Touch screen substrate, manufacturing method of touch screen substrate, touch panel and display device

A technology of touch panel and touch screen, which is applied in the direction of instruments, electrical digital data processing, and input/output process of data processing, etc. It can solve the problems of low cost, thick photoresist, and easy disconnection of electrode leads, etc., and achieves low cost, The production method is simple and the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

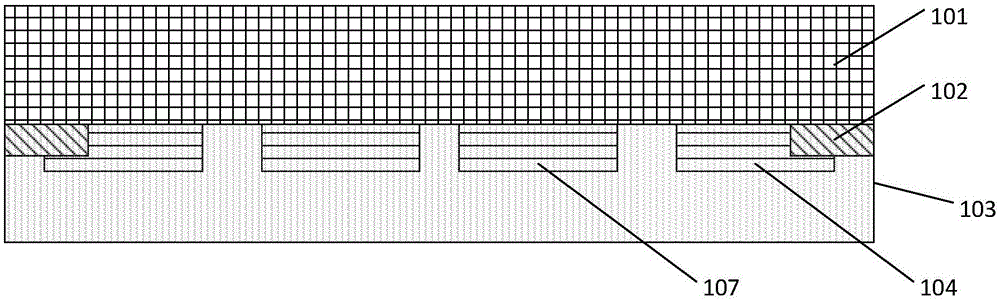

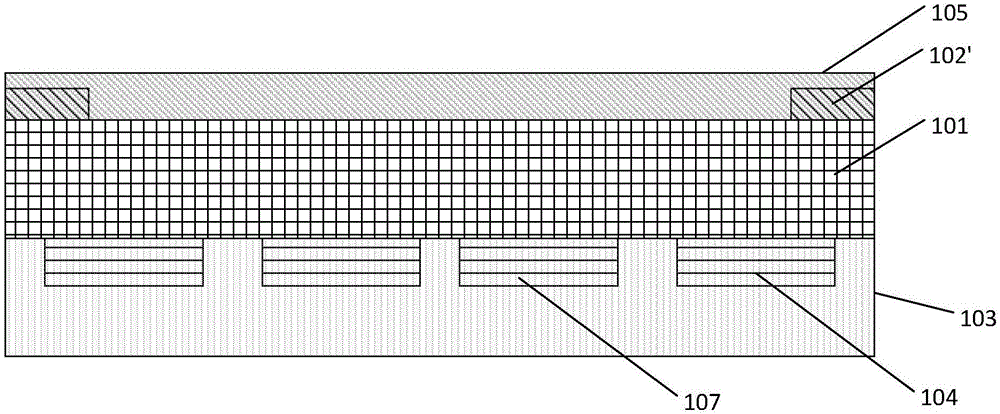

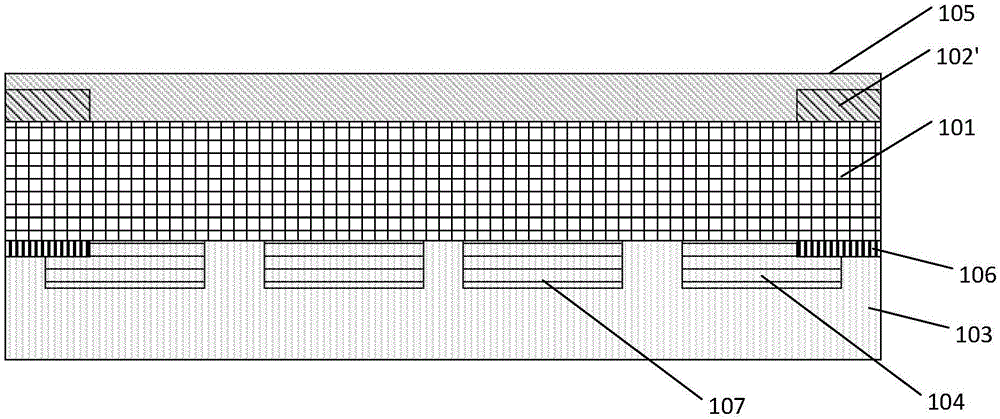

[0023] The specific implementation manners of the touch screen substrate and the manufacturing method thereof, the touch panel and the display device provided by the embodiments of the present application will be described in detail below with reference to the accompanying drawings.

[0024] The touch screen substrate mentioned in this application refers to a substrate that can realize the touch function including a base substrate, a touch electrode and an insulating layer. The display substrate with the above structure is integrated into the display panel with touch function, that is, the touch screen substrate can be an independent touch screen substrate, or a substrate integrated with other structures or functions such as a display substrate, which is not limited in this application.

[0025] The shape and size of each area in the drawings does not reflect the real proportion of the touch screen substrate, and the purpose is only to illustrate the content of the present appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com