Passive fluidic resistor suspension with equivalent mechanical structure

A liquid resistance suspension and mechanical structure technology, applied in the direction of mechanical equipment, power devices, jet propulsion devices, etc., can solve problems such as increased dynamic stiffness, reduce vibration transmission, increase drag coefficient, and improve vibration absorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

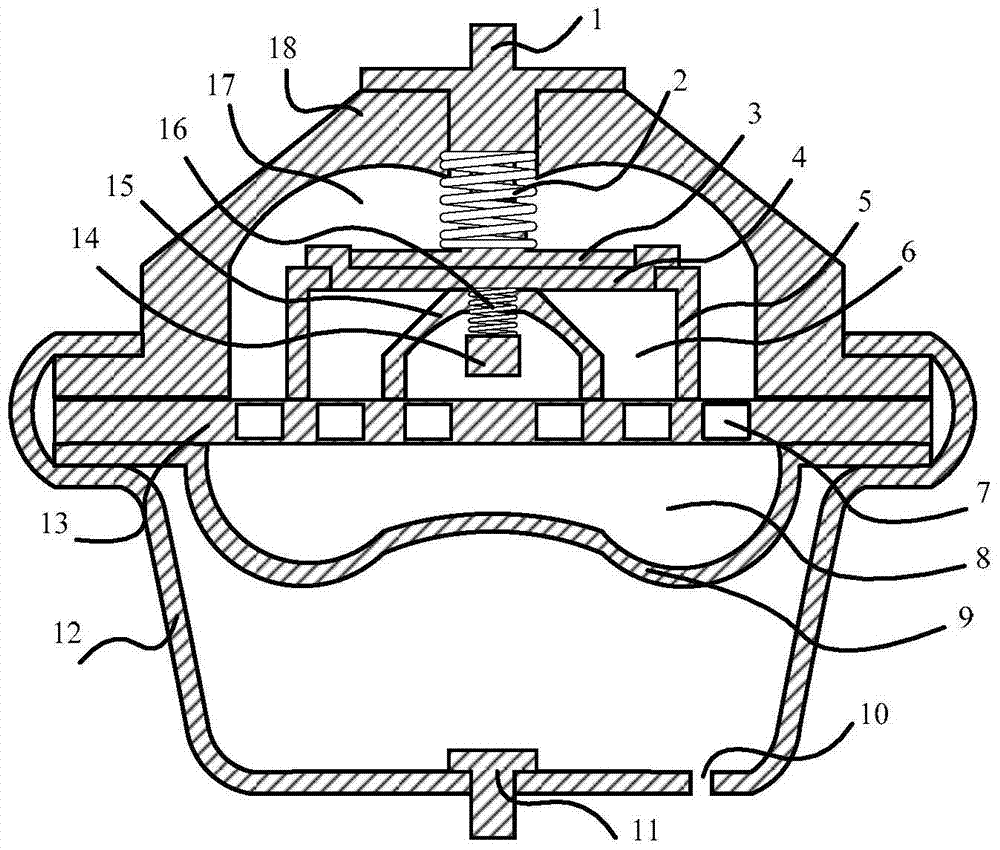

[0033]A passive hydraulic mount with an equivalent mechanical structure can be applied to the engine as a vibration damping device and connected between the engine and the car body, wherein the upper connecting bolts can be connected to the engine, and the lower mounting bolts can be connected to the body, so that the During the working process of the engine, the passive liquid resistance mount with an equivalent mechanical structure is connected between the engine and the frame of the vehicle as the vibration damping device of the vehicle, which can isolate the vibration of the engine, reduce the vibration transmitted to the body, and reduce the vibration of passengers. The resonant noise in the cabin improves the driving and riding comfort of the vehicle.

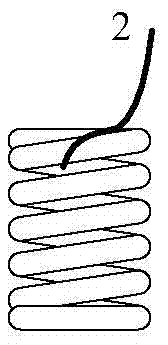

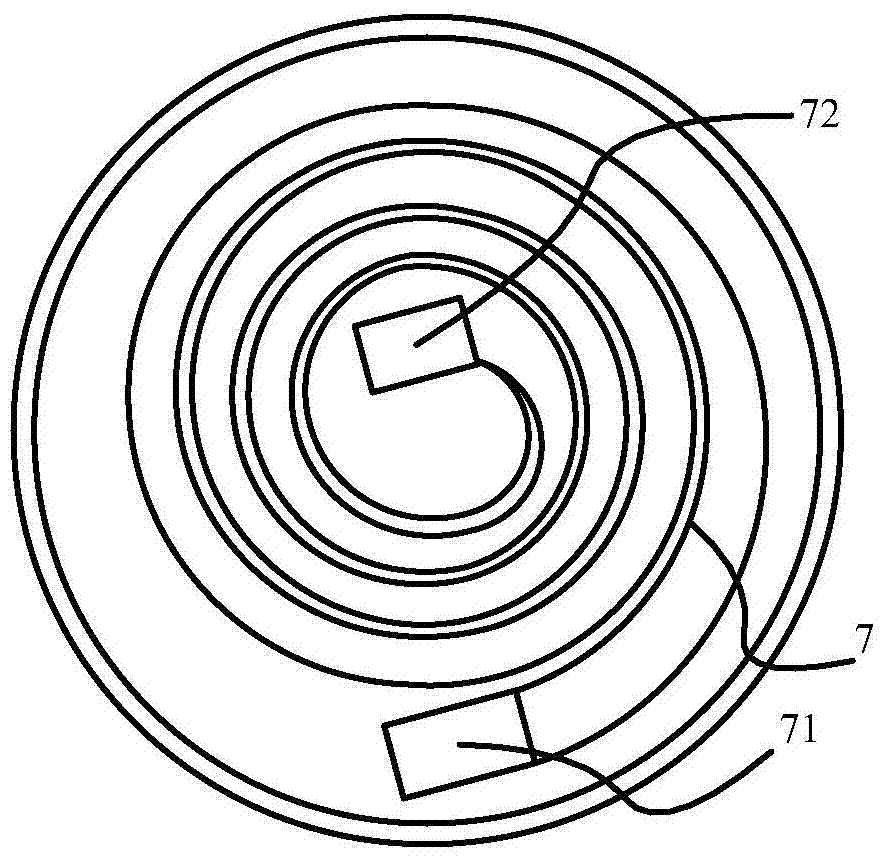

[0034] A passive liquid resistance mount with an equivalent mechanical structure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com