Guiderail device and method for pouring slope roof

A technology of guide rail device and sloping roof, which is applied in the processing of building materials, roofs, buildings, etc. It can solve problems such as flatness not meeting the construction accuracy requirements of the waterproof layer, concrete slipping, and vibration not being dense, so as to avoid construction quality Problems, prevention of slippage, effect of easy pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

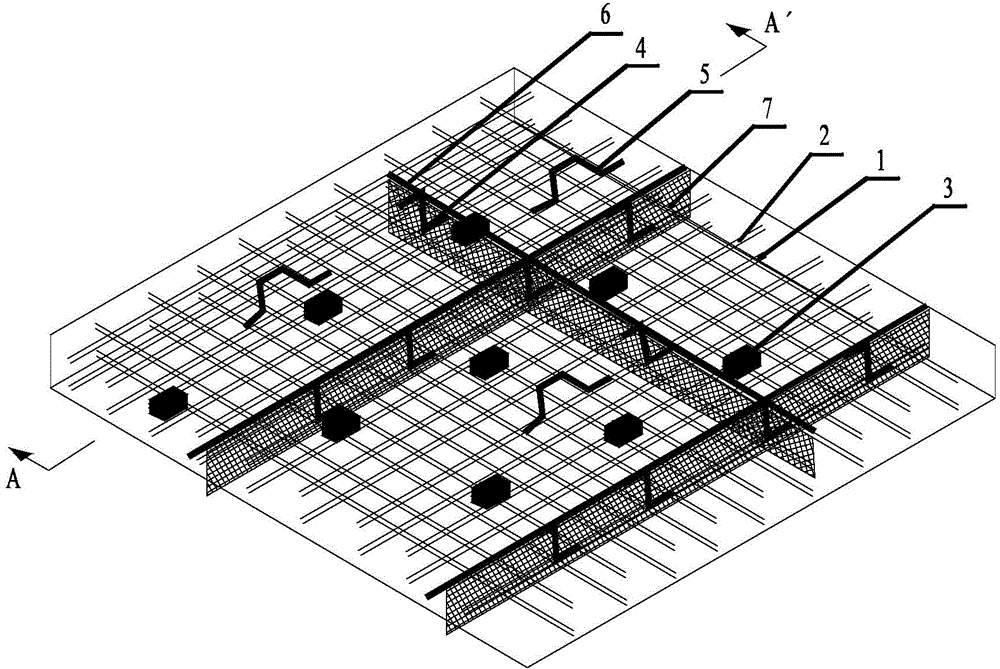

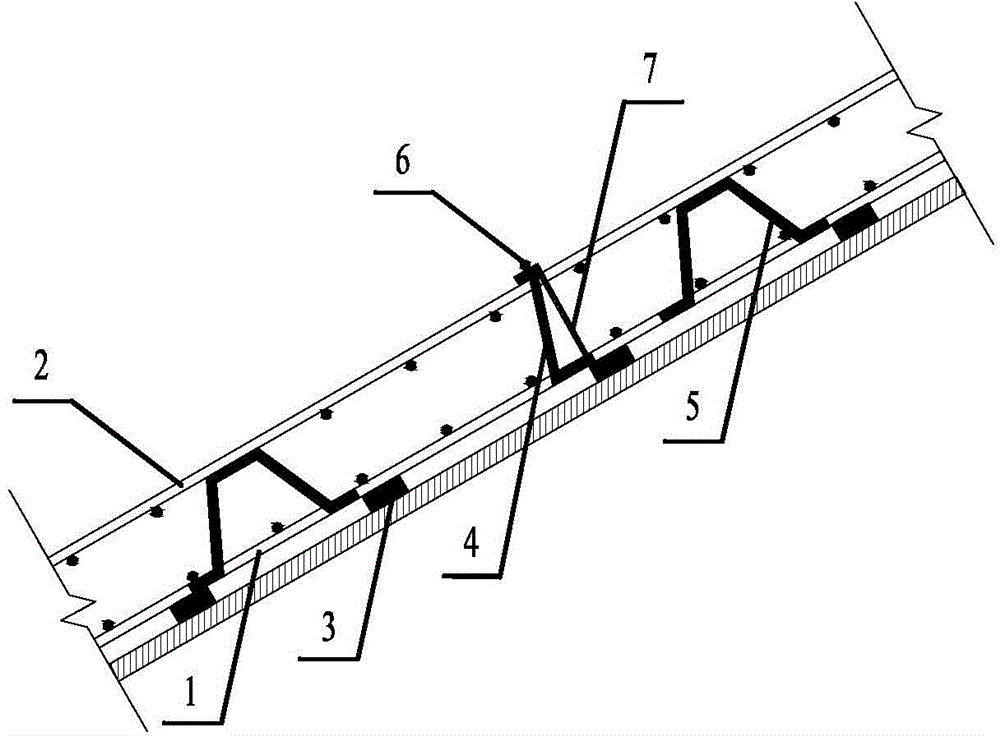

[0036] Such as figure 1 with figure 2 As shown, a guide rail device for pouring construction of a sloping roof includes a slab bottom steel bar 1 laid on the top surface of the sloping roof formwork, and a slab surface steel bar 2 arranged opposite to the slab bottom steel bar 1 is arranged above the slab bottom steel bar 1 . A plurality of pads 3 are arranged between the steel bars 1 at the bottom of the slab and the formwork of the sloping roof. The pads 3 are concrete blocks, which are used to carry the steel bars 1 at the bottom of the slab and form a sufficient protective layer specified in the design, and the adjacent pads 3 The spacing between them is 1m. A plurality of horse stool bars 5 are arranged between the bottom reinforcement 1 and the board surface reinforcement 2, and the plurality of horse stool bars 5 are arranged in a qu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com