Hot spinning bottom-finishing method of seamless gas cylinder by positive roller

A technology of hot spinning and gas cylinders, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of low extrusion force and high price in the fusion zone, and achieve the effect of reducing equipment cost and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

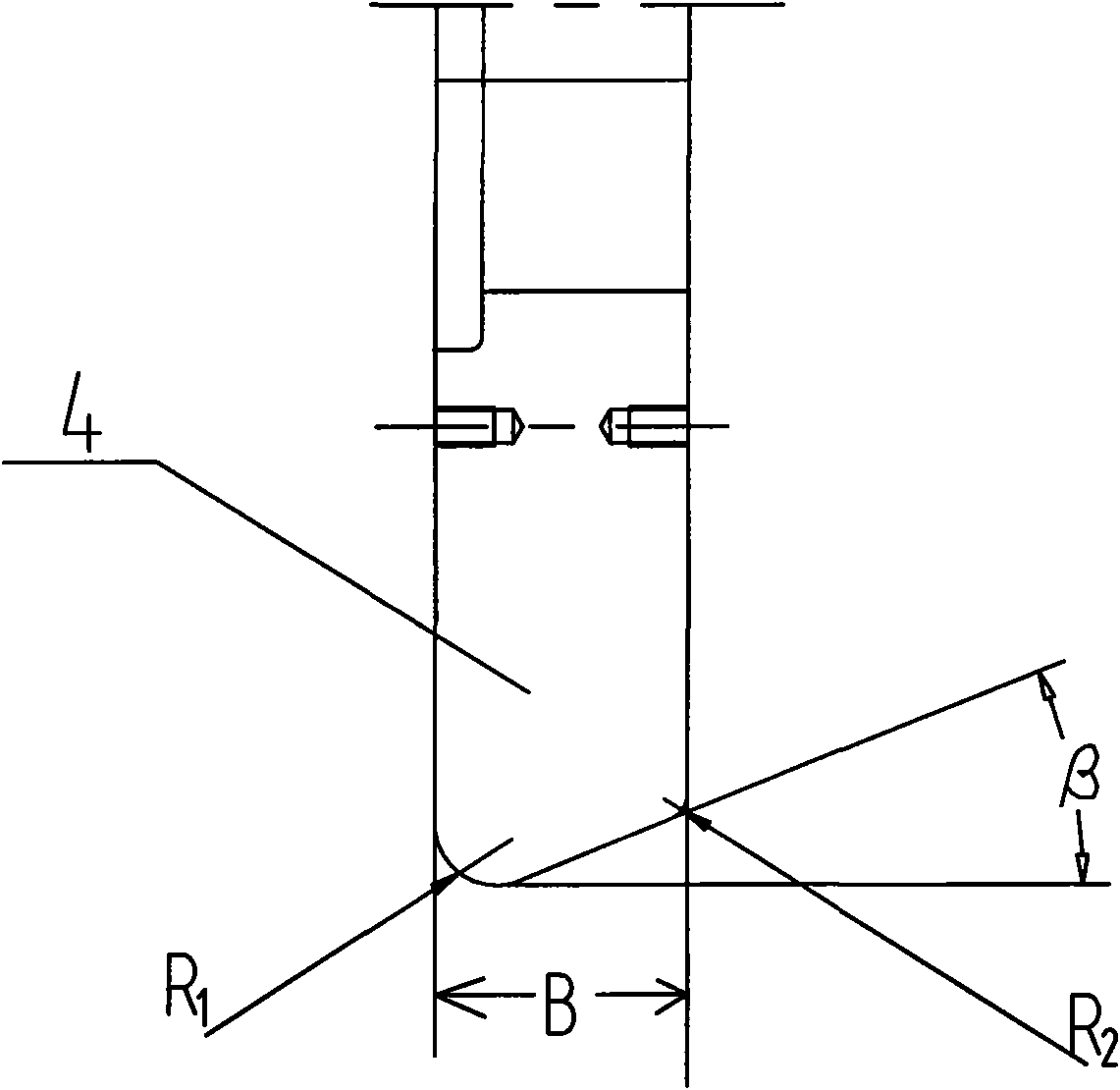

[0037] The structural parameters of the rotary wheel 4 used are: the rotary wheel width B=60mm, the angle β between the working slope and the rotary wheel axis line=16°, the fillet radius R at the lower end of the working slope 1 =9mm, the fillet radius R of the high end of the working slope 2 = 6 mm.

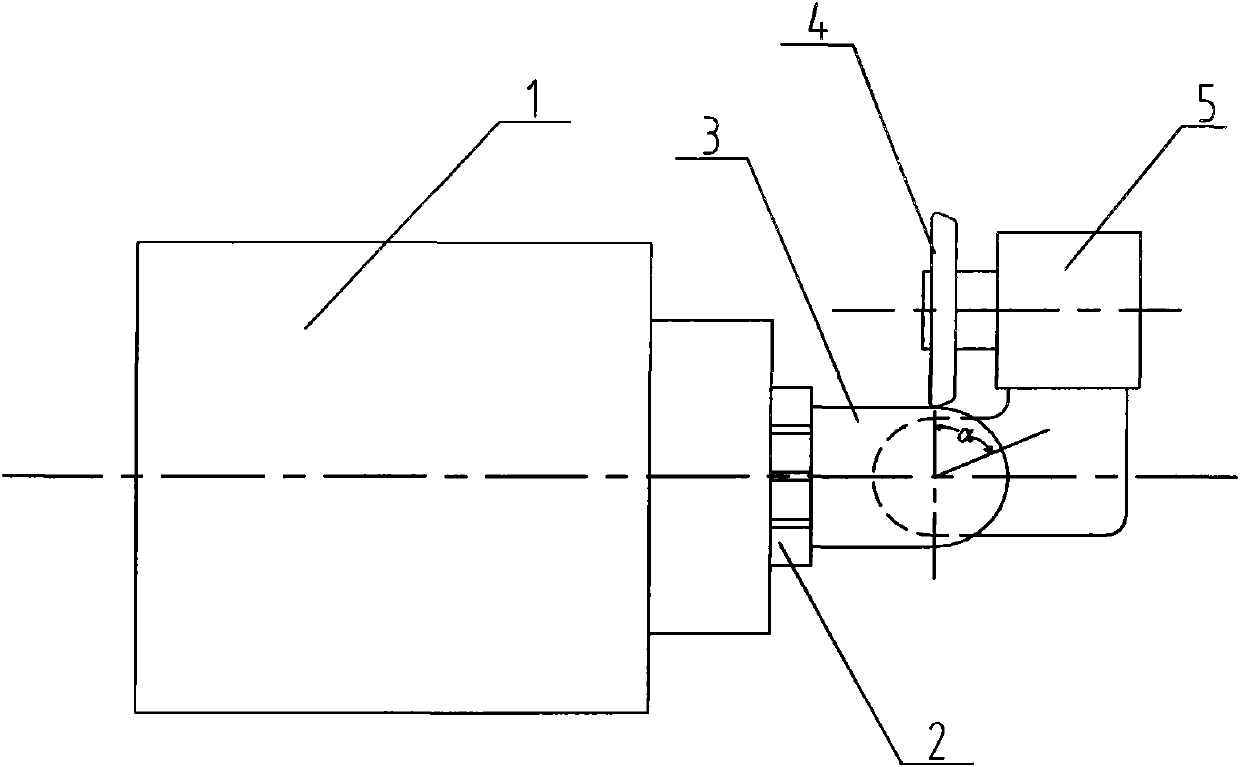

[0038] For Φ356mm×7.7mm, 80-liter ISO9809-1 compressed natural gas cylinders for automobiles, the GL425 CNC rotary wheel hot spinning machine produced by Sichuan Deyang Tellhow Technology Co., Ltd. is used. The process of spinning and closing the bottom is as follows:

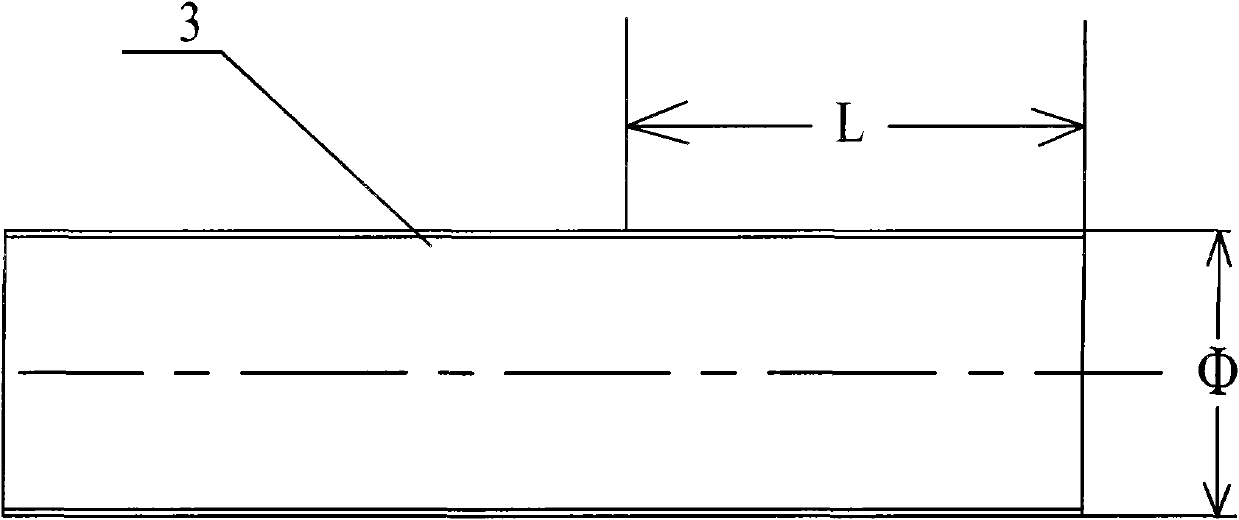

[0039] 1) Steel pipe heating: the steel pipe 3 is automatically fed into an intermediate frequency heating furnace and heated to 1080°C, and the heating length of the bottom section of the steel pipe 3 is L=420mm. The relationship between the diameter Φ of the steel pipe 3 and the heating length L is as follows image 3 shown.

[0040]2) Sealing and spinning: Turn on the automatic heat supplement gun to suppl...

Embodiment 2

[0047] The structural parameters of the rotary wheel 4 used are: the rotary wheel width B=70mm, the angle β between the working slope and the rotary wheel axis line=25°, the fillet radius R at the lower end of the working slope 1 =20mm, the fillet radius R of the high end of the working slope 2 = 12 mm.

[0048] For the Φ406mm×6.6mm, 100-liter GB24160 ring-wound gas cylinder liner, the GL425 CNC rotary hot spinning machine produced by Sichuan Deyang Tellhow Technology Co., Ltd. is used. The process of spinning and closing the bottom is as follows:

[0049] 1) Steel pipe heating: the steel pipe 3 is automatically fed into an intermediate frequency heating furnace and heated to 1080°C, and the heating length of the bottom section of the steel pipe 3 is L=480mm. The relationship between the diameter Φ of the steel pipe 3 and the heating length L is as follows image 3 shown.

[0050] 2) Sealing and spinning: Turn on the automatic heat supplement gun to supplement the heat of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com