Movable turn-taking backwash net type filter

A screen filter and backwashing technology, which is applied to fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problem of inability to complete filter backwashing at the same time, uneven stress on the filter screen, and increased operating costs And other problems, to achieve the effect of not easy to deform, easy to operate, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

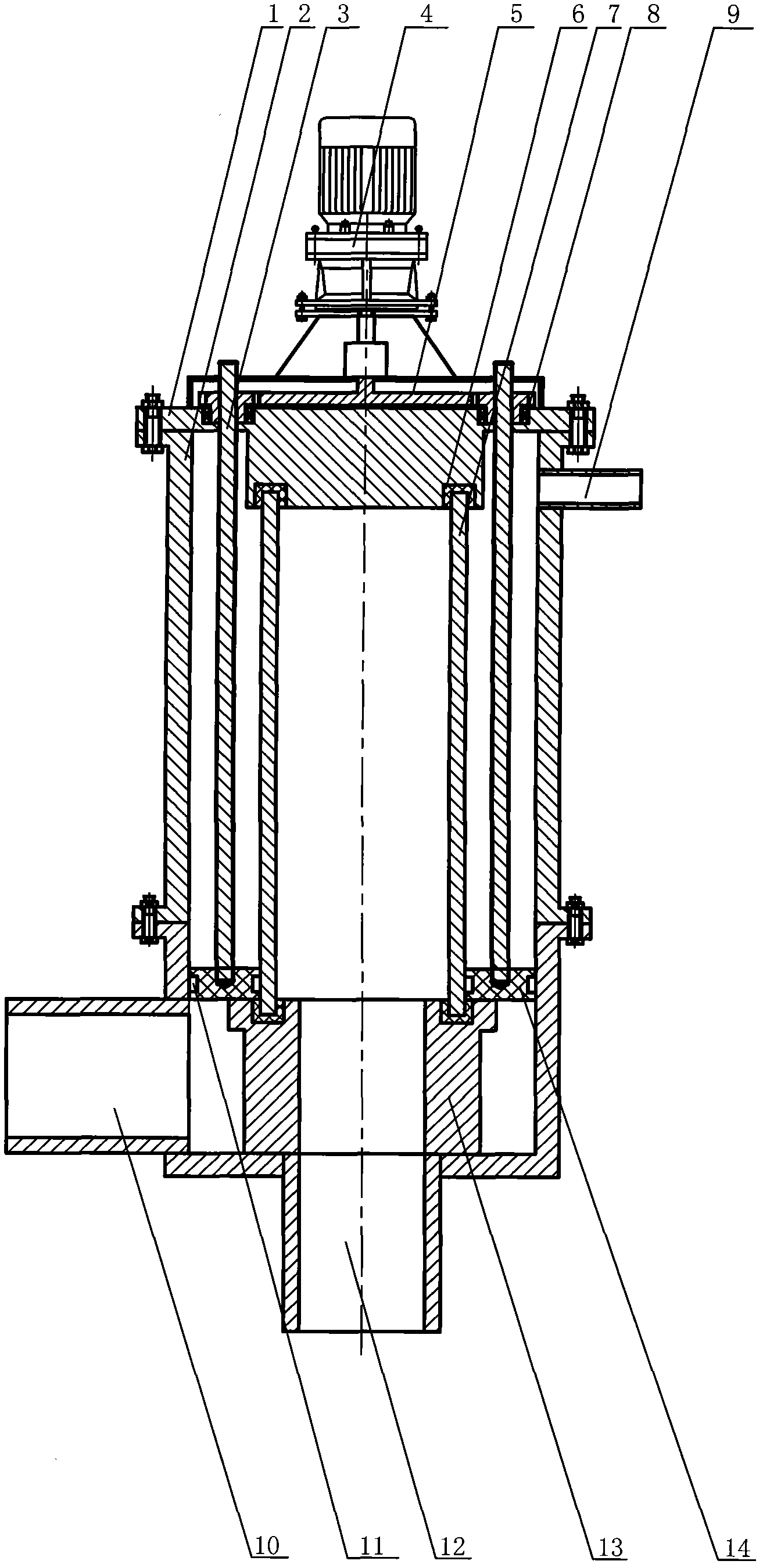

[0008] figure 1 It is a structural schematic diagram of an embodiment of the mobile alternate backwashing screen filter of the present invention. The two ends of the housing 2 are provided with an upper gland 1 and a base 13, and the outer wall of the housing is provided with a sewage pipe 9 near the upper gland, and the upper gland is connected with the external force device 4 through the same direction gear transmission 5, and the base The bottom end is provided with a water outlet 12, and its outer wall is provided with a water inlet 10. The inside of the shell is provided with a mesh filter element 7, and the two ends of the mesh filter element are sleeved in the "U In the "shaped rubber ring 6, a circular partition 14 is arranged between the outer wall of the mesh filter element and the inner wall of the housing, and ring grooves are respectively arranged on the inner and outer walls of the ring partition, and a large mechanical seal device 11 is arranged in the ring groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com