Integrated box allowing punching and ring pressing at same station

A co-location and pressure ring technology, applied in the field of clothing production equipment, can solve the problems of staff fatigue and affect assembly efficiency, and achieve the effects of reducing fatigue, saving cost and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

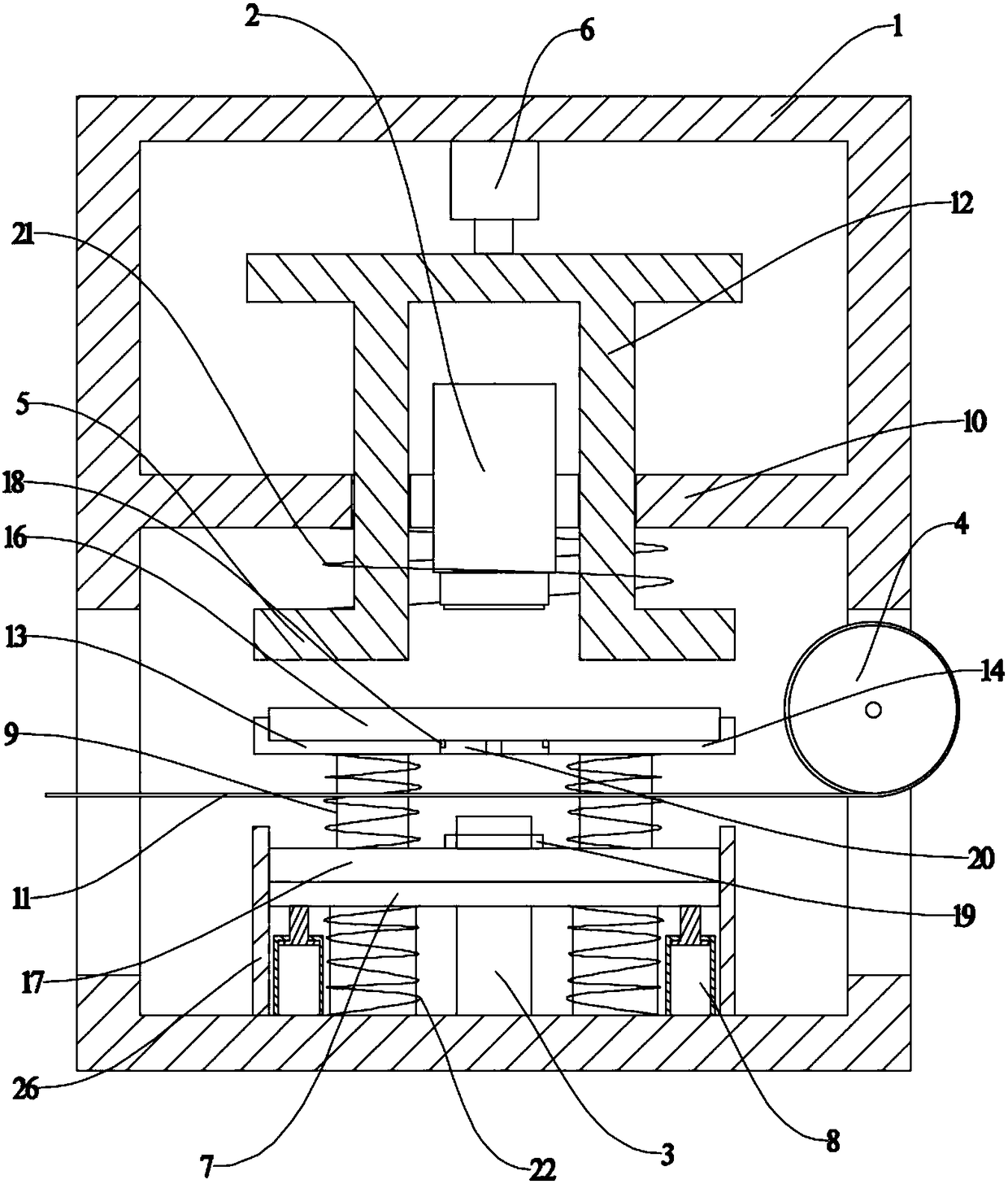

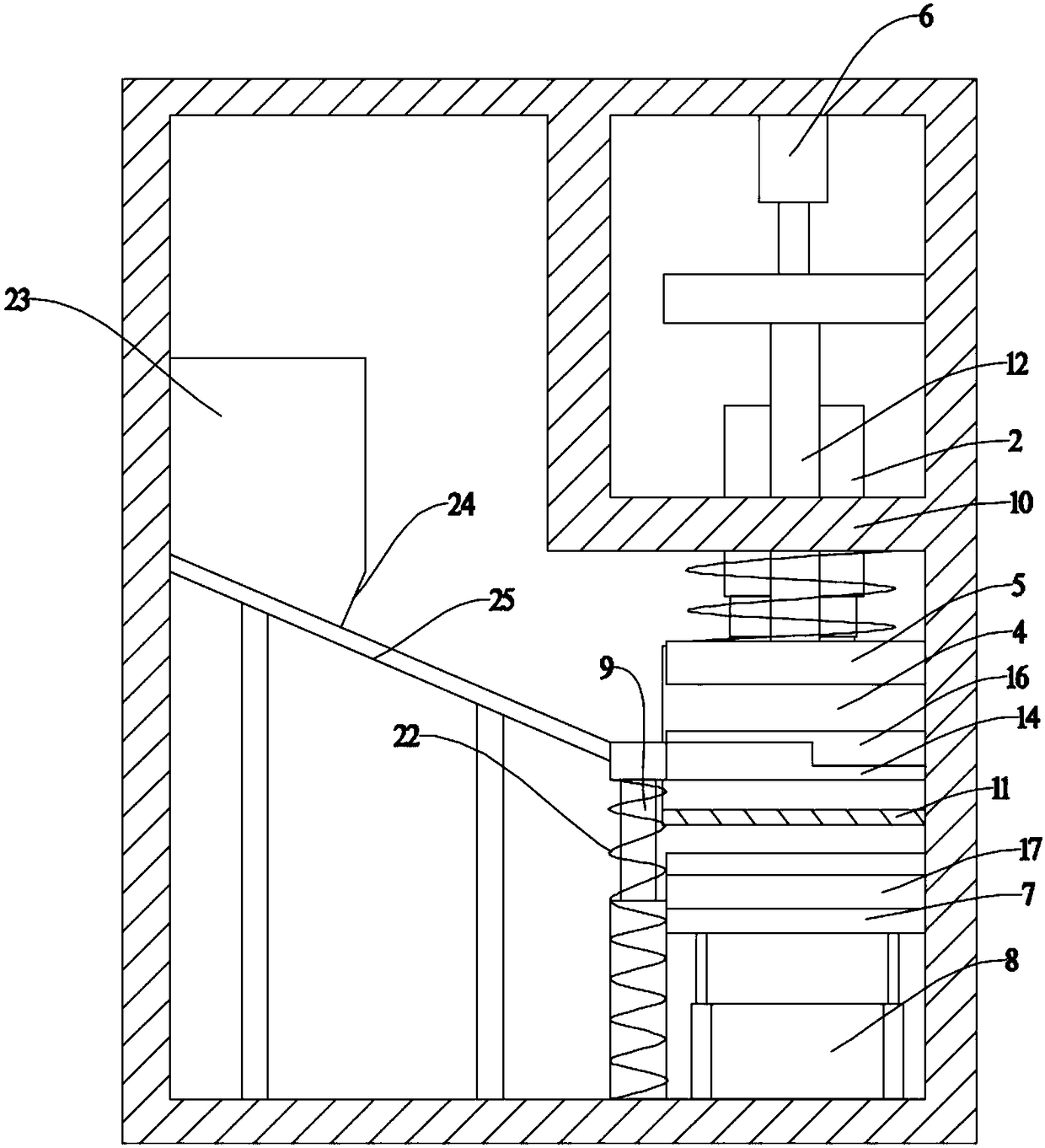

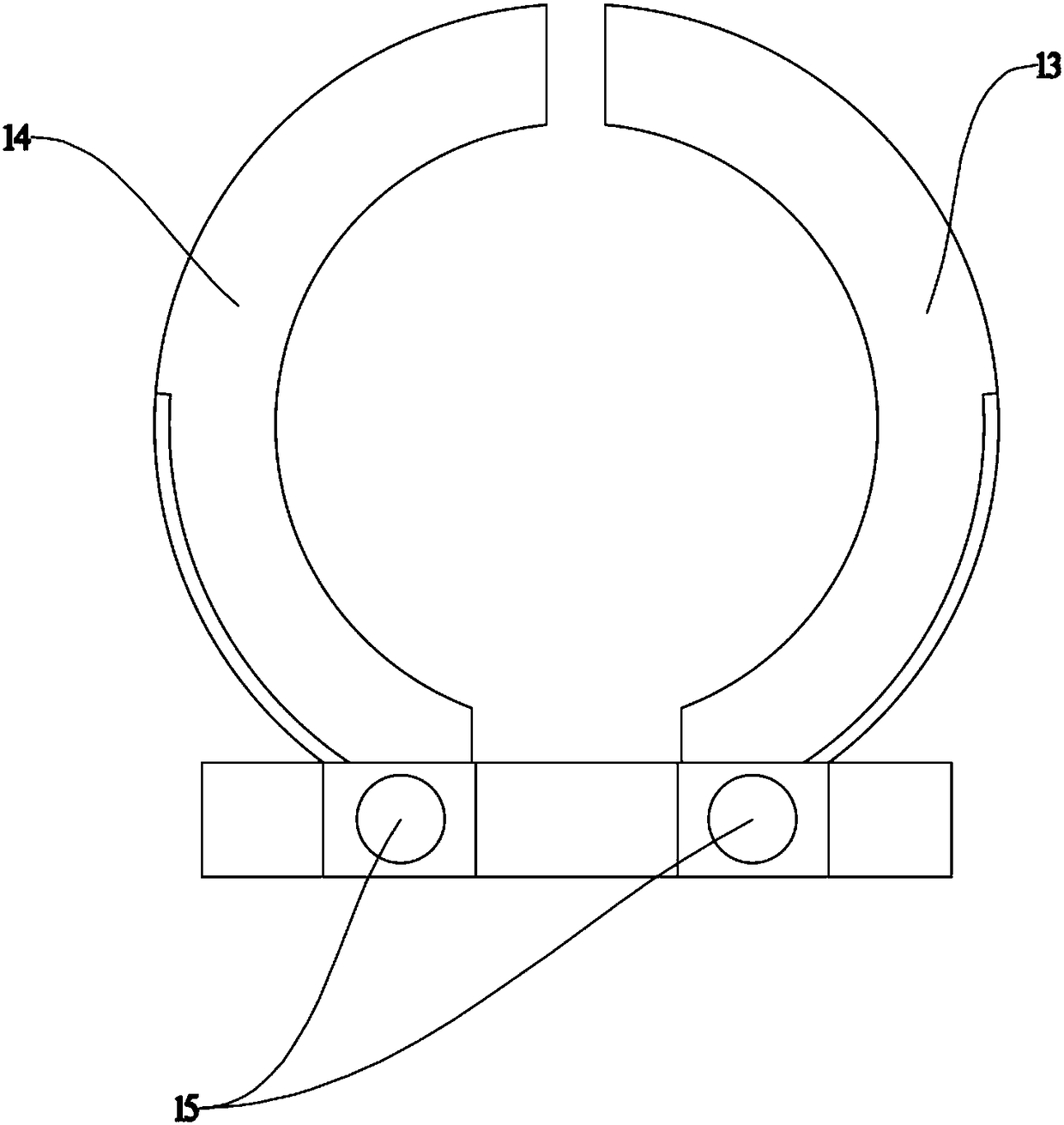

[0022] see figure 1 And attached figure 2 , a punching and pressing ring co-located integrated box, used for opening holes on the cloth and installing hollow rings at the openings, including a box body 1, a punch 2, a punch seat 3 and a cloth feeding reel 4, the punch Hole pressure ring co-positioning integrated box also includes stamping plate 5, stamping plate cylinder 6, adornment ring seat 7, adornment ring seat cylinder 8, upper pressing ring positioning plate, upper pressing ring feeding device 23 and lower pressing ring positioning plate (26), A mounting plate 10 is set up in the middle of the box body 1. The mounting plate 10 is provided with an installation through hole. The punch seat 3 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com