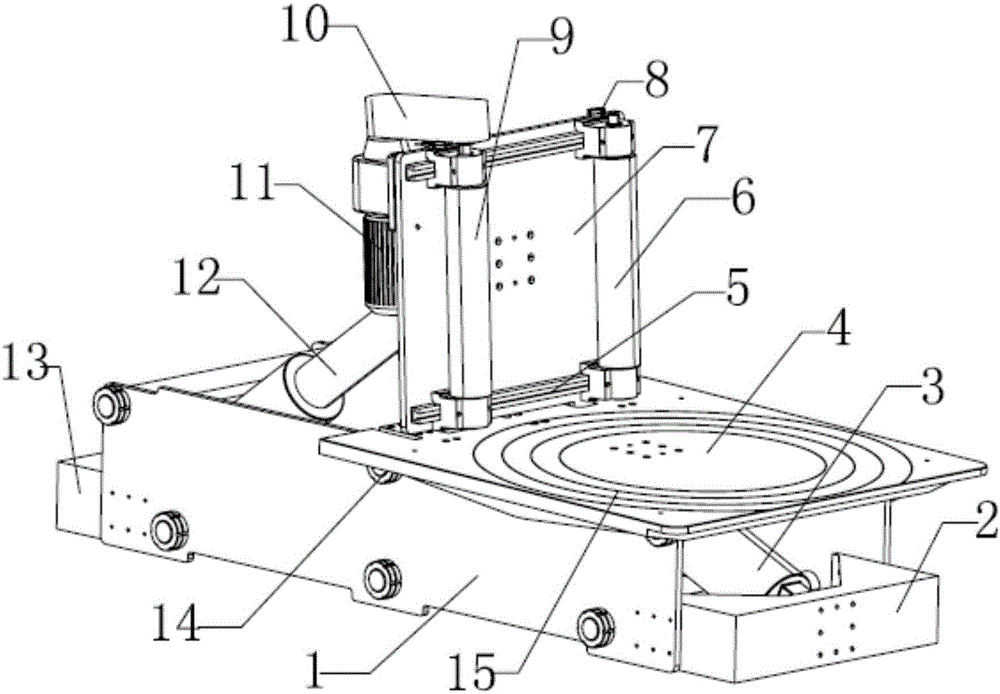

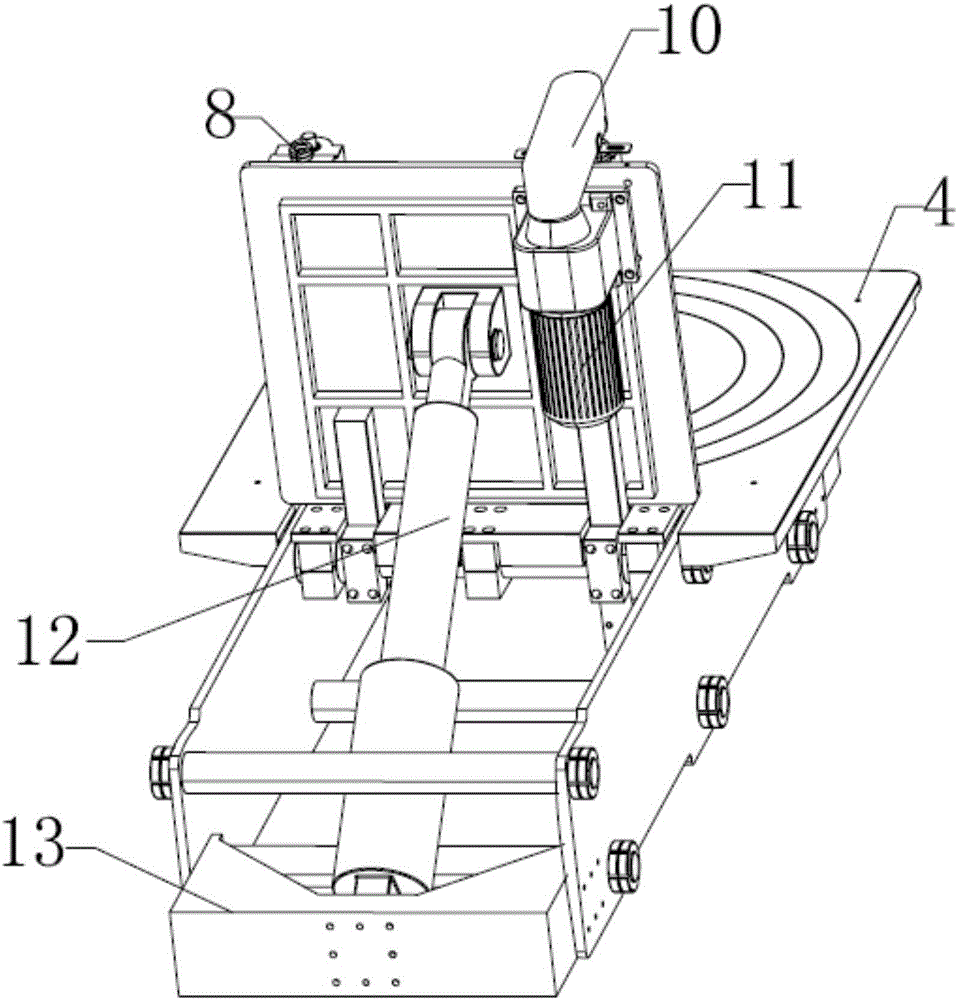

Large-scale stator core turnover welding device

A stator core and welding device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor quality assurance, serious bump damage, and high labor intensity, so as to reduce labor intensity , Not easy to deform, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] work process:

[0019] First, put the tooling base plate and the tooling mandrel on the base plate 4, stack the punching sheets to the required height, press the cover plate, turn over the cylinder 12 after starting, and then extend the piston rod of the turning cylinder 12 until the backing plate 7 just leans against the punching plate. Then the piston rod of the back turning cylinder 12 shrinks, and at the same time the front turning cylinder 3 starts, the piston rod of the front turning cylinder 3 stretches, and the whole punching piece gradually moves to the backing plate 7, until the backing plate 7 is in a horizontal state , clamp the tooling base plate and cover plate with a clamp, start the motor 11, automatically rotate at 0°, 180°, 90°, 270° and manually weld until the outer diameter welding is completed, loosen the clamp, remove the tooling base plate and cover plate, and place the The entire punch is lifted out.

[0020] The invention effectively solves the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com