Laser cladding deformation control method for slender piston rod

A laser cladding and deformation control technology, applied in metal material coating process, coating and other directions, can solve the problem of partial cladding part being too thick, piston rod deformation, iron leakage, etc. The effect of less powder and small spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

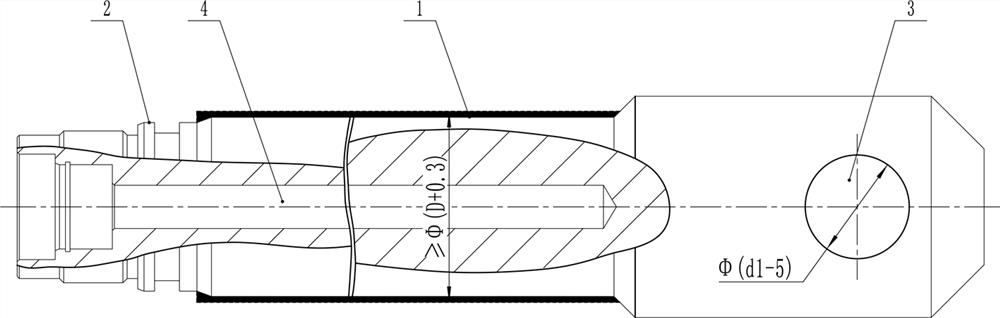

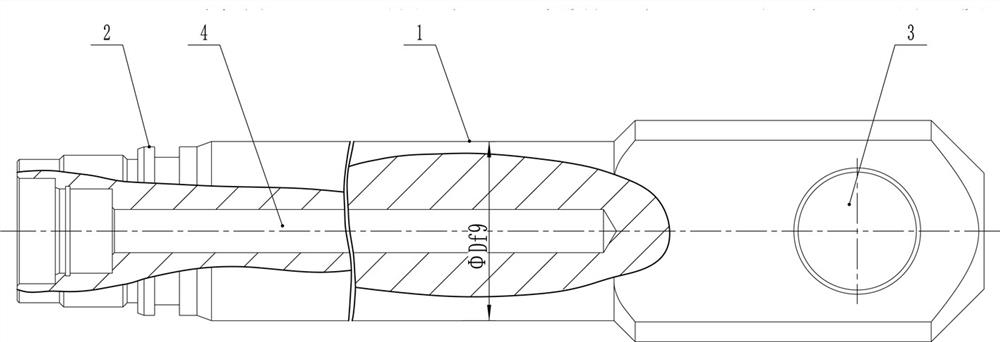

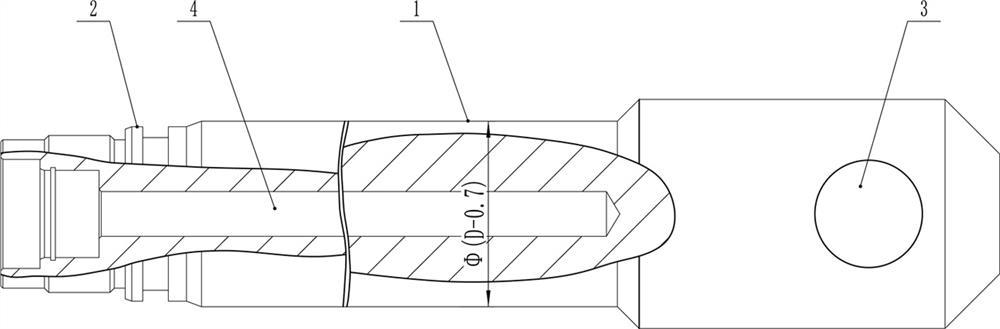

[0032] Such as Figure 1-Figure 3 As shown, a slender piston rod laser cladding deformation control method is used to process a piston rod with an outer circle of φ70mm in the cladding area. In the figure, D refers to the cladding diameter, which includes the following steps:

[0033] Rough turning: Turn out the outline of the slender piston rod, and reserve a size of 78mm. The purpose is to overcome the problem of stress springback after straightening and leave more dimensions for subsequent processing and removal.

[0034] Drill hinge holes 3.

[0035] Quenching and tempering: The slender piston rod workpiece is placed in the furnace vertically and vertically into the tank to avoid mutual extrusion, and the workpiece can move up and down evenly.

[0036] Straightening: Use tools to straighten the slender piston rod to reduce the bendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com