Wind fire-extinguishing machine air duct

A wind-powered fire extinguisher and machine wind technology, which is applied in fire rescue and other directions, can solve the problems of affecting the air volume at the outlet of the wind-powered fire extinguisher, reducing the fire extinguishing efficiency, and deformation of the air duct mouth, so as to enhance the strength, reduce the loss of air volume, and not easily deform or damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment, wind fire extinguisher air duct of the present invention is further described:

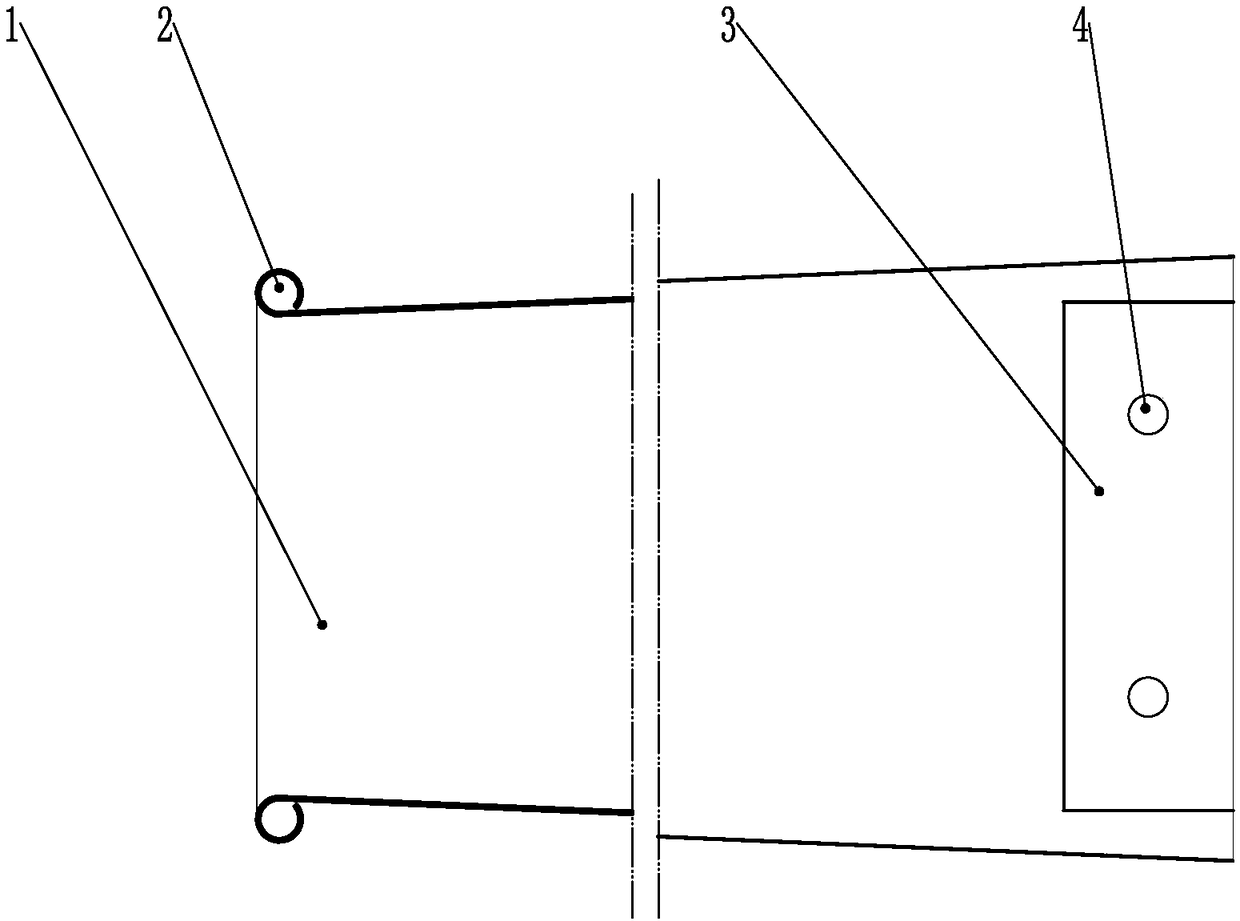

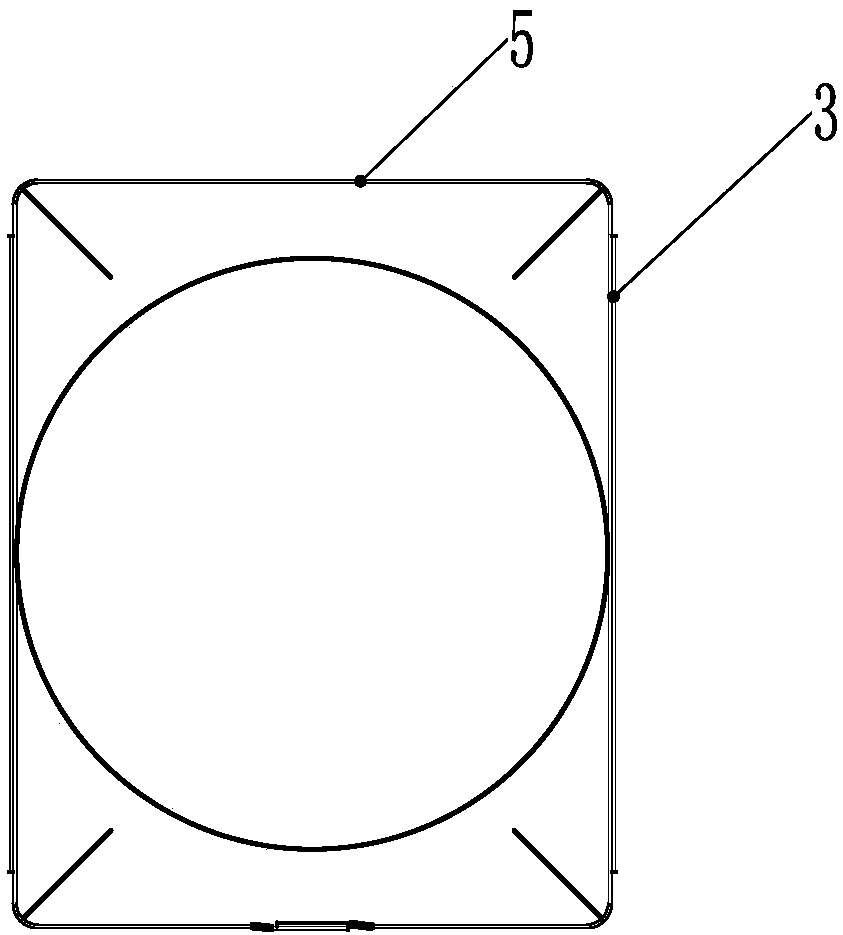

[0012] figure 1 It is a structural schematic diagram of the air cylinder of the wind fire extinguisher of the present invention. In the figure, the air cylinder 1 of the wind fire extinguisher is formed by rolling iron sheets, and one end of the air cylinder 1 is circular, and a circular flange 2 is arranged at the circular opening from the inside to the outside. The other end of the air duct 1 is square, and a reinforcing plate 3 is spot-welded on both sides of the square opening 5, and a circular hole 4 is arranged on the reinforcing plate 3.

[0013] The above description is only a preferred embodiment of the present invention, and does not limit the present invention in any form. Although the present invention has been disclosed as above with preferred embodiments, it is not intended to limit the present invention....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com