Clutch system

A clutch device and locking technology, applied in the direction of clutch, friction clutch, mechanical drive clutch, etc., can solve the problem of reducing the separation force of the clutch device, and achieve the advantages of reduced weight and installation space, simple and cheap, and enhanced extrusion force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

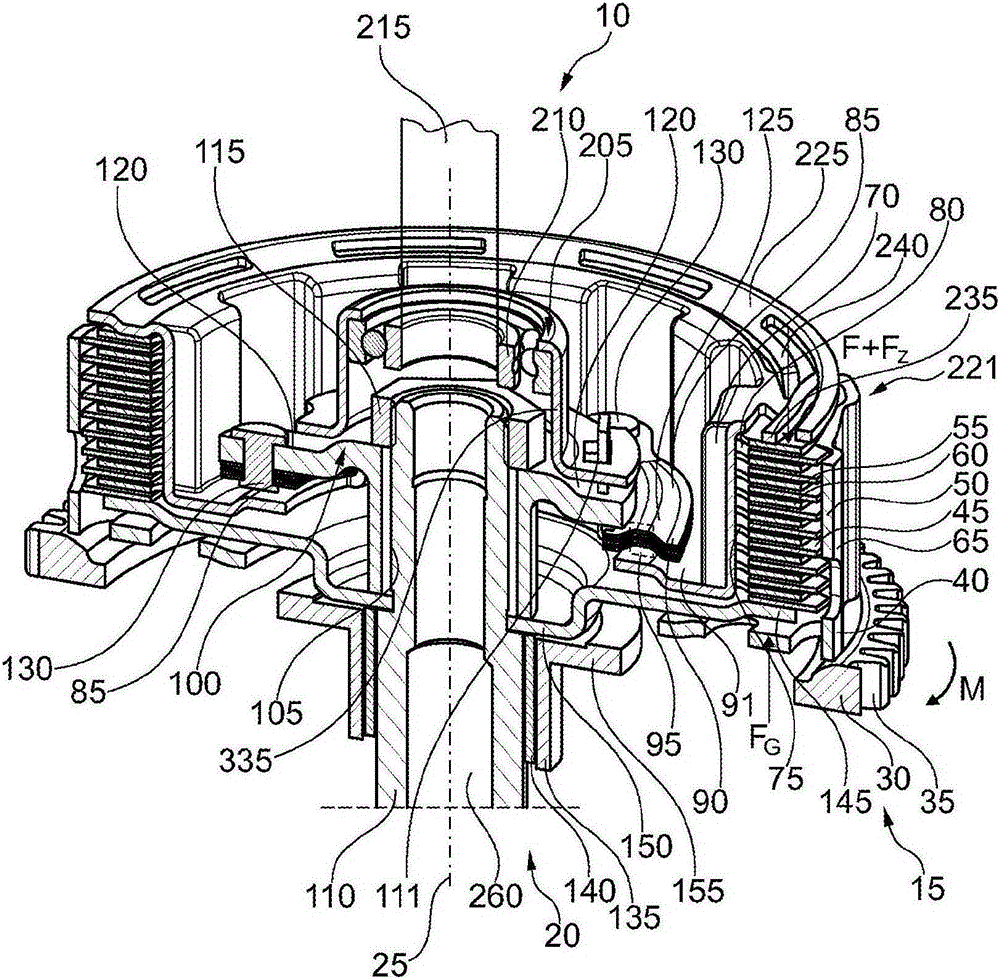

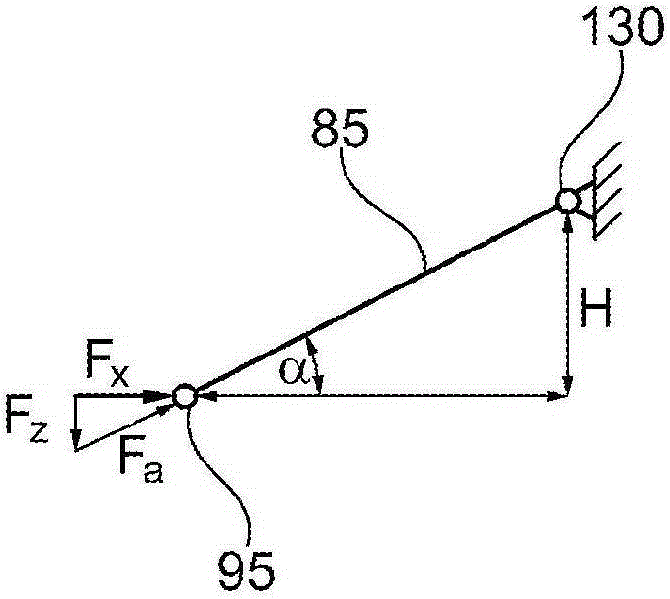

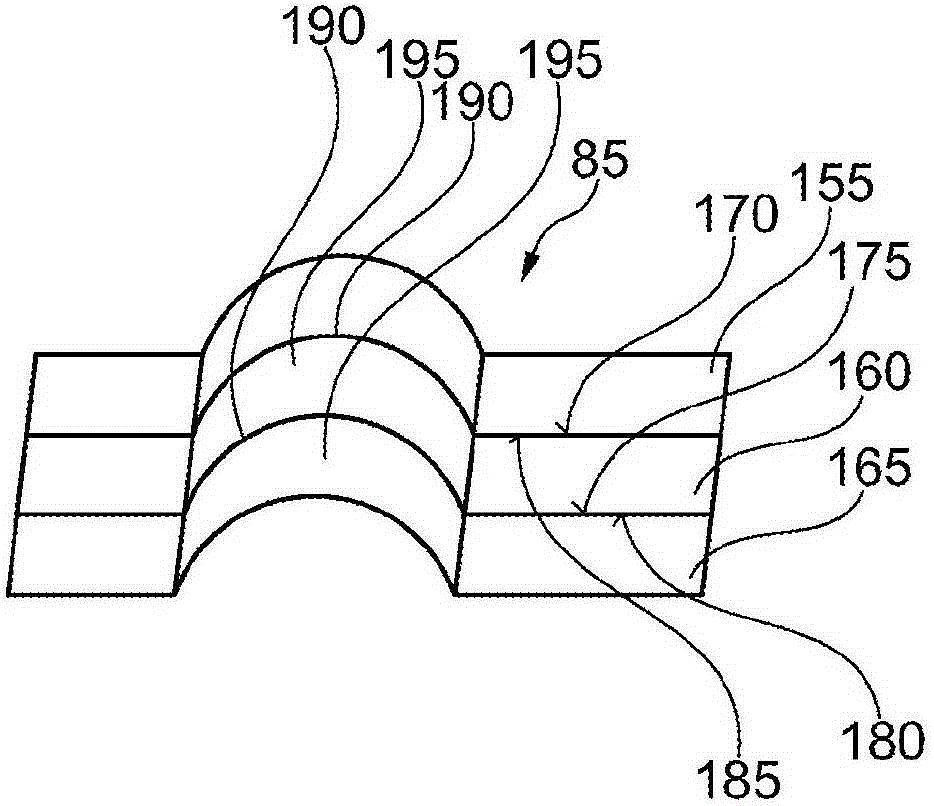

[0038] figure 1 A perspective half-sectional view of the clutch device 10 according to the first embodiment is shown. figure 2 shown in figure 1 A schematic illustration of the spring element 85 of the clutch device 10 shown in . image 3 shown in figure 1 A cross-sectional view of the clutch device 10 shown in . Figure 4 show Figures 1 to 3 A detailed view of the perspective cross-sectional view of the clutch device 10 shown in . Figure 5 A perspective sectional view of a clutch device according to a second embodiment is shown. Figure 6 A perspective cross-sectional view of the clutch device 10 is shown, and, Figure 7 and Figure 8 Shown with braced figure 1 A perspective illustration of the clutch device 10 is shown in . Figure 8 shown in Figure 7 A longitudinal sectional view of the clutch device 10 shown in . For ease of understanding, in the following the Figures 1 to 8 Let's explain together.

[0039] The clutch arrangement 10 includes an input side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com