Method for cutting base plate by laser and laser cutting equipment

A laser cutting and substrate technology, applied in the field of laser cutting substrates and laser cutting equipment, can solve problems such as single cutting path, inability to correspond to special-shaped cutting, and fixed cutting sequence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

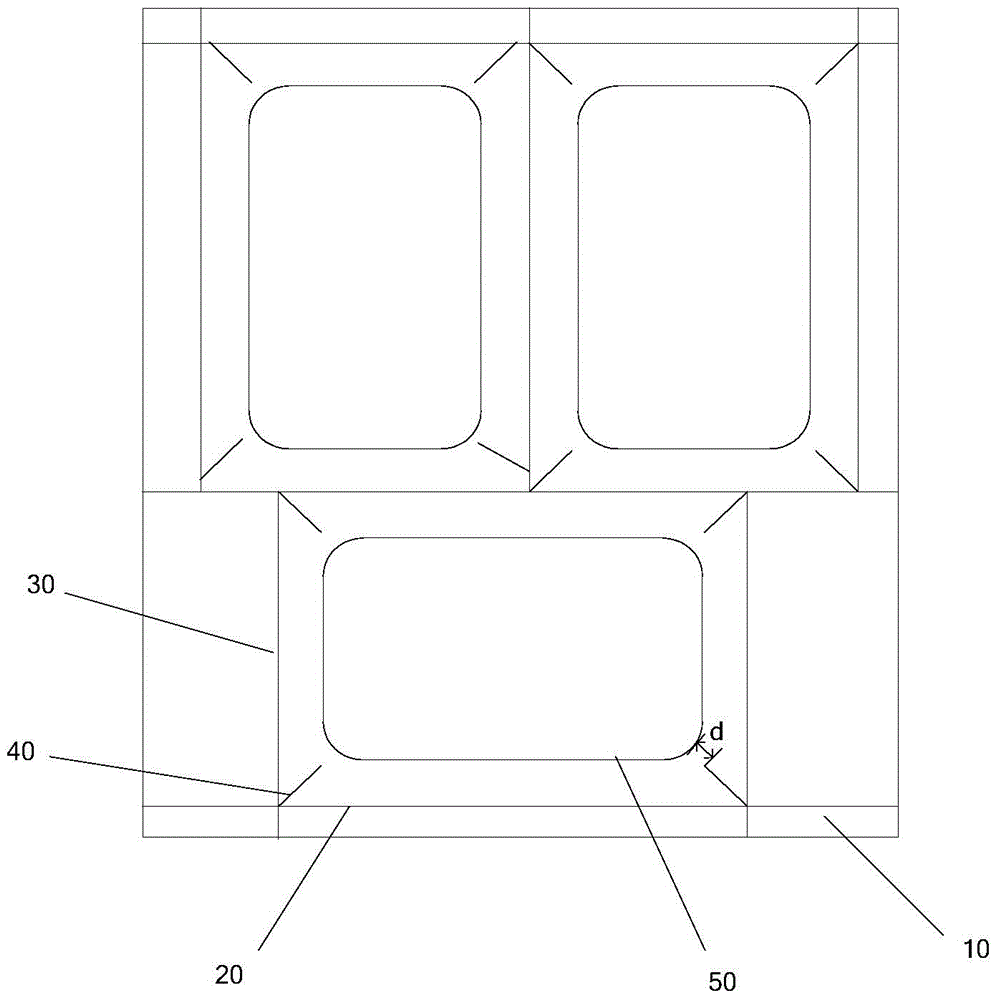

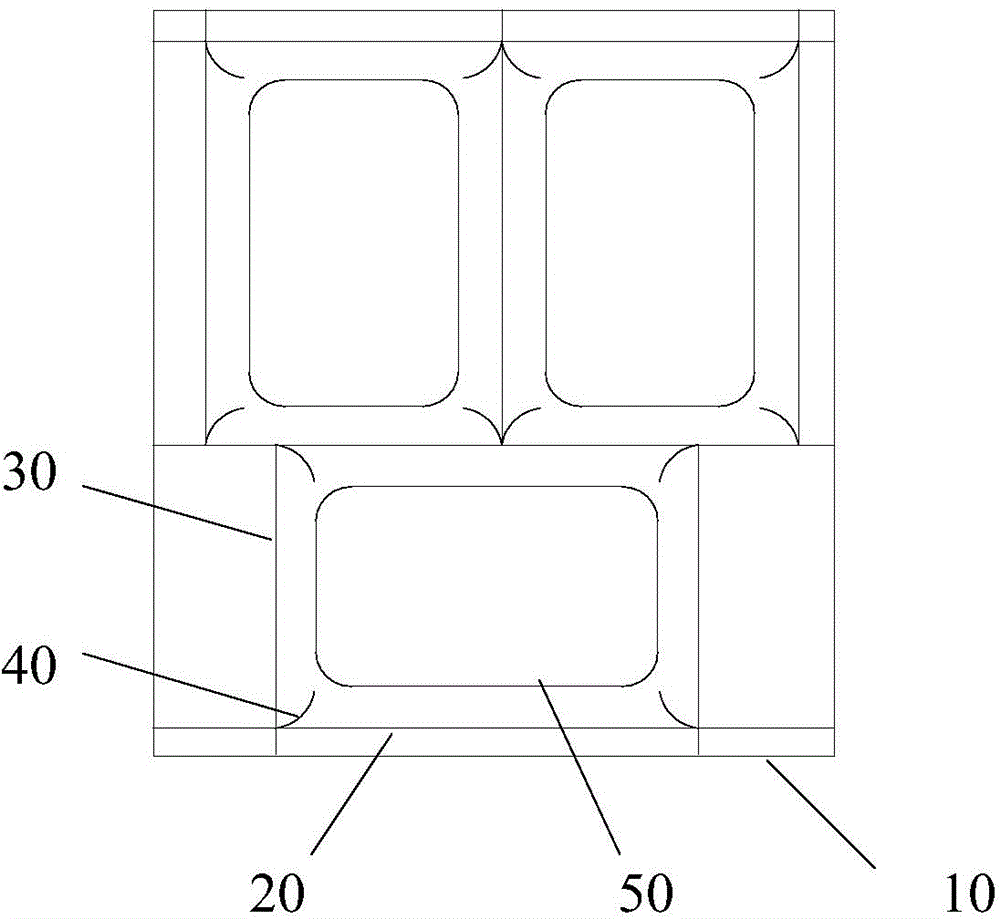

[0034] In order to increase the stress failure force point during substrate cutting, improve the effect of substrate cutting, and reduce the situation of substrate cracking. The embodiment of the present invention provides a laser cutting substrate method and laser cutting equipment. In the technical solution of the embodiment of the present invention, by adding an auxiliary splitting line, the effect of cutting out the irregular shape when laser cutting the substrate is improved, and the effect of substrate cutting is improved. , to improve the cracking of the substrate. In order to make the object, technical solution and advantages of the present invention clearer, the following non-limiting examples are taken as examples to further describe the present invention in detail.

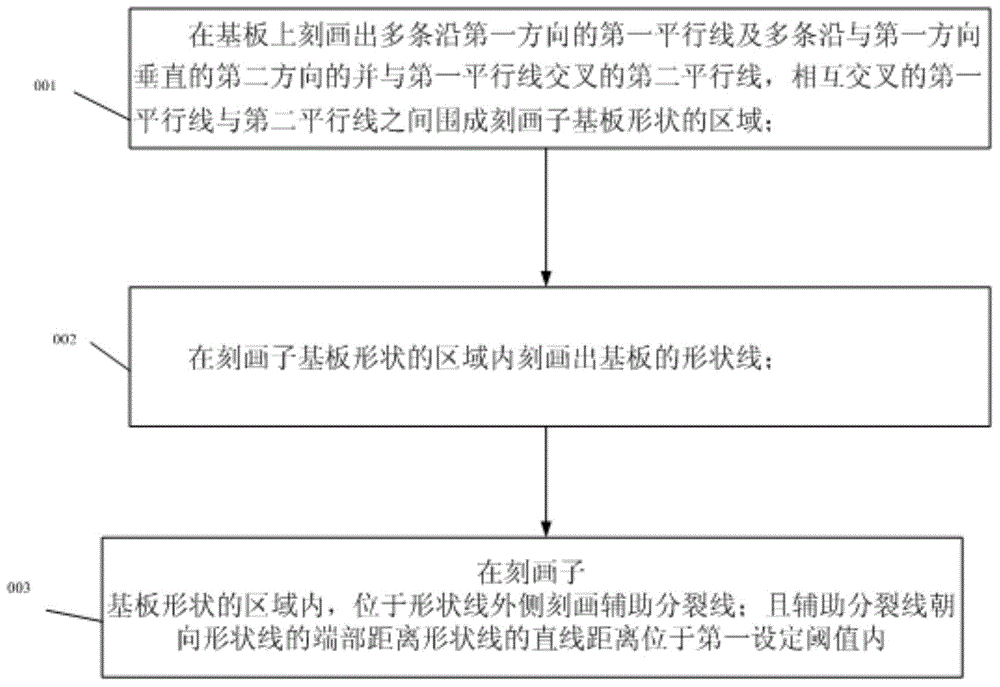

[0035] The invention provides a method for laser cutting a substrate, the method comprising the following steps:

[0036] On the substrate, a plurality of first parallel lines along a first direction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com