Continuous casting stop-casting blank tail discharge and top sealing method

A technology of continuous casting and billet tail, applied in the field of continuous casting stop casting billet tail and capping, can solve the problems of high cooling strength, reduced yield, deep billet vibration marks, etc., to reduce the length of the billet and improve the surface quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

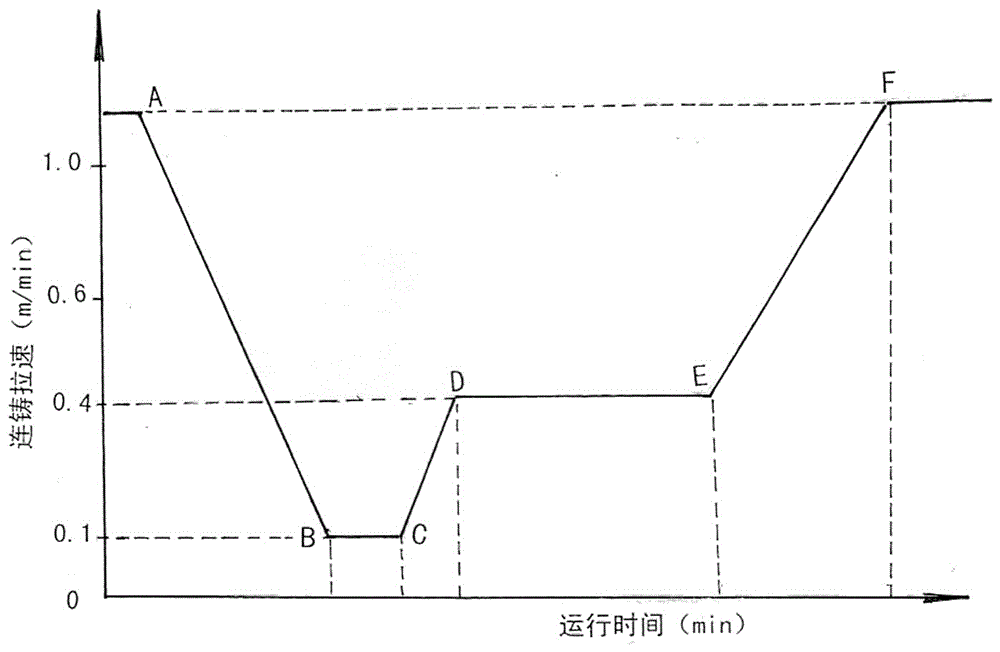

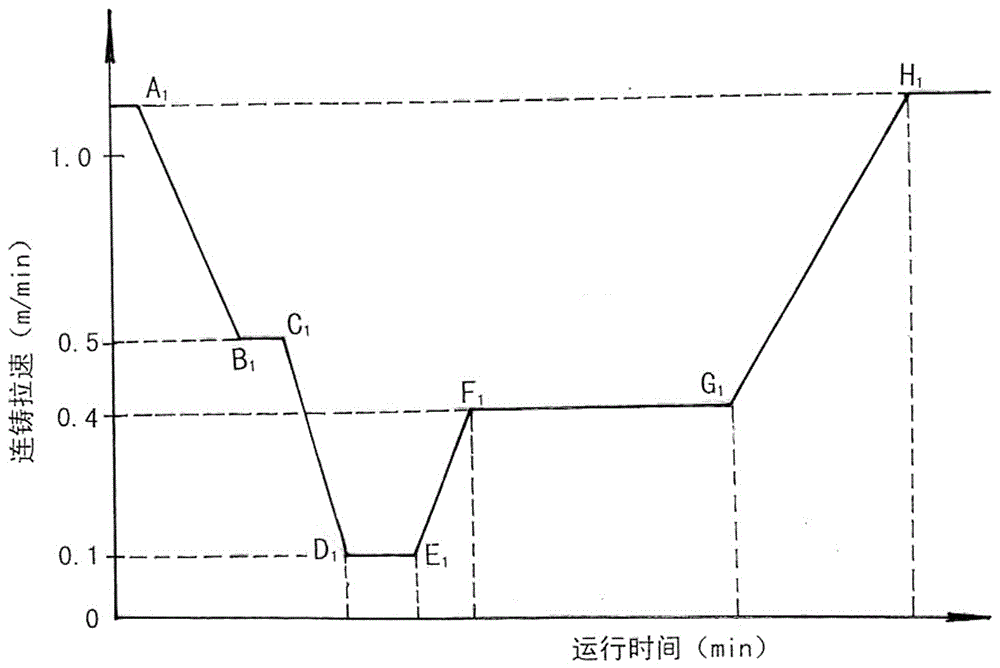

[0016] The main technical method (that is, the technical means) of the present invention is: after the continuous casting of molten steel is stopped and the slab is tailed out, the casting speed of the continuous casting is controlled within 0.09-0.11m / min, and the cooling rod is put into the crystallizer at the same time Afterwards, the continuous casting casting speed increased to 0.38-0.42m / min for a time ≥ 1.5min (ie ≥ 90s), and then 0.45-0.55m / min 2 The acceleration increases the continuous casting casting speed to the typical casting speed (≥1.0m / min). When the tail of the continuous casting slab reaches the 7th to 8th section of the straightening section, the continuous casting casting speed is reduced to 1.0m / min. Through the above technical means, the cut tail length of the continuous casting slab can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com