Press type sludge dehydration equipment

A technology of sludge dewatering and pressing arm, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve problems such as uneconomical, increased sludge treatment cost, and insufficient utilization of resources in garbage disposal sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

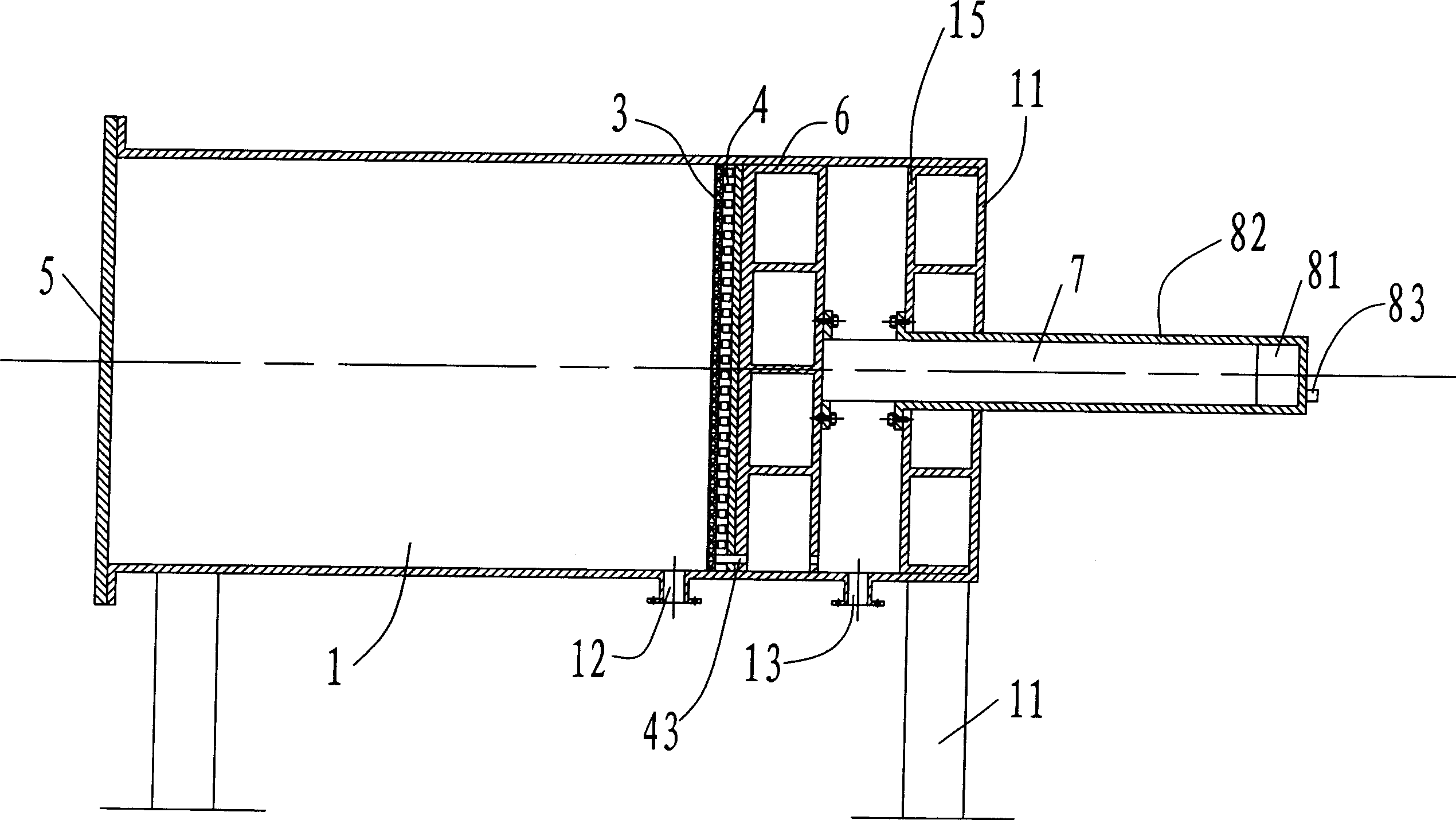

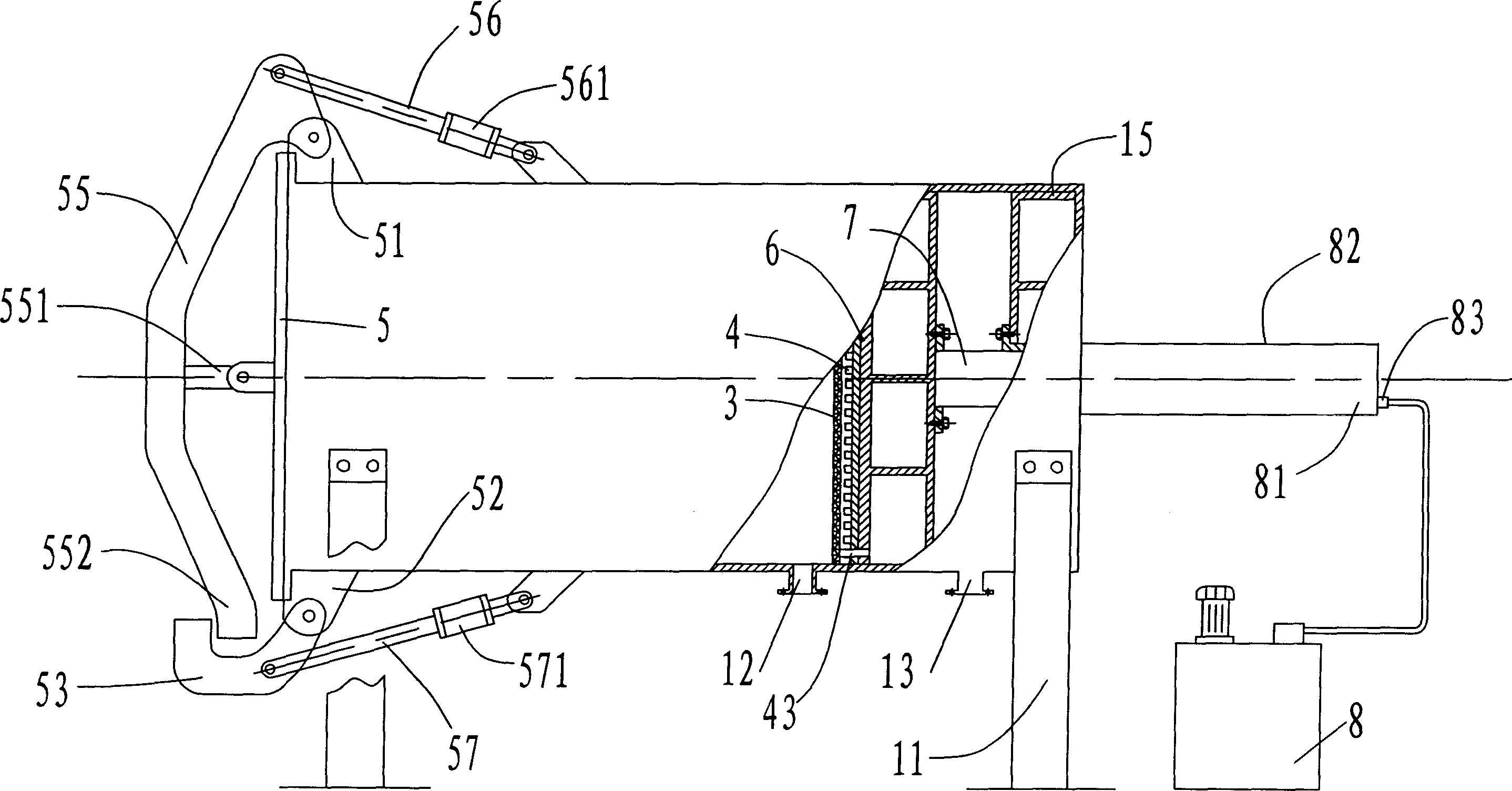

[0010] Refer to attached figure 1 , in one implementation of the present invention, the pressing sludge dewatering device specifically includes a filter chamber 1 with a feed port 12 and a discharge port 13 on the side wall, the filter chamber 1 can be placed and fixed on a frame 11, and The feed port 12 is connected with the sludge pump in the usual way; it also includes a filter plate 4, which faces the surface of the filter chamber 1, that is, the front of the filter plate 4 is wrapped with a filter cloth 3, and the filter plate 4 is set There is a filtrate discharge channel 43 communicating with the drain port 13; the present invention particularly makes the filter chamber 1 a cylindrical filter chamber, and the port at the front end of the filter chamber 1 is sealed and closed by an openable thrust cover plate 5, and the filter chamber 1 The rear end is closed by the baffle plate 11; the filter plate 4 is placed in the filter chamber 1 and set opposite to the thrust cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com