Mould of pure titanium equal channel angular extrusion and process method

A technology of equal channel and angle extrusion, which is applied in the direction of metal extrusion dies, can solve the problems of increased mold structure complexity, pressure head bending, press tonnage increase, etc., to achieve easy lubrication and troubleshooting, and mold structure Simplicity and the effect of improving mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

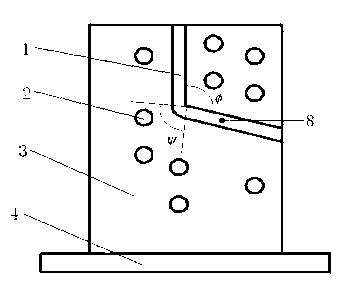

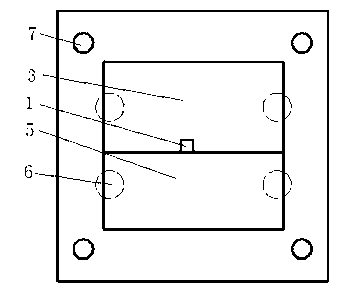

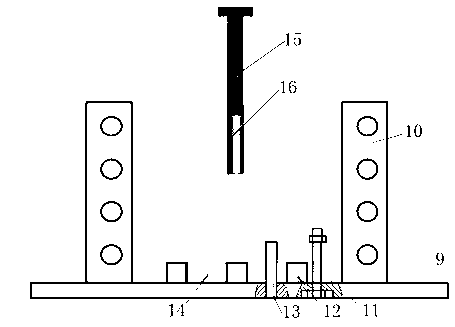

[0029] Please refer to Figure 1 to Figure 2 As shown, the mold of pure titanium equal channel angular extrusion of the present invention adopts the design of the integral die, that is, the die main body 3 and the die base 4 of the die are processed as a whole, and the die is arranged on a pad with heat insulation function plate 9 and fix it with fastening bolts and nuts 11. Whole die is made of two parts, and a part is the die main body 3 that contains isometric angle channel 1, and another part is the die cover plate 5 that contains a side of isometric angle channel 1 (such as figure 2 shown), and the two parts are fastened by high-strength bolts and nuts (not shown). The die main body 3 containing the channel part is the main force-bearing part, and this part is integrated with the die base 4. Such a structure increases the rigidity of the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com