High dryness dewatering method and equipment for high moisture content sludge

A technology with high water content and water content, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of uneconomical, intracellular water is easy to be pierced, etc., to save floor space, improve dehydration efficiency, reduce The effect of small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

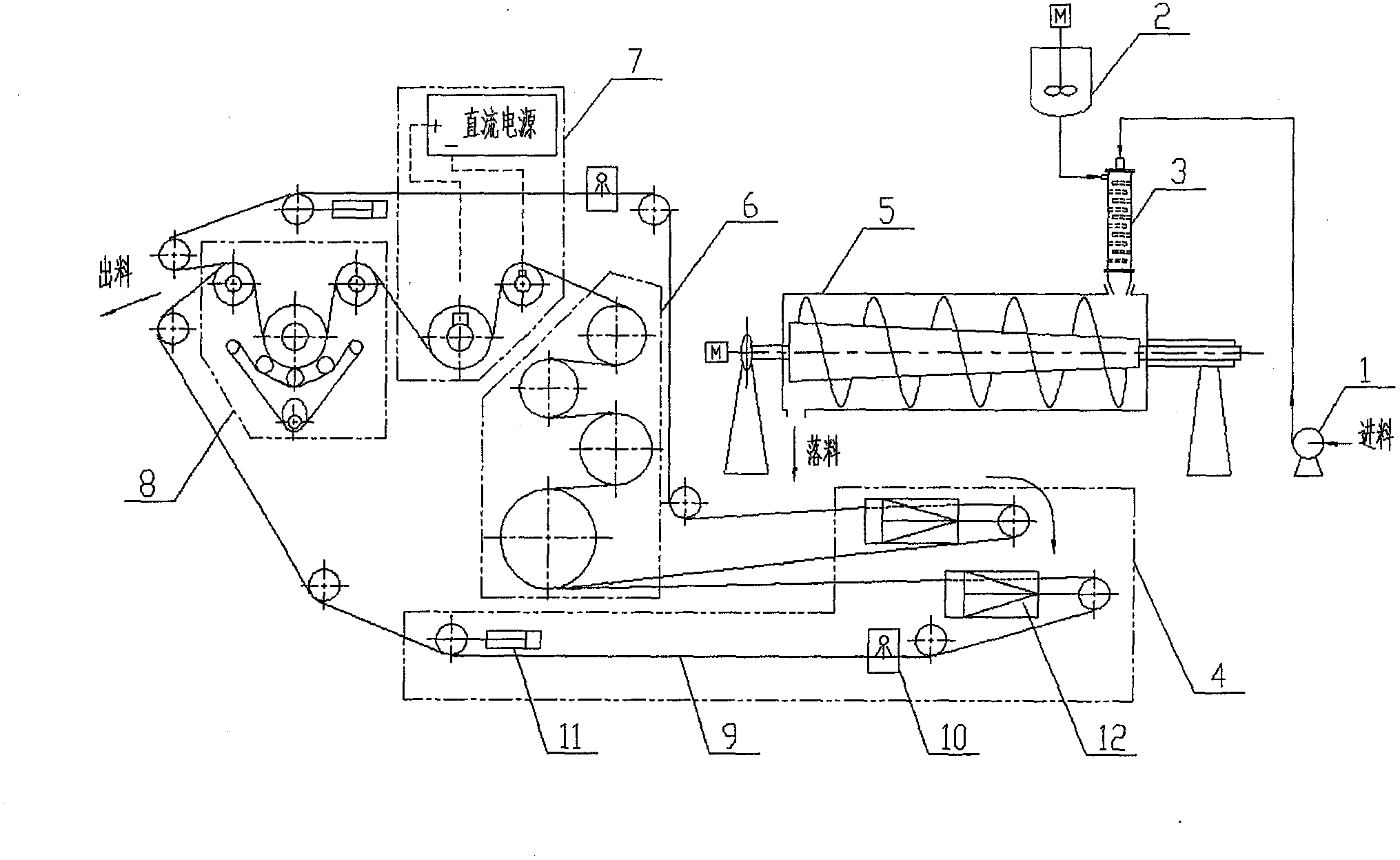

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments.

[0027] The sludge with a water content of 98% in the secondary settling tank is pumped into the pipeline mixer by the screw pump and mixed with the flocculant polyacrylamide, and the flocculated sludge after the reaction of the pipeline mixer flows into the spiral pre-concentration dewatering drum for concentration and dehydration. The structure of the spiral pre-concentration dewatering cylinder is cone-shaped, that is, the sludge is climbing in the spiral pre-concentration dewatering cylinder, so that the water flows backward and the mud moves forward, which is conducive to dehydration. , the working process is flocculation and dehydration at the same time, which plays a better role in concentration and dehydration of sludge. The spiral dehydration time is selected as 2min, and the moisture content of the sludge at the outlet of the spiral dewatering cylinder is measured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com