Water-jet match board manufacturing method and water-jet scalpel match paving construction method

A production method and water jet technology, which are applied in special decorative structures, decorative arts, decorative structures, etc., can solve the problems that water jet parquet cannot be arbitrarily matched, it is difficult to process embedded parts and embedded parts, and it is difficult to obtain assembly effects. To achieve the effect of excellent decorative effect, low construction difficulty, and improved rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

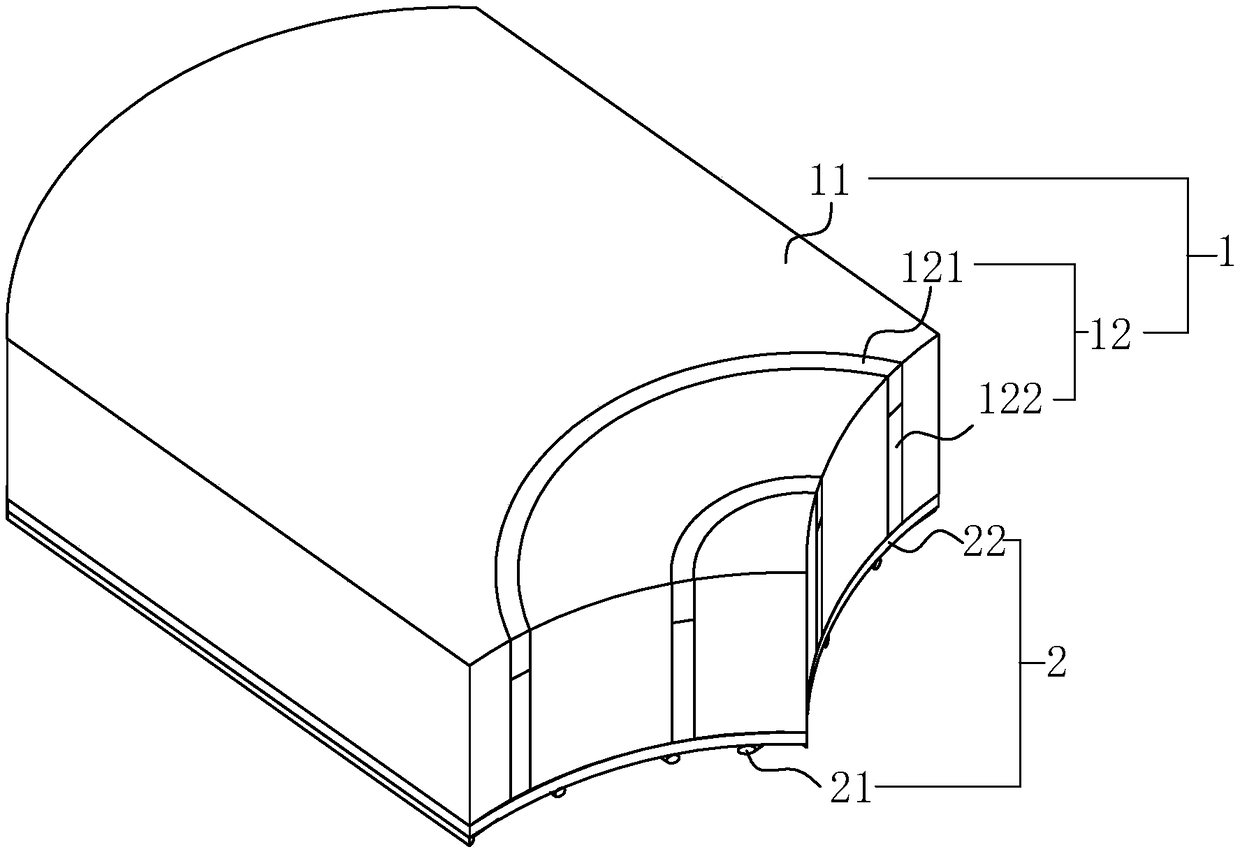

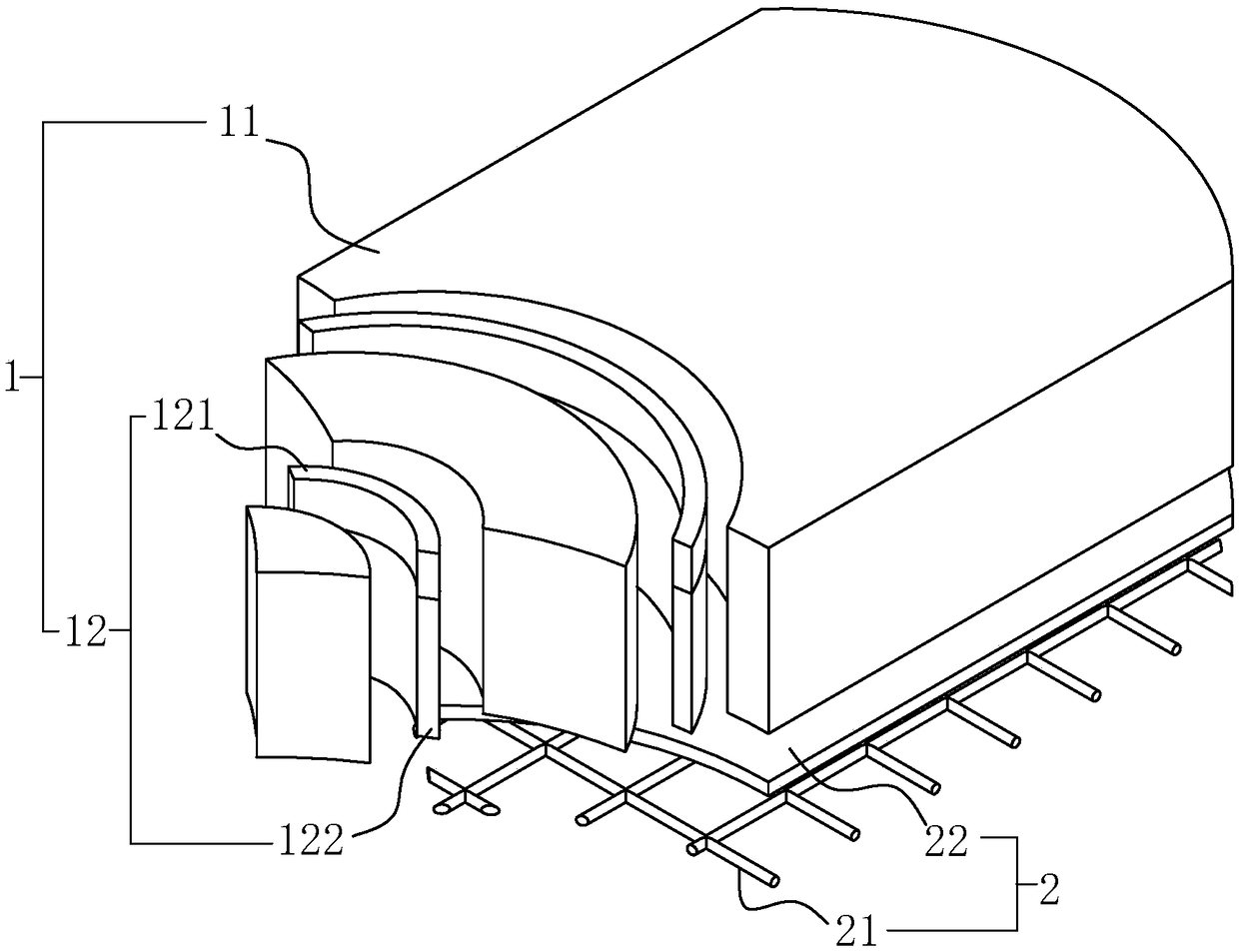

[0061] A method for making a waterjet mosaic board, this embodiment is made as figure 1 The process of the waterjet mosaic board 1 shown is taken as an example for description. figure 1 The waterjet mosaic board 1 shown is composed of three pieces of marble material 11 of different shapes and two arc-shaped strip-shaped inserts 12 embedded between adjacent pieces. In order to increase the firmness of the waterjet mosaic board 1, the back of the waterjet mosaic board 1 is also provided with an adhesive reinforcement layer 2.

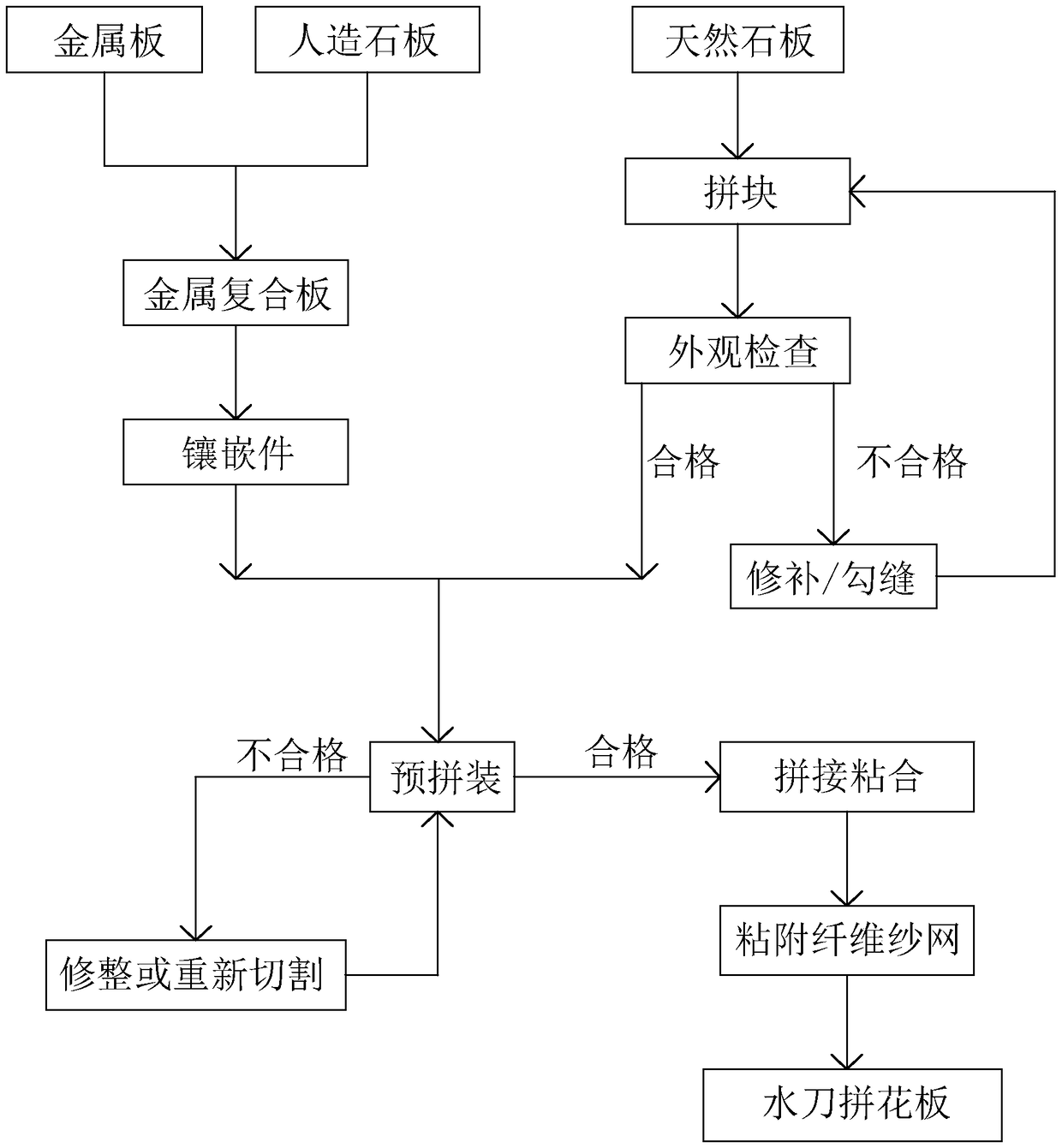

[0062] The specific production process such as figure 2 As shown, it specifically includes the following steps:

[0063] Block production, block 11 is made of 20mm thick marble slabs, cut with a water jet according to the shape of the design drawings. Such as image 3 As shown, in this embodiment, a total of three pieces 11 need to be cut to produce, and each piece 11 has an arc-shaped edge for splicing and matching with the insert 12. When choosing the marb...

Embodiment 2

[0076] A method for making a waterjet mosaic board. This embodiment is based on Embodiment 1. The difference from Embodiment 1 is:

[0077] In this embodiment, a granite slab is used as a raw material to cut and manufacture the blocks 11, and a stainless steel plate is selected as the composite board obtained by combining the metal plate 121 and the artificial stone slab 122 to be cut to manufacture the insert 12. Such as Figure 4 As shown, the waterjet mosaic board 1 in this embodiment includes three pieces 11 of different shapes and three arc-shaped strip inserts 12, one of which is located on the periphery of the waterjet mosaic board 1, and is pavement The decorative effect of metal strip inlay is also present between the rear adjacent waterjet mosaic boards 1.

[0078] In the specific manufacturing process of this embodiment, the thickness of the granite slab selected for the production of the block 11 is 17 mm; the thickness ratio of the stainless steel plate and the artific...

Embodiment 3

[0079] Example 3 Adhesive layer

[0080] A waterjet mosaic paving construction method. In this embodiment, paving the waterjet mosaic board 1 made by the method in Example 1 on the ground is described. The specific process flow is as follows Figure 5 Shown.

[0081] The base layer is leveled, the ground stones and other debris are cleaned and then leveled, and then the mortar is leveled to make the base layer 3 level to facilitate subsequent paving construction of the waterjet mosaic board 1.

[0082] For visual inspection, the waterjet mosaic board 1 prefabricated by the method in Example 1 is selected in this embodiment, and the waterjet mosaic board 1 needs to be visually inspected before use. If there are slight bumps or scratches, repair and joint treatment shall be carried out to avoid affecting the overall decorative effect after paving. The specific steps for repairing joints are as follows:

[0083] P1. Use epoxy resin (E-44), stone powder, pigments, acetone, hexamethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com