PCB rubberizing method

A kind of PCB board and glue technology, which is applied in the direction of PCB tool positioning, electrical components, and simultaneous processing of multiple printed circuits. and other problems, to achieve the effect of high patch efficiency, easy fixing, and guaranteeing the yield of the patch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

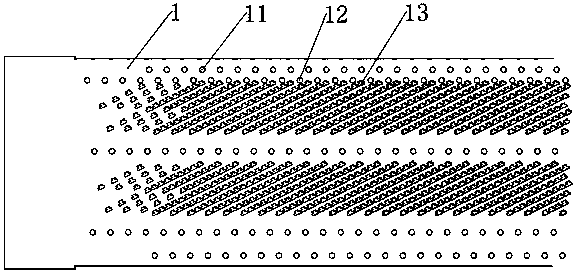

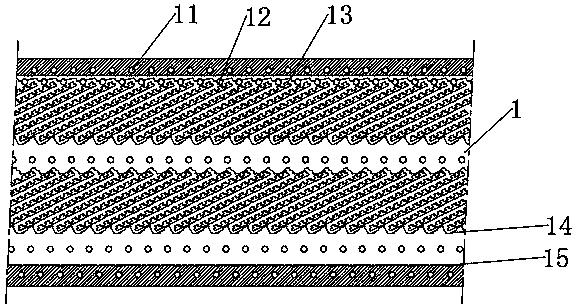

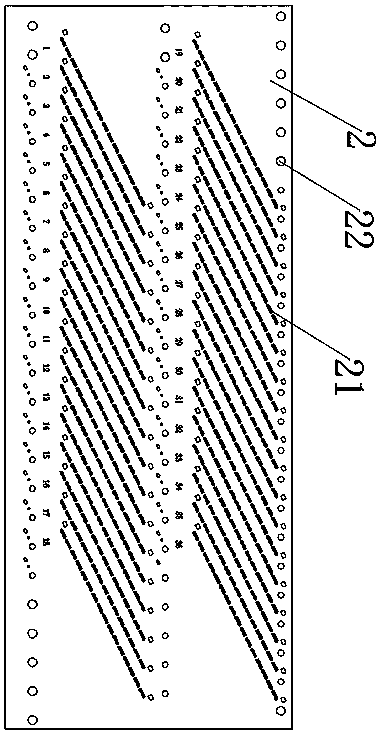

[0026] refer to Figure 1~Figure 6 , a method for sticking glue on a PCB, comprising the following specific steps:

[0027] S1. Refer to image 3 , The whole PCB board production, making the whole PCB board including multiple single boards; during production, the layout of each PCB single board on the whole PCB board is arranged according to the shape of the PCB single board, so as to improve the utilization rate of PCB materials as much as possible . According to the layout, make the whole PCB board 2 and then complete the subsequent steps after patching and welding components. Using the method of patch welding first and then completing the subsequent steps, it can be patched on a large PCB entire board, and the patching efficiency is high. And when welding, the large whole board is easy to fix on the jig and is not easy to deform. In addition, it avoids the high temperature damage of the adhesive strip when bonding first and then welding. The specific placement and welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com