Oil-water separation system and separation method

An oil-water separation and separation system technology, applied in separation methods, liquid separation, dehydration/demulsification by mechanical methods, etc., can solve the problems of complex composition, difficult deep separation, etc. The effect of long-term sustainable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

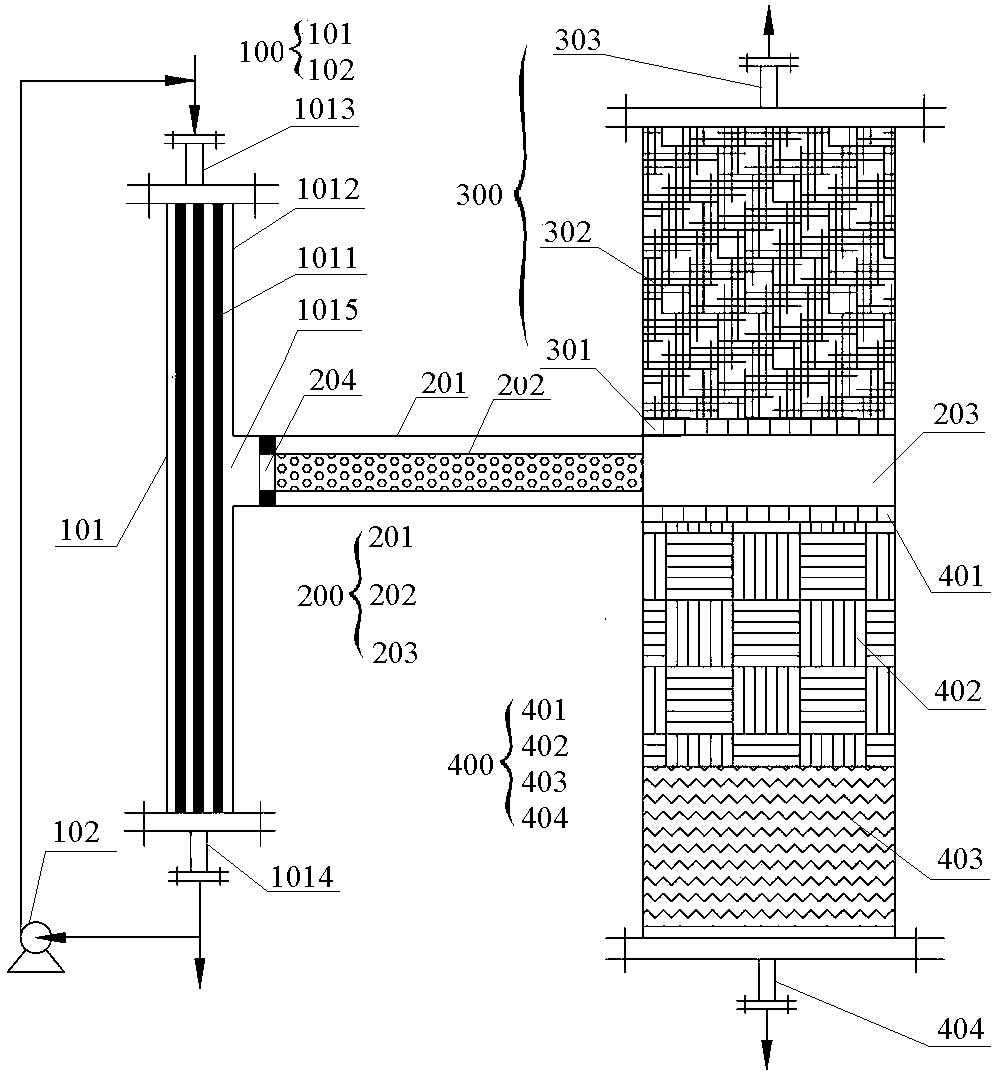

[0046] The oil-water separation system in Example 1 is used for dehydration and separation of light-phase oil products. The oil product to be separated enters the membrane tube 1011 from the feed port 1013 of the membrane module, and under the filtering action of the membrane tube 1011, the liquid penetrates into the housing 1012 In the process, the remaining concentrated material in the membrane tube 1011 is discharged from the discharge port 1014 of the membrane module, enters the circulation pump 102 and continues to enter the membrane module 101 for multiple filtration and demulsification; The separation system 200 first enters the middle cavity of the hollow filter element 202 from the feed port 204 of the feed pipe. Under the action of the hollow filter element 202, the larger water droplets in the oil are separated and left in the middle of the filter element, while the rest of the material is filtered In the cavity of the hollow filter element 202 and the feed pipe 201,...

Embodiment 3

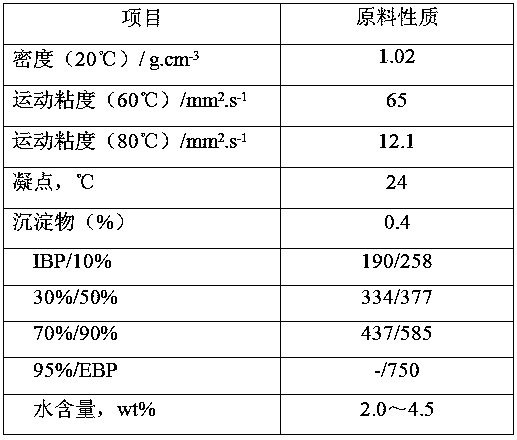

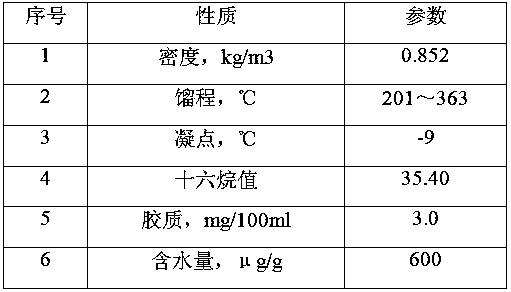

[0049] The oil-water separation system of Example 1 was used to dehydrate catalytic light diesel (oil is light phase). The properties of the raw oil are shown in Table 1, and the operation process was as described in Example 2. The specific operating conditions are: operating temperature: 40-45°C; operating pressure: 0.3MPaG; residence time: 3.2 minutes.

[0050] After oil-water separation, the water content of the catalytic light diesel oil is 42-88ppm.

Embodiment 4

[0061] An oil-water separation system, which is different from the system in Example 1 in that the upper coalescing and separation zone 302 is made of polyester fibers (lipophilic and hydrophobic) and polypropylene fibers (hydrophilic and oleophobic) mixed and woven in a ratio of 4:1 The X-shaped fiber layers with a dense concave-convex structure are stacked; the lower coalescence and separation zone 402 is made of polyester fibers (oleophilic and hydrophobic) and polypropylene fibers (hydrophilic and oleophobic) mixed in a ratio of 1:5. X-shaped fiber layers with a concave-convex structure are stacked; other structural settings are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com