Slice antenna and manufacturing method thereof

A manufacturing method and antenna technology, applied to antennas, electrical short antennas, antenna supports/mounting devices, etc., can solve the problems of unfavorable cost saving and complicated manufacturing process, and achieve the effect of convenient manufacturing method, low cost, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

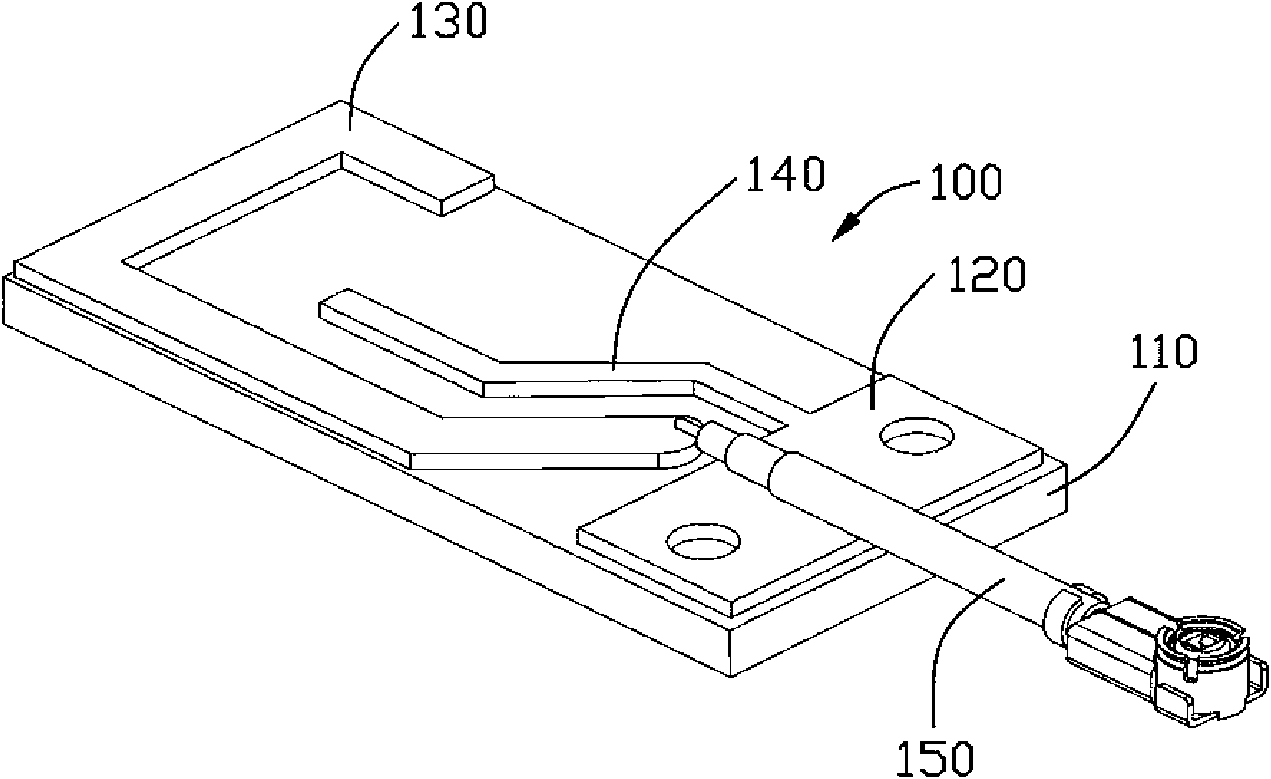

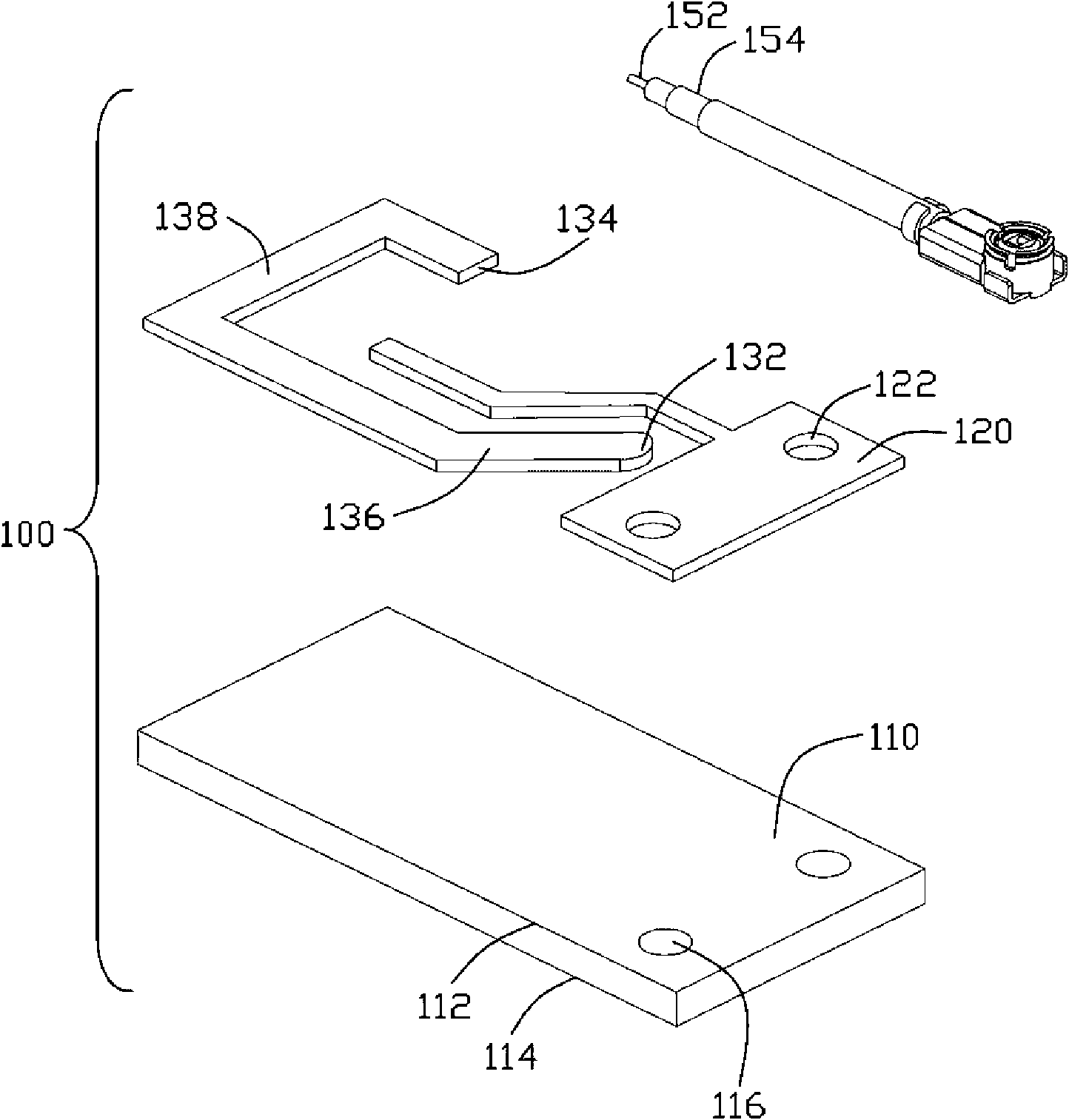

[0015] refer to figure 1 , figure 2 As shown, the chip antenna 100 in the figure is manufactured according to the antenna manufacturing method of the present invention. The chip antenna 100 includes a substrate 110 , a conductive foil (marked as a symbol) fixed on the substrate 110 , and a feeder 150 . The conductive foil is divided into two parts, including a ground part 120, a radiation part 130 set apart from the ground part 120, a parasitic metal arm 140 connected to the ground part 120 and separated from the radiation part 130, wherein the ground part 120 and the parasitic metal arm 140 is the first part, and the radiation part 130 is the second part. In this embodiment, the conductive foil is copper foil. In other embodiments, the conductive foil can be other metal foils, such as metal foils made of single metals such as gold, silver, aluminum, or metal foils formed by alloys. Conductive metals or their alloys are vapor-deposited, water-plated or coated on insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com