Fabricating method for laptop outer casing with fibrage texture

A fiber weaving, computer shell technology, applied in the direction of electrical digital data processing, instruments, digital data processing components, etc., can solve the problems of fiber structure weaving deformation protrusions, thermal deformation, etc., to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, other features and advantages of the present invention will be further described with preferred embodiments of the present invention with reference to the accompanying drawings.

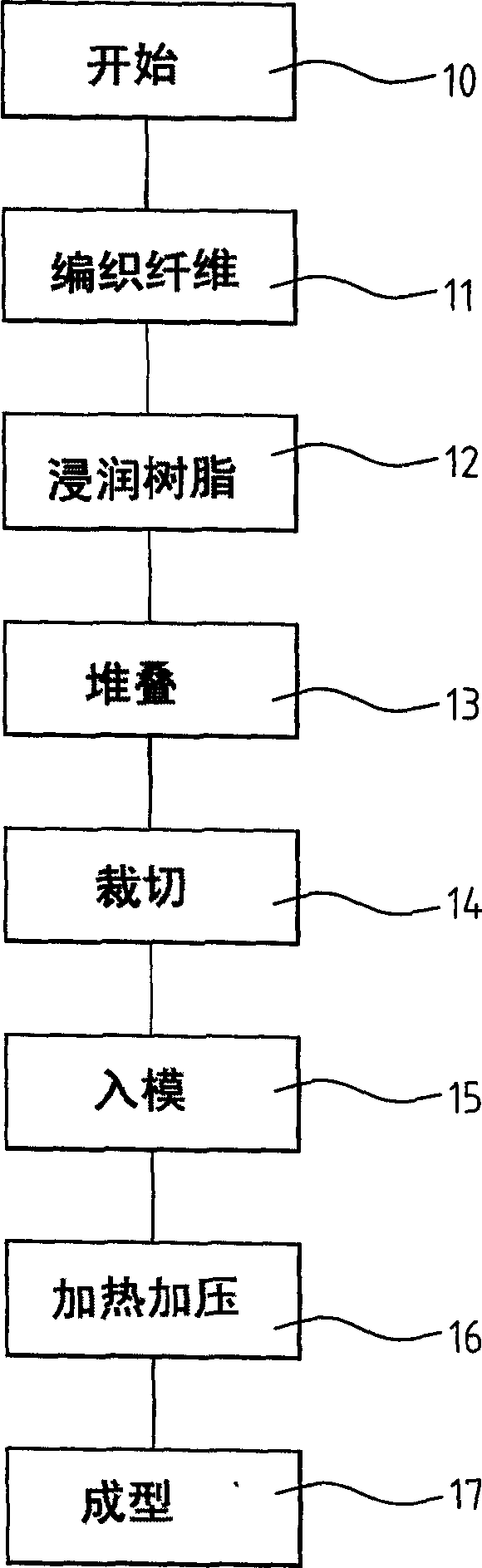

[0019] Please refer to figure 1 is a flow chart showing the method for manufacturing a notebook computer casing with fiber weaving textures of the present invention.

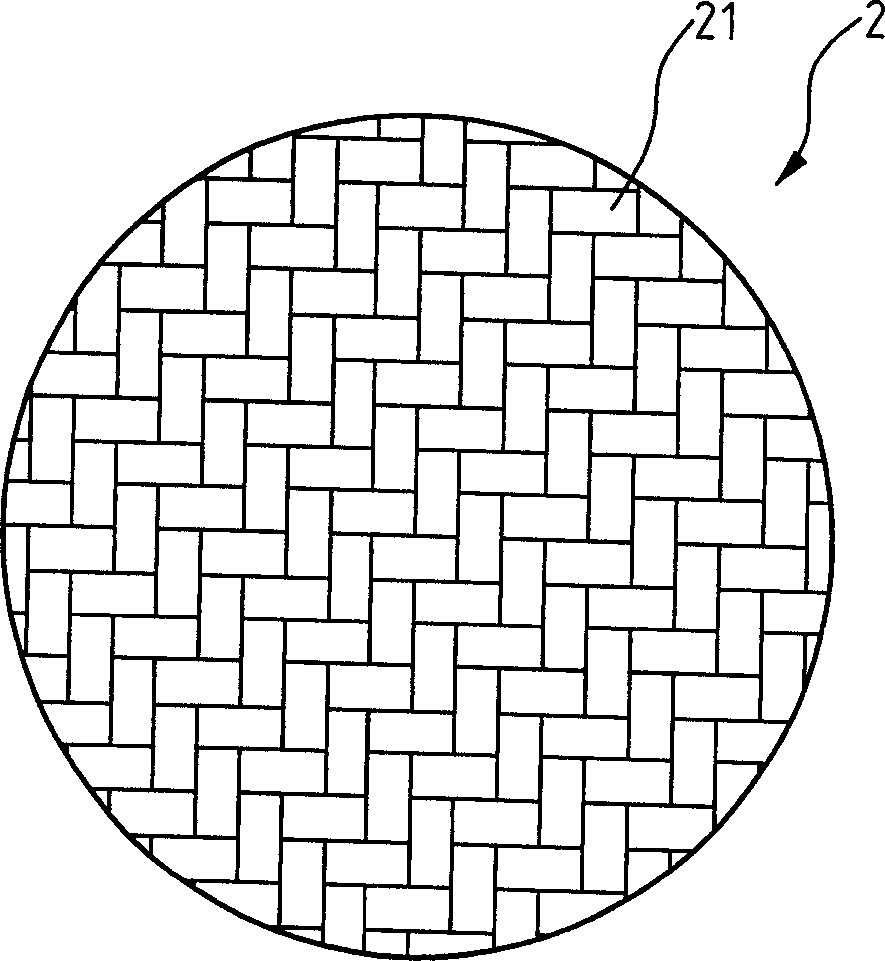

[0020] The flow chart starts at step 10, first in step 11 fibers are provided and braided fibers are formed. Please also refer to figure 2 In the illustrated embodiment of one of the braided fibers, the fibers 21 are criss-crossed to produce special textures. Wherein, the fiber 21 may include carbon fiber, glass fiber and Kevlar.

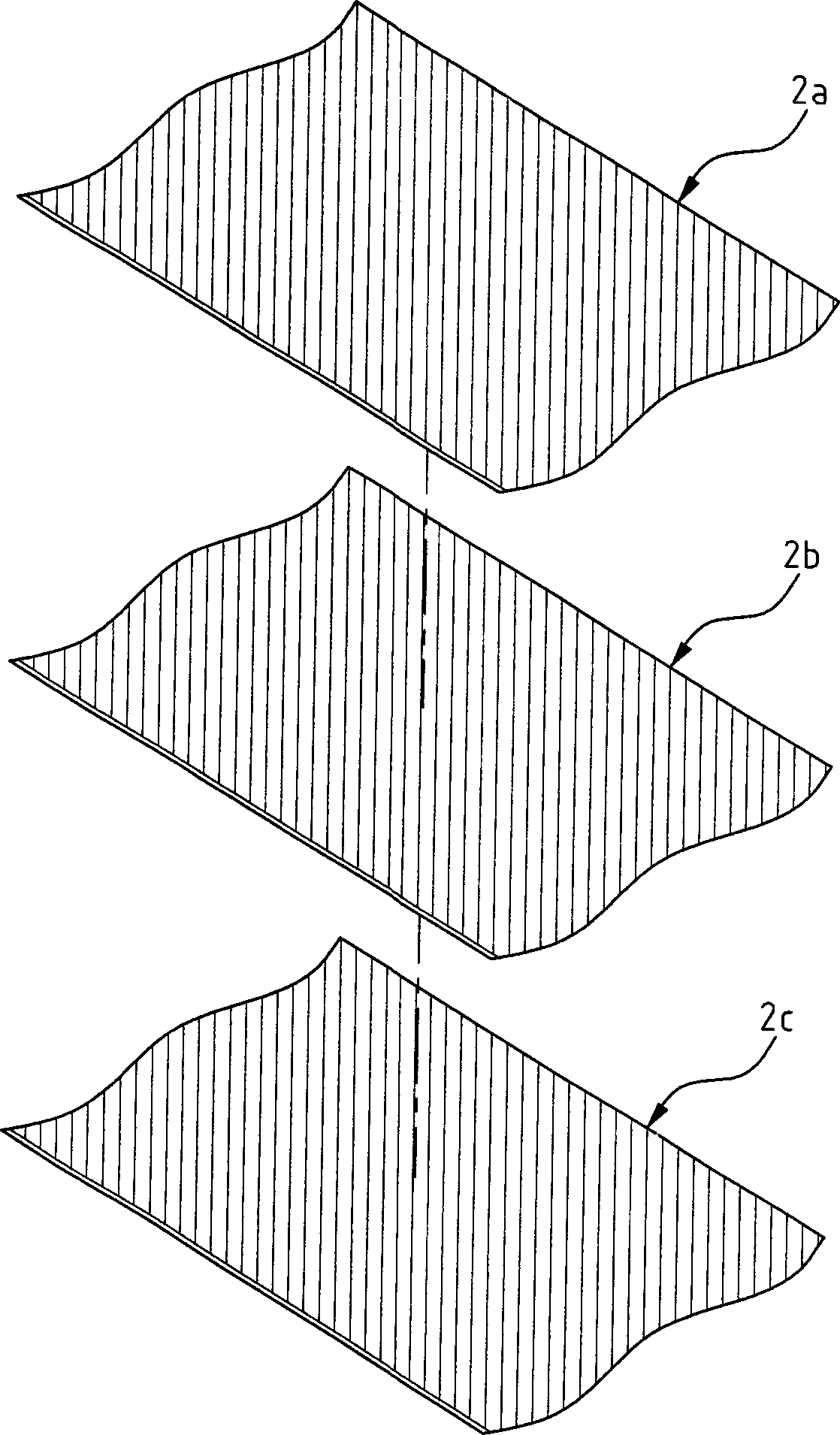

[0021] Next, in step 12, the textured braided fibers 2 are soaked in resin. Then in step 13: stack these braided fibers, and make the angles of the braided grains of the uppermost layer and the lowermost layer completely aligned and in the same direction. Please refer to Figure 3A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com