Self-healing type non-self-adhesive modified asphalt waterproof coiled material and preparation method thereof

A technology of modified asphalt and waterproof membrane, which is applied in the direction of building insulation materials, building components, buildings, etc. It can solve the problems of waterproof failure and self-repair, and achieve the effects of high waterproof guarantee, convenient construction and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

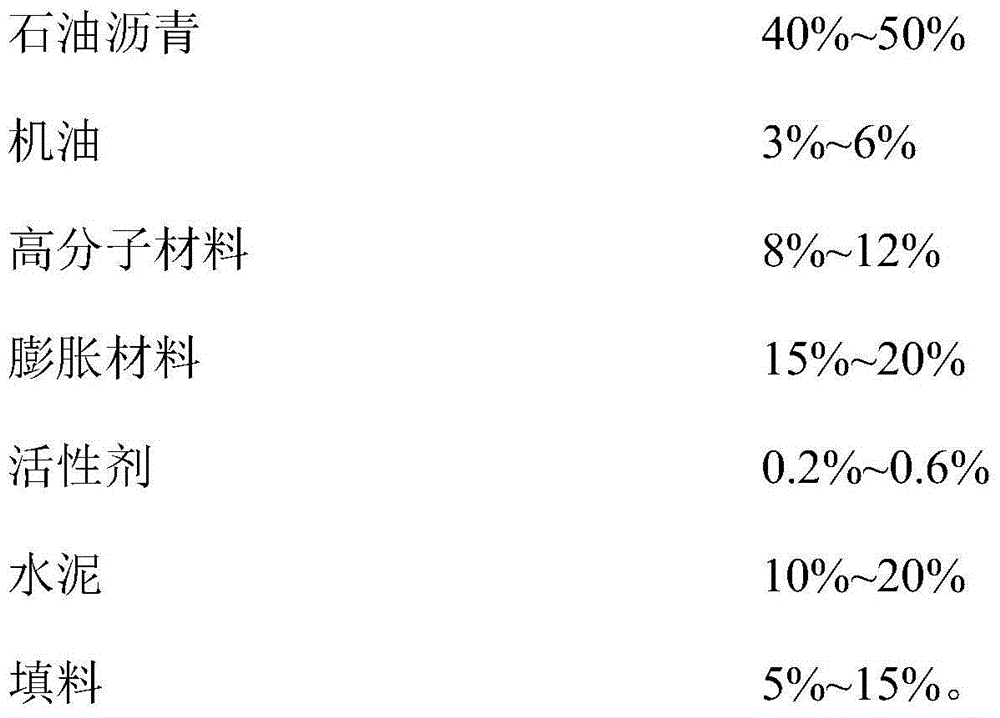

[0034] A self-healing non-self-adhesive modified bitumen waterproof membrane, the preparation of the coating material and the membrane forming process are as follows:

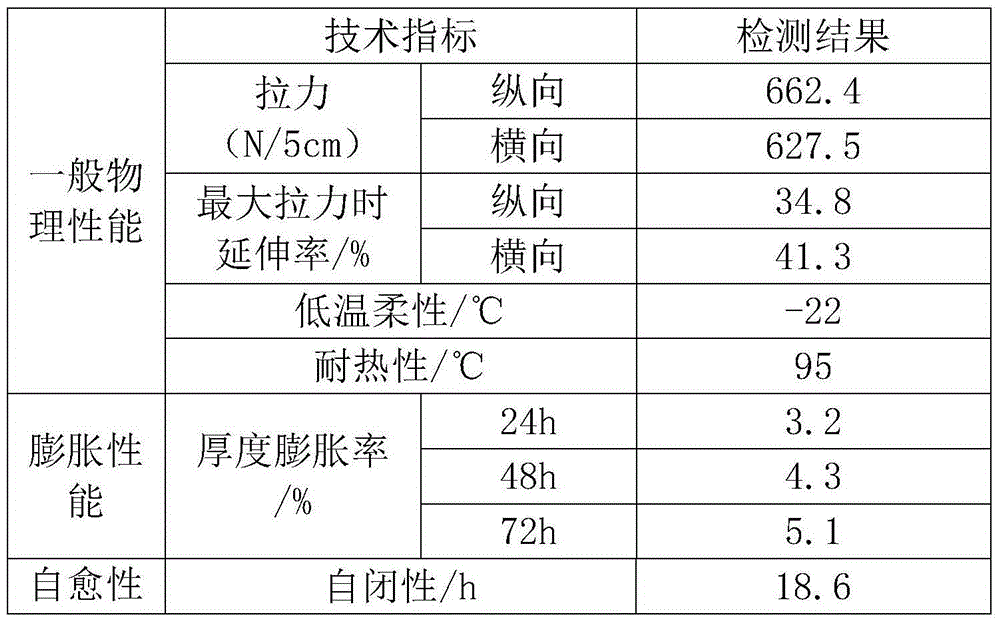

[0035] (1) Preparation of coating materials: Add 25kg of 10# petroleum asphalt, 20kg of 70# petroleum asphalt, 5kg of 46# mechanical oil, and 10.5kg of SBS styrene-butadiene rubber into the reaction kettle, heat to 210-220°C, 40-50r / min Stir at a constant speed for 2.2 hours to fully melt the SBS rubber, then add 18kg of sodium bentonite, 0.3kg of sodium dodecylbenzenesulfonate, 14kg of micro-expanded sulfoaluminate cement, 7.2kg of calcium carbonate filler, etc., and continue stirring for 0.5 to 1 hour , after fully mixing evenly, cool down to 185-192°C for use.

[0036] (2) Coil forming process: Put the coating material prepared in step (1) into a forming tank with heat preservation measures (the heat preservation measures of the forming tank are 200-210°C), and put 200g of polyester tire at 25m / min The spee...

Embodiment 2

[0041] A self-healing non-self-adhesive modified bitumen waterproof membrane, the preparation of the coating material and the membrane forming process are as follows:

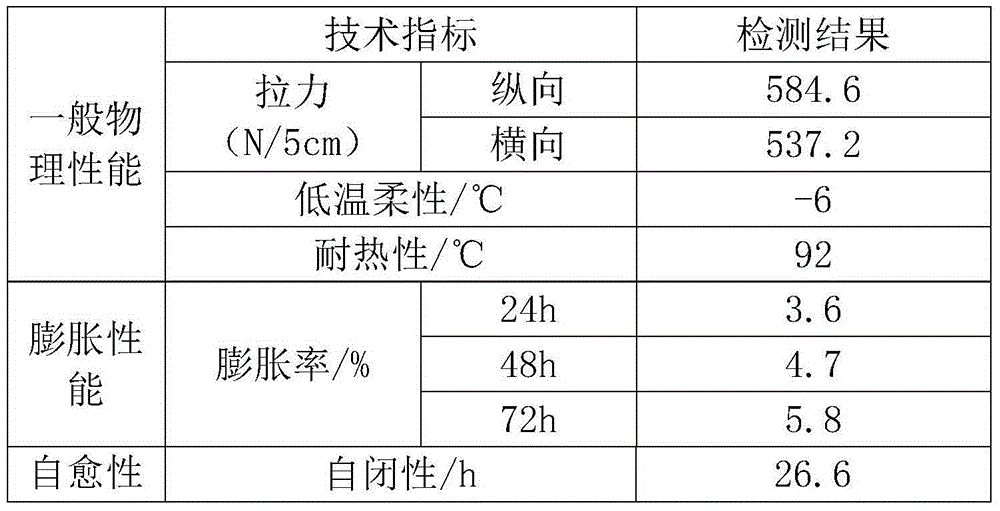

[0042] (1) Preparation of coating materials: Add 27kg of 30# petroleum asphalt, 15kg of 90# petroleum asphalt, 4.2kg of 32# mechanical oil, and 12kg of reclaimed rubber powder into the reaction kettle, heat to 220-230°C, 40-50r / min at a constant speed Stir for 2.5 hours to fully melt the reclaimed rubber powder, then add 15kg of potassium-based bentonite, 0.2kg of sodium dodecylbenzenesulfonate, 12kg of micro-expanded sulphoaluminate cement, 14.6kg of calcium carbonate filler, etc., continue stirring for 1 hour, and fully After mixing evenly, cool down to 190-195°C for use.

[0043](2) Coil forming process: Put the coating material prepared in step (1) into the forming tank with heat preservation measures (the heat preservation measures of the forming tank are 210-220 °C), and put the non-woven fabric-grid clot...

Embodiment 3

[0048] A self-healing non-self-adhesive modified bitumen waterproof membrane, the preparation of the coating material and the membrane forming process are as follows:

[0049] (1) Preparation of coating materials: Add 30kg of 10# petroleum asphalt, 18kg of 70# petroleum asphalt, 4.6kg of 46# mechanical oil, 8.4kg of APP random polypropylene, and 4.6kg of reclaimed rubber powder into the reaction kettle, and heat to 210~ 220°C, 40-50r / min, stirring at a constant speed for 2.4h to fully melt the APP and reclaimed rubber powder, then add 16kg of sodium bentonite, 3kg of calcium oxide, 0.4kg of sodium lauryl sulfate, and 10kg of micro-expansive sulphoaluminate cement , calcium carbonate filler 5kg, etc., continue to stir for 0.5~1h, after fully mixing, cool down to 190~195℃ for use.

[0050] (2) Coil forming: Put the coating material prepared in step (1) into the forming tank with heat preservation measures (the heat preservation measures of the forming tank are 210-220°C), and pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com