Press filter

A filter press and filter plate technology, applied in the field of filter presses, can solve the problems of small extrusion force, low dehydration efficiency, inability to achieve high solid content, etc., and achieve the effect of large extrusion force and fast cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

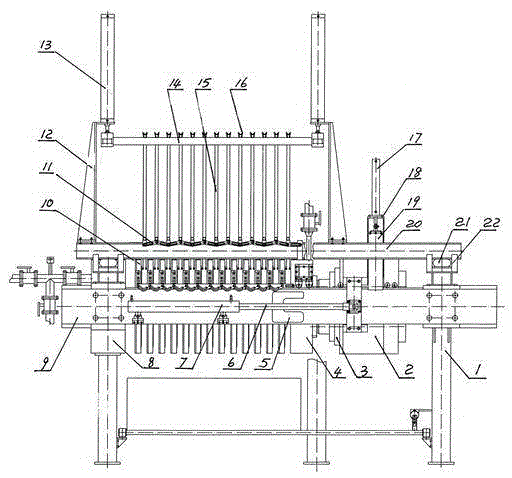

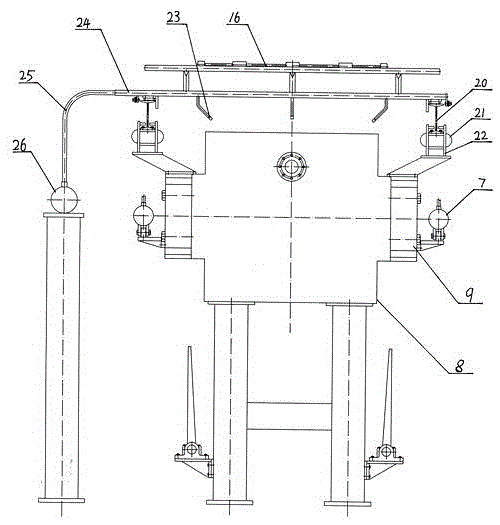

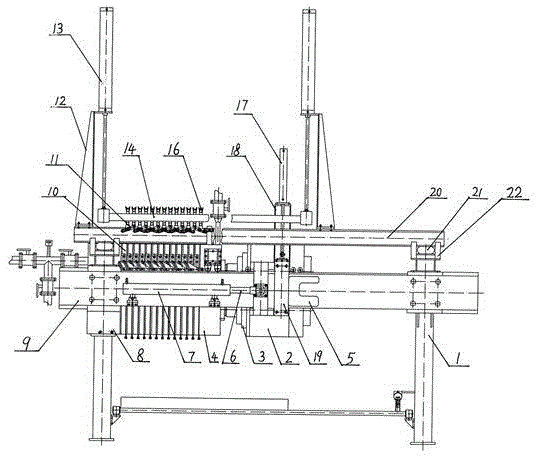

[0008] In order to improve the dryness of the sludge, a hydraulic cylinder is used to squeeze the sludge, and the squeezing force can reach 60kg / cm 2 , The dryness of the sludge can reach more than 50%. Existing main hydraulic cylinder support is fixed on the main girder, for the quick-open variable capacity filter press, the stroke of main hydraulic cylinder 3 will lengthen a lot, and the cost of this hydraulic cylinder is huge. The main hydraulic cylinder base 2 of the present invention adopts a movable structure, and the left ends of the front and rear two main beams 9 are respectively fixed on the front and rear sides of the thrust plate 8, and the right ends of the front and rear two main beams are respectively fixed on the right bracket. 1, the guide rail 35 is fixed on the upper surface of the front and rear main beams, and the guide rollers 27 and flat rollers 28 of the main hydraulic cylinder base are placed on the guide rails and fixed on the base The piston rod of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com