Current collector of liquid flow battery and liquid flow battery

A liquid flow battery and current collector technology, applied in battery electrodes, electrode carriers/current collectors, fuel cells, etc., can solve the problems of easy detachment of electrode mats, high cost, and large contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

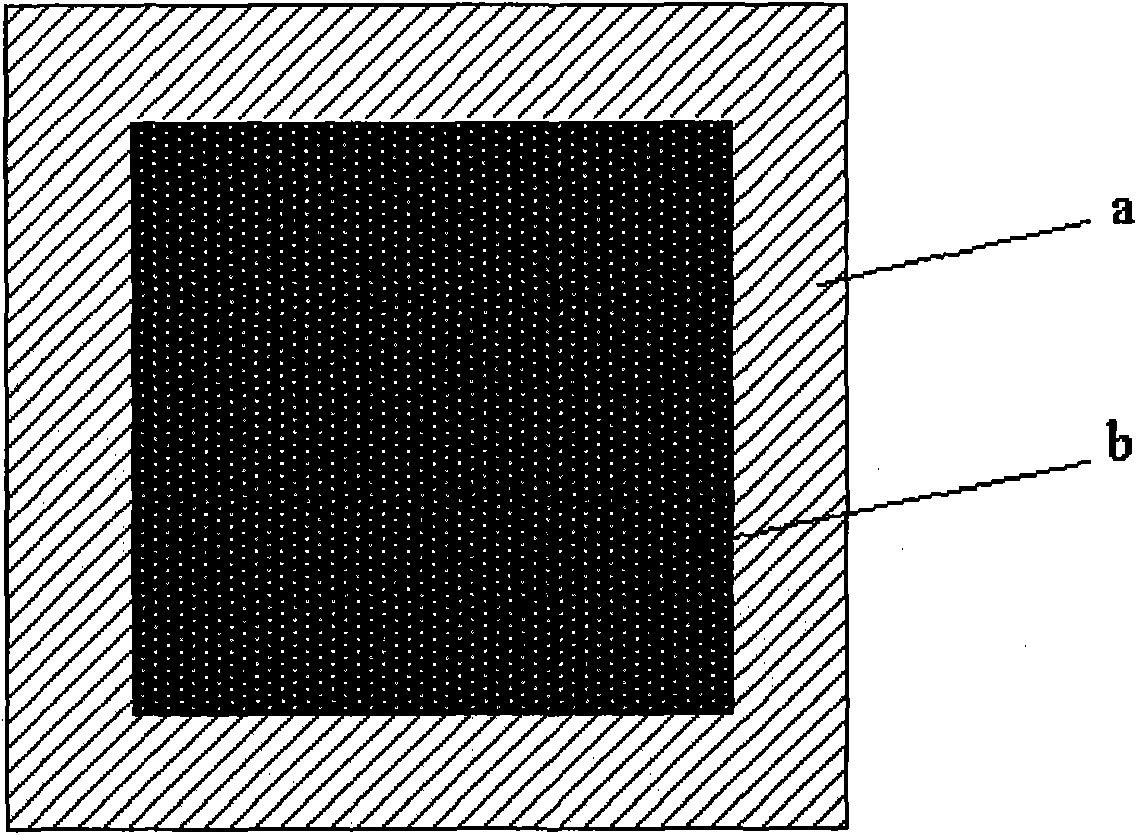

[0021] The preparation method of the current collector provided by the invention comprises hot pressing a graphite plate on the surface of a conductive plastic plate. The hot pressing can be performed using various conventional hot pressing machines, for example, a SYR-100T hot pressing machine from Dongguan Shangyu Oil Pressure Machinery Factory can be used. The temperature of hot pressing can be 200-500°C, preferably 320-400°C; the pressure of hot pressing can be 50-250Kg / cm 2 , preferably 150-200Kg / cm 2 , the time of hot pressing can be 5-60 minutes, preferably 25-45 minutes.

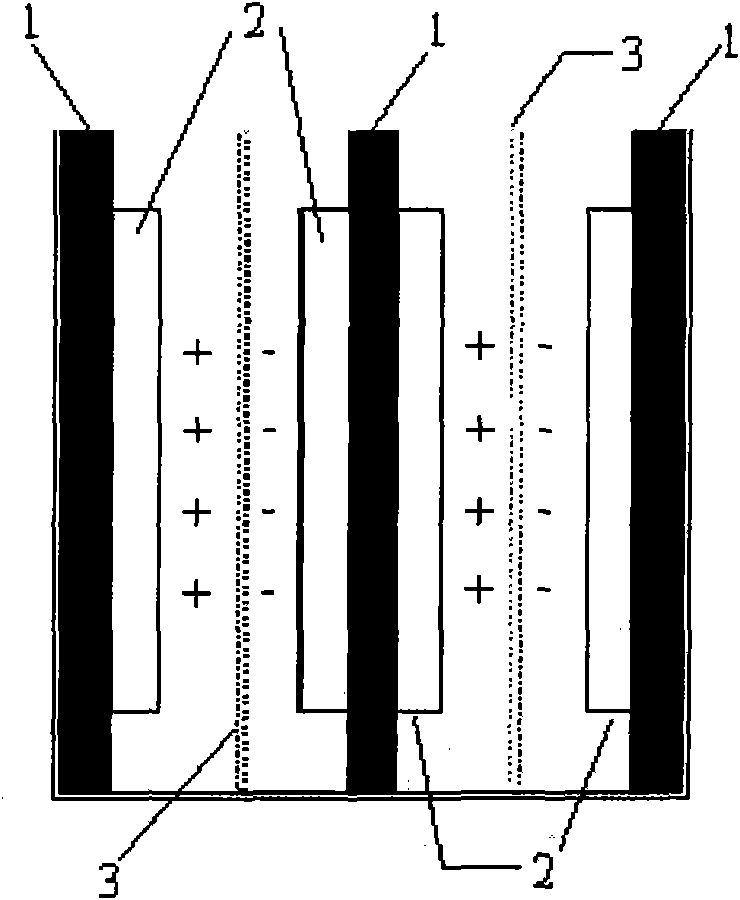

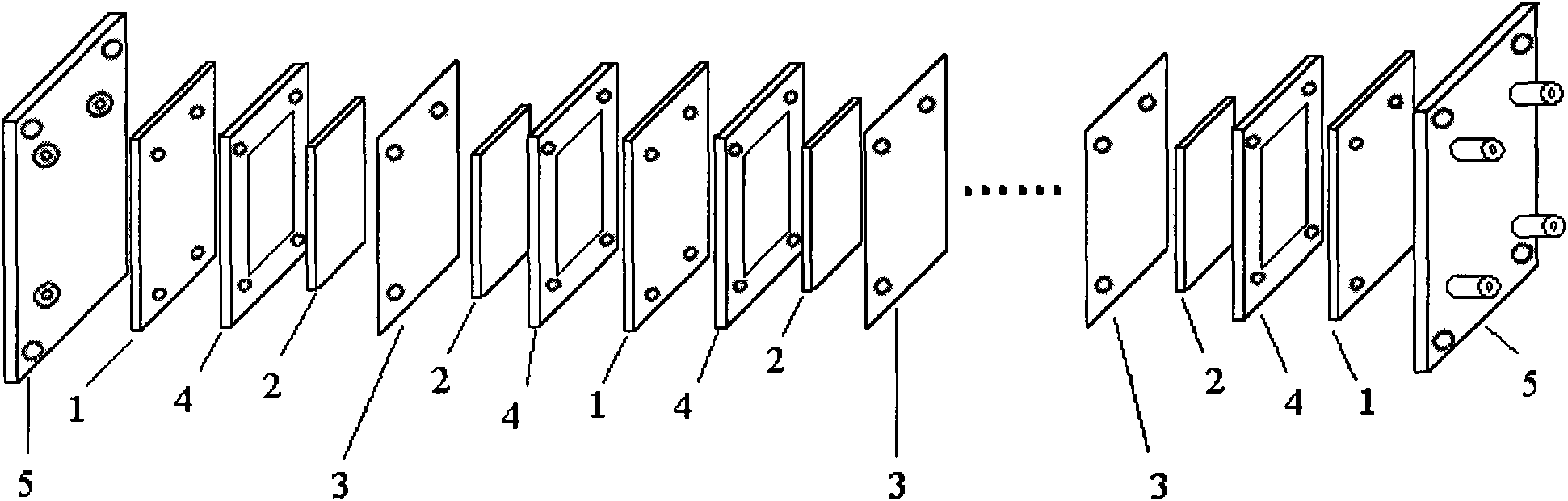

[0022] The liquid flow battery also provided by the present invention includes two end plates, a plurality of electrode plates, a positive electrode electrolyte, a negative electrode electrolyte and a plurality of diaphragms, and the plurality of electrode plates, the positive electrode electrolyte, the negative electrode electrolyte and a plurality of diaphragms are arranged Between the two end pl...

Embodiment 1

[0033] This example is used to illustrate the current collector of the flow battery provided by the present invention.

[0034] A conductive plastic plate of 200×200×2mm was polished by sandblasting, washed with dilute sulfuric acid (concentration 2mol / L) and deionized water in sequence, and then dried in a drying room for 0.5 hours. A 140×140×0.8mm flexible graphite plate (Yichang Xincheng Graphite Co., Ltd.) was polished by sandblasting, washed with dilute sulfuric acid (concentration 2mol / L) and deionized water in turn, and then placed in a drying room Dry in medium for 10min.

[0035] Wherein, the preparation method of conductive plastic plate is as follows:

[0036] Equipped with exhaust device, and the size is 34mm×34mm×40mm Figure 5 Shown flat-bottomed reactor (the inner space of reactor is made of base 51 and bell-shaped loam cake 52; On described bell jar-shaped loam cake 52, be equipped with exhaust port 53, through this exhaust port The operation of vacuumizing ...

Embodiment 2

[0039] This example is used to illustrate the current collector of the flow battery provided by the present invention.

[0040] Prepare the current collector of the flow battery in the same manner as in Example 1, except that the size of the flexible graphite plate is 130×130×0.3 mm, and the distance between the edge of the flexible graphite plate and the edge of the conductive plastic plate is 35 mm; and it is conductive The preparation method of the plastic plate is: mix polyethylene and graphite powder at a weight ratio of 1:1 at 40°C for 60 minutes; Plastic plates.

[0041] The current collector of the unipolar plate and the current collector of the bipolar plate are respectively denoted as A21 and A22.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com