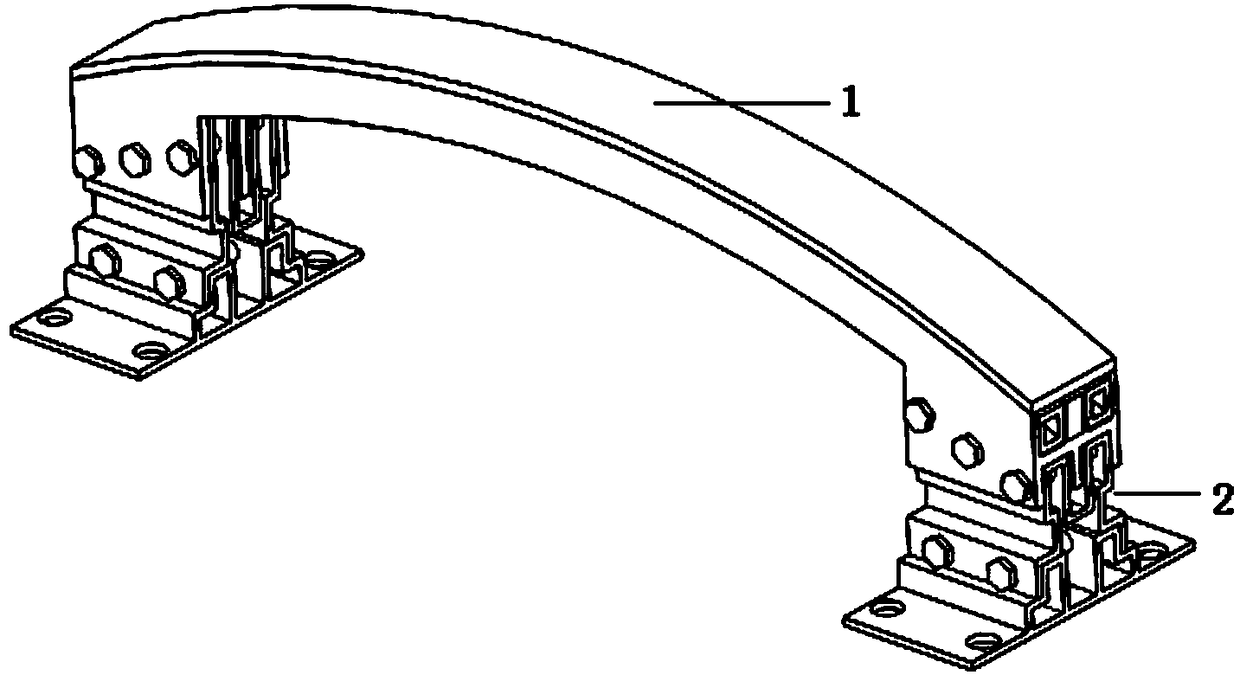

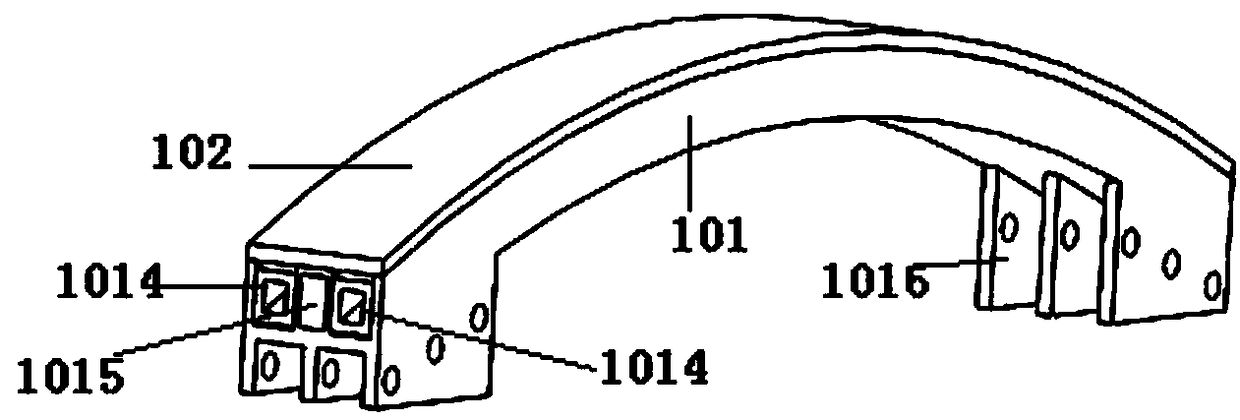

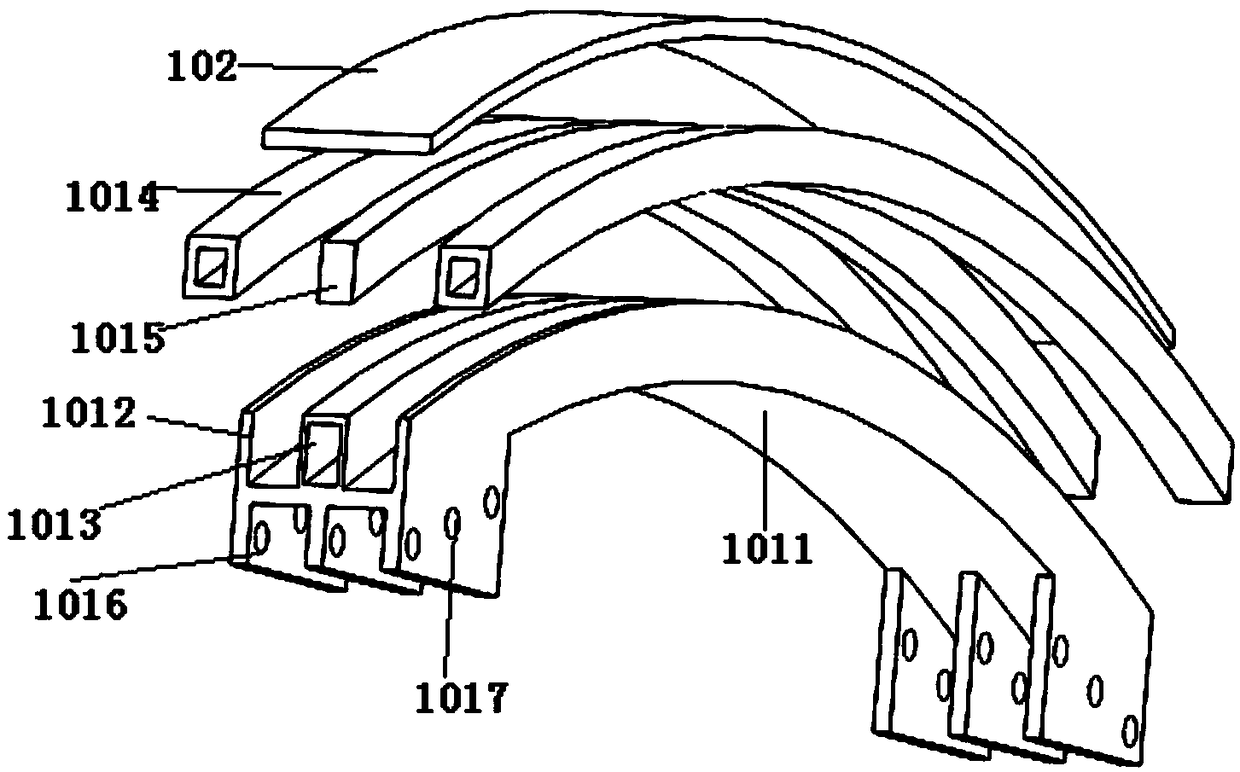

Automobile anti-collision protection mechanism and anti-collision material thereof

A protection mechanism and anti-collision technology, applied in the direction of bumpers, etc., can solve the problems of non-reuse, easy deformation of anti-collision devices, etc., to achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0034] The anti-collision material used by the automobile anti-collision protection mechanism is prepared by the following process:

[0035] (1) Add 10kg of discarded ferrous materials into an intermediate frequency induction furnace and smelt until the ferrous materials are melted into molten iron, then add 10g of boron oxide, smelt for 10-20min, then add 60g of graphite for smelting, and smelt for 50-70min;

[0036] (2) Then add 260g of silicon carbide material into the melting furnace, smelting reaction for 1-1.5h, add 10g of titanium dioxide before coming out of the furnace, and then carry out injection mold cooling. Argon.

Embodiment 3

[0038] The anti-collision material used by the automobile anti-collision protection mechanism is prepared by the following process:

[0039] (1) Add 10kg of discarded ferrous materials into an intermediate frequency induction furnace and smelt until the ferrous materials are melted into molten iron, then add 30g of boron oxide, smelt for 10-20min, then add 80g of graphite for smelting, and smelt for 50-70min;

[0040] (2) Then add 300g of silicon carbide material into the melting furnace, smelting reaction for 1-1.5h, add 20g of titanium dioxide before coming out of the furnace, and then carry out injection mold cooling, in which the intermediate frequency induction furnace is continuously fed into the medium frequency induction furnace before and during the melting process. Argon.

Embodiment 4

[0042] The anti-collision material used by the automobile anti-collision protection mechanism is prepared by the following process:

[0043] (1) Add 10kg of discarded ferrous materials into an intermediate frequency induction furnace and smelt until the ferrous materials are melted into molten iron, then add 50g of boron oxide, smelt for 10-20min, then add 110g of graphite for smelting, and smelt for 50-70min;

[0044] (2) Then add 340g of silicon carbide material into the melting furnace, smelting reaction for 1-1.5h, add 30g of titanium dioxide before coming out of the furnace, and then carry out injection mold cooling. Argon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com