Lithium nickel cobalt manganate cylindrical high-rate battery and preparation method thereof

A nickel-cobalt lithium manganate, high-rate technology is applied to the high-safety nickel-cobalt lithium manganate cylindrical high-rate battery and its preparation field, and can solve the problems of increasing battery safety hazards and complex production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

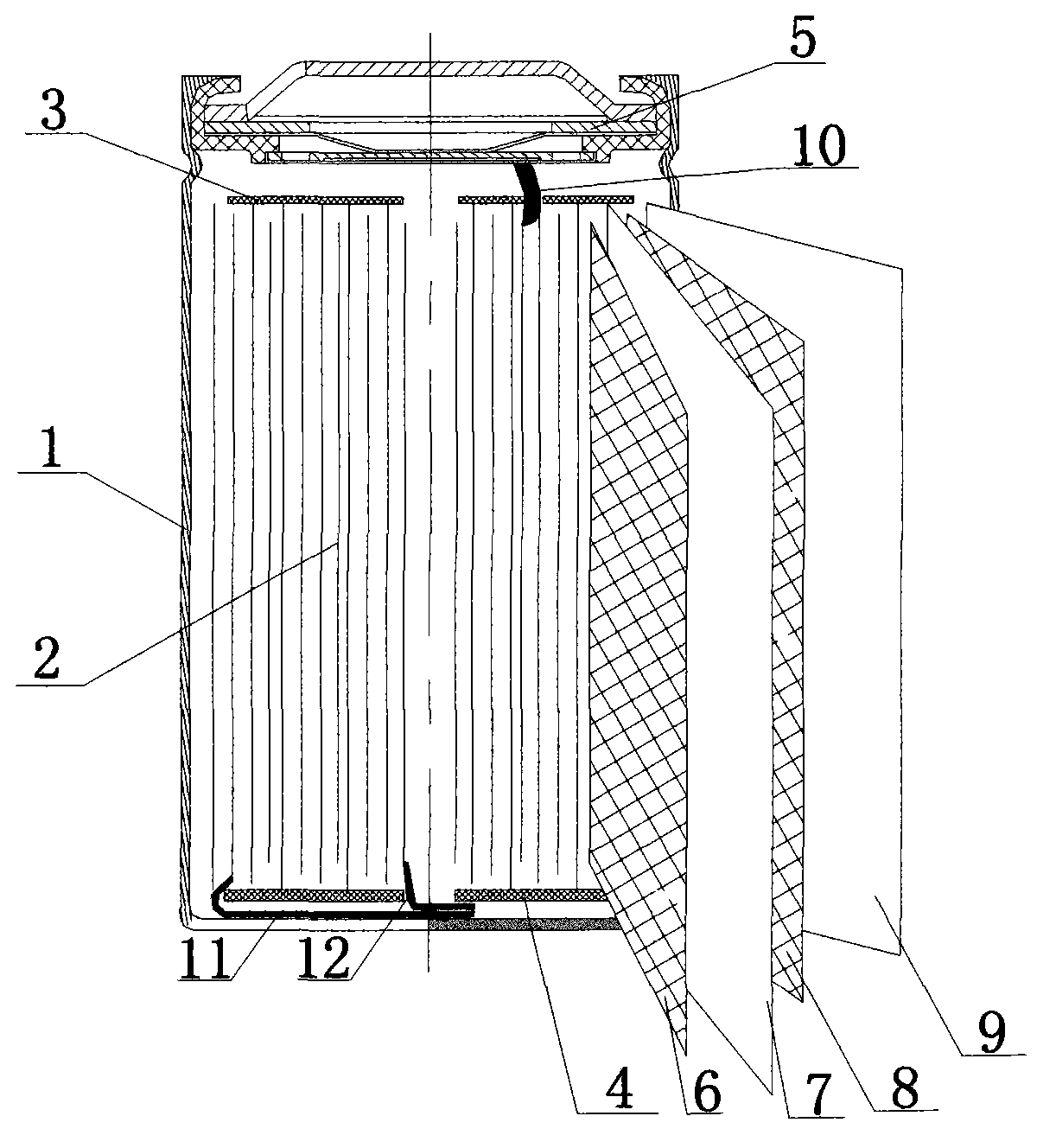

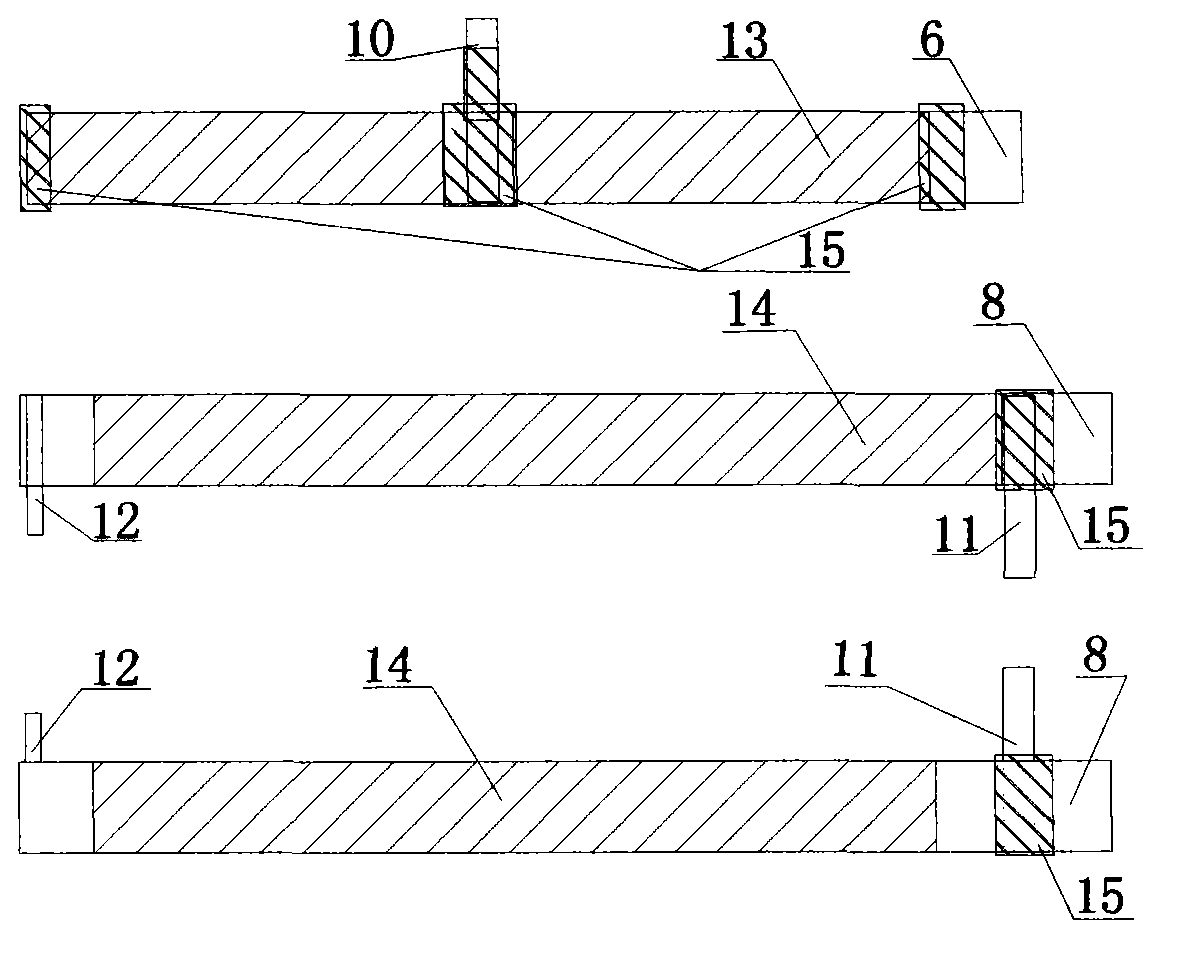

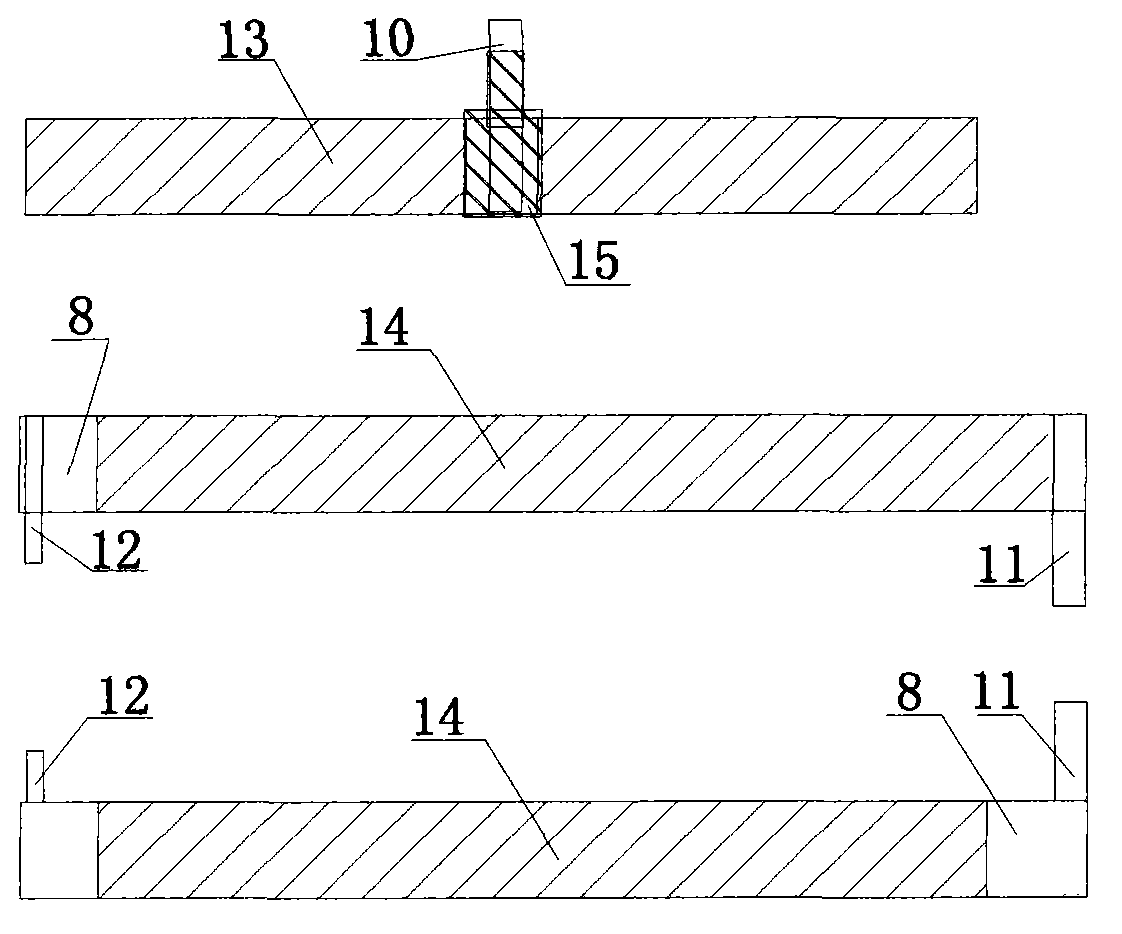

[0036] A method for preparing a nickel-cobalt lithium manganese oxide cylindrical high-rate battery, comprising the steps of:

[0037] Step 1: Preparation of positive electrode active material: mixing the following raw materials in parts by weight: 1 to 3 parts of binder, 92 to 95 parts of nickel-cobalt lithium manganese oxide, 1 to 3 parts of conductive carbon black, 1 1-3 parts of conductive graphite and 33-82 parts of N-methylpyrrolidone;

[0038] Step 2: Preparation of negative electrode active material: mixing the following raw materials in parts by weight: 92 to 95 parts of graphite, 1 to 3 parts of conductive carbon black, 3 to 5 parts of binder and 100 to 150 parts Deionized water;

[0039] Step 3: Preparation of positive electrode sheet 6: Coating the positive electrode active material prepared in step 1 on the inner and outer ring surfaces of the aluminum foil respectively, and then placing it in a tunnel oven at a temperature of 70°C to 130°C Drying for 2 minutes...

Embodiment 1

[0053] A method for preparing a nickel-cobalt lithium manganese oxide cylindrical high-rate battery, comprising the steps of:

[0054] Step 1: Prepare the positive electrode active material: including the following raw materials mixed according to parts by weight: 2 parts of polyvinylidene fluoride, 93 parts of nickel cobalt lithium manganate, 3 parts of conductive carbon black, 2 parts of conductive graphite and 55 parts of N - methylpyrrolidone;

[0055] Step 2: Prepare the negative electrode active material: including the following raw materials mixed according to parts by weight: 93 parts of graphite, 3 parts of conductive carbon black, 4 parts of binder and 120 parts of deionized water; the binder is: A mixture of 1% to 2% sodium carboxymethyl cellulose and 2% to 3% butadiene rubber, wherein 1% to 2% sodium carboxymethyl cellulose is 1.5 parts, 2% to 3% butadiene This rubber is 2.5 parts.

[0056] Step 3: Preparation of positive electrode sheet 6: Coating the positive e...

Embodiment 2

[0070] A method for preparing a nickel-cobalt lithium manganese oxide cylindrical high-rate battery, comprising the steps of:

[0071] Step 1: Prepare the positive electrode active material: it is prepared by mixing the following raw materials in parts by weight: 1 part of binder, 92 parts of nickel-cobalt lithium manganese oxide, 1 part of conductive carbon black, 1 part of conductive graphite and 33 parts of N-formazan Base pyrrolidone;

[0072] Step 2: Prepare the negative electrode active material: it is prepared by mixing the following raw materials according to parts by weight: 92 parts of graphite, 1 part of conductive carbon black, 3 parts of binder and 100 parts of deionized water;

[0073] Step 3: Preparation of positive electrode sheet 6: Coating the positive electrode active material prepared in step 1 on the inner and outer ring surfaces of the aluminum foil respectively, and then placing it in a tunnel oven at a temperature of 70°C to 130°C Drying for 2 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com