Centrifuging device and sludge dehydrating method

A technology for centrifugal separation and sludge, applied in centrifuges, centrifuges with rotating drums, dewatering/drying/concentrating sludge treatment, etc., to achieve the effect of low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

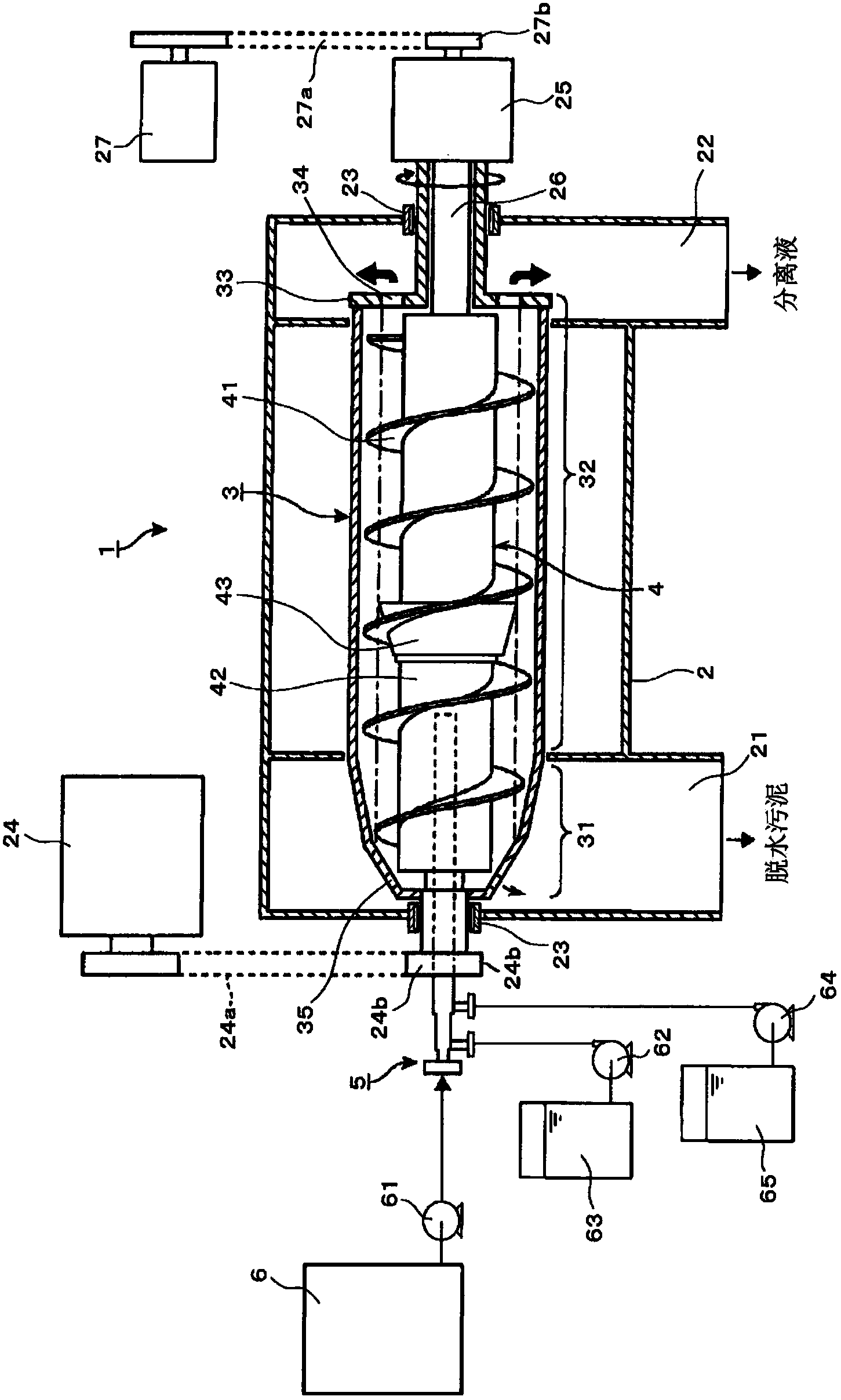

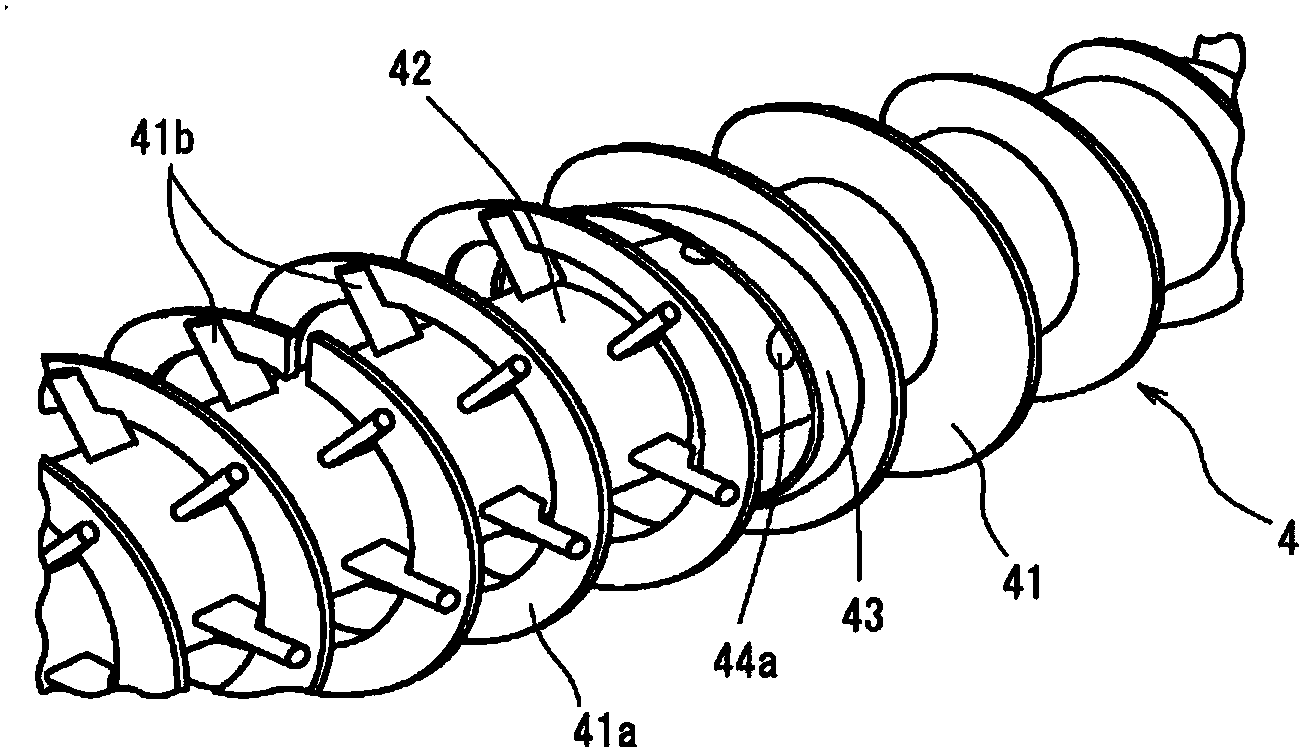

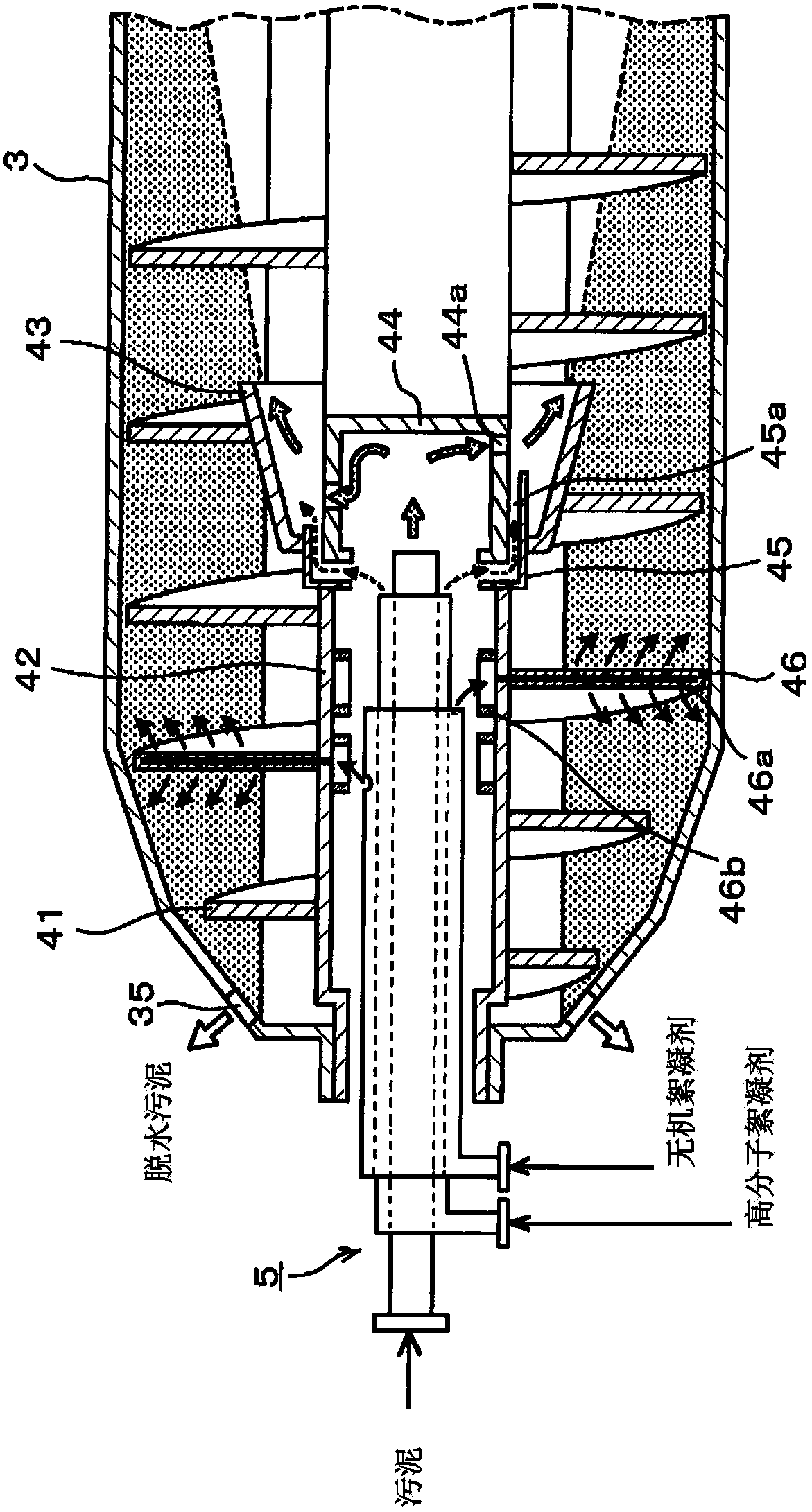

[0049] Taking a horizontal decanter as an example, the centrifugal separation device according to the first embodiment of the present invention will be described. like figure 1 As shown, the decanter 1 of this embodiment includes: a housing 2 with a dewatered sludge outlet 21 and a separation liquid outlet 22 respectively formed below; a drum 3 arranged in the housing 2 and formed as a drum; And the screw conveyor 4 as a conveying unit of the separated sludge in the drum 3 . The cylinder 3 is supported by a bearing structure 23 such as a bearing attached to the casing 2, and the screw conveyor 4 is supported by a conveyor bearing (not shown), and the cylinder 3 and the screw conveyor 4 are each independently rotatable around a horizontal axis.

[0050] The power of the driving motor 24 as the driving structure is transmitted to the pulley 24b on the side of the cylinder 3 through the transmission belt 24a, so that the cylinder 3 rotates at a certain rotational speed, and the ...

no. 2 approach )

[0077] Next, a horizontal decanter will be described as an example of a centrifugal separator according to a second embodiment of the present invention. like Figure 6 As shown, the decanter 1 of the present embodiment is provided with a new disk-shaped member 7 as a member for adding an inorganic flocculant, which is different from the first embodiment in which the screw blade 41 also serves as a member for adding an inorganic flocculant. Other structures may be the same as those of the first embodiment. Therefore, the same structures are assigned the same reference numerals, and detailed description thereof will be omitted.

[0078] The disc-shaped member 7 as an adding member is a disc-shaped member, and is provided on the outer periphery of the main body portion 42 of the screw conveyor 4 so as to be concentric with the rotation shaft. The disk-shaped member 7 is the same as the helical blade 41 of the first embodiment, and has a hollow structure inside, and forms the fl...

no. 3 approach )

[0081] Next, a horizontal decanter will be described as an example of a centrifugal separator according to a third embodiment of the present invention. like Figure 7 As shown, the decanter 1 of this embodiment differs from the second embodiment in that a nozzle member 8 is provided instead of the disk member 7 . Other structures may be the same as those of the first and second embodiments. Therefore, the same structures are assigned the same reference numerals, and detailed description thereof will be omitted.

[0082] The nozzle member 8 as an adding member is, for example, a pipe whose cross section is circular (see the cross-sectional view), and extends radially from the main body portion 42 of the screw conveyor 4 . The nozzle members 8 may not only be arranged in two phases of 0° and 180°, but may also be arranged in only one phase. Alternatively, they may also be arranged radially (for example, at intervals of 90°) along the radial direction of the screw conveyor 4 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com