Thermal viscosity loss pressure-sensitive adhesive, thermally peelable adhesive tape and preparation methods of thermal viscosity loss pressure-sensitive adhesive and thermally peelable adhesive tape

A thermal peeling tape, sticking and pressing technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., to achieve the effect of improving thermal peeling performance, preventing breakage and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with example the present invention is described in further detail.

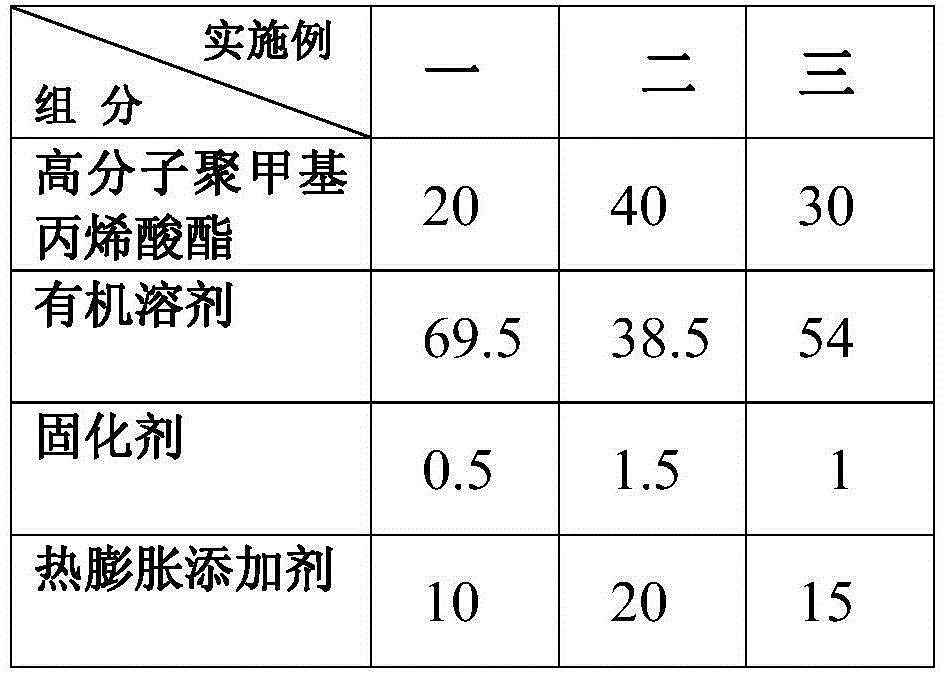

[0018] A heat-losing pressure-sensitive adhesive proposed by the present invention is prepared from the following raw materials in percentage by weight: 20.0%-40.0% of polymer polymethacrylate, 69.5%-38.5% of organic solvent, and 0.50% of curing agent ~1.50%, thermal expansion additive 10.0%~20.0%. Wherein, the solid content of the heat-losing pressure-sensitive adhesive is 20%-40% by weight.

[0019] According to the needs, the heat-losing pressure-sensitive adhesive can be made with different proportions of components. For example, the following examples can be used:

[0020]

[0021] The polymer polymethacrylate is at least a mixture of two raw materials of polymethyl methacrylate, polyethyl methacrylate and polybutyl methacrylate. The organic solvent is at least a mixture of two raw materials in toluene, ethyl acetate and butanone. The curing agent is at least one of isoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com