Spinning process of plate-made belt pulley and forming roller used for same

A spinning process, pulley technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve problems such as failure, poor elongation, material cracking, etc., to overcome low strength and low processing. performance, reduce product weight, stabilize the effect of spinning production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

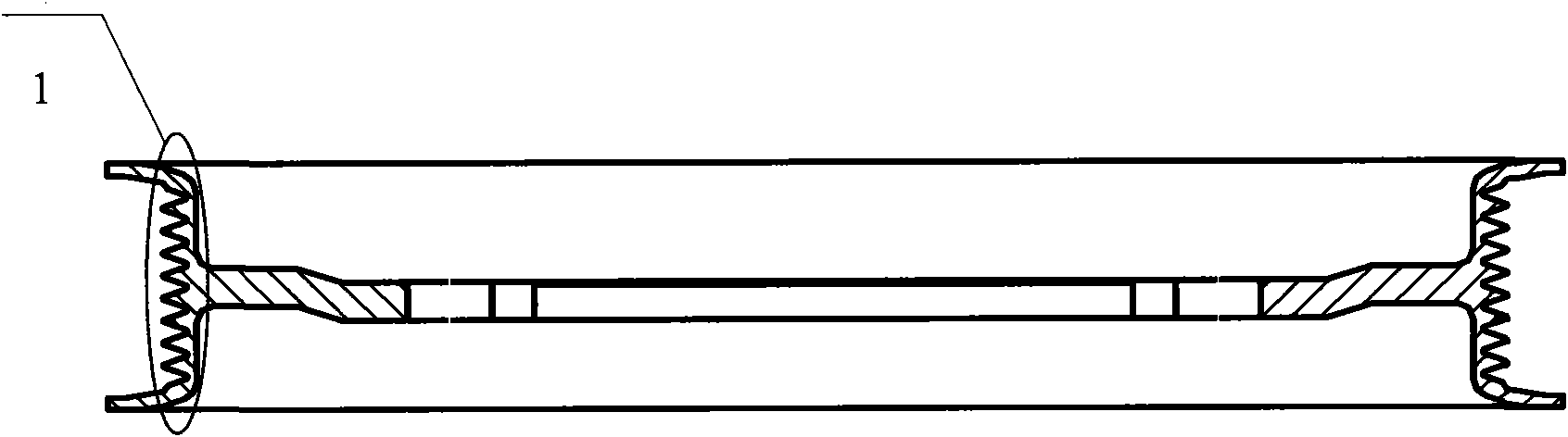

[0020] Such as figure 1 As shown, 1 is the groove shape to be processed. The product is a rotary part, with 9 grooves and multiple V-type crankshaft pulleys, with an outer diameter of φ211mm. The groove shape and the base metal are T-shaped symmetrical.

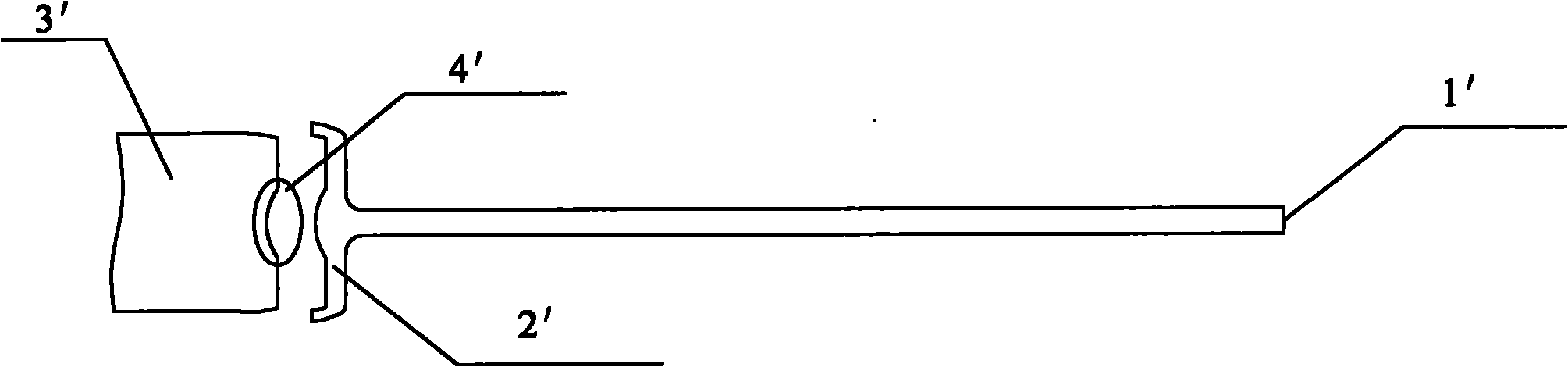

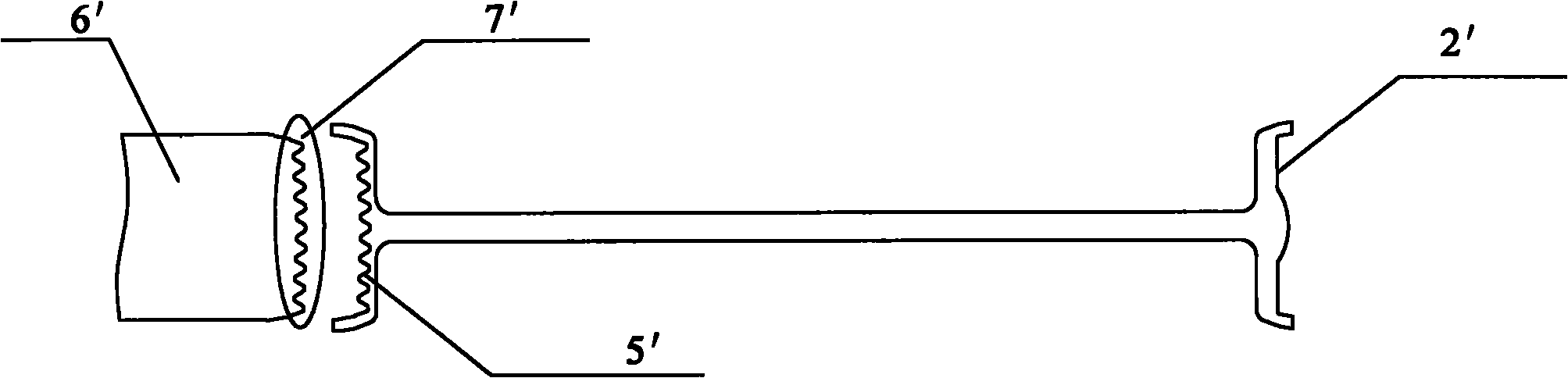

[0021] Such as figure 2 As shown, 1' is the shape of the base metal of the sheet metal before spinning. The base metal is an aluminum-magnesium alloy, which has higher strength than other aluminum alloys with elongation properties; In other states, it has higher elongation properties. 2' is the shape after step ① molding, 3' is the preformed rotary wheel, and 4' is the groove of the preformed rotary wheel 3'. The preforming rotary wheel 3' moves horizontally during work, and evenly piles up the base material to both ends along the center line. During this process, the flow of materials is extremely violent. Due to the equipment accuracy and the flatness of raw materials, the distribution of material flow will be uneven, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com