Creeping non-cured rubber asphalt waterproof roll material and preparation method thereof

A technology of asphalt waterproof membrane and non-curing rubber, which is applied in building insulation materials, building components, buildings, etc. It can solve the problems of poor weather resistance and poor bonding ability of concrete base surface, so as to improve creep performance and non-curing performance , Improve the effect of reaction binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

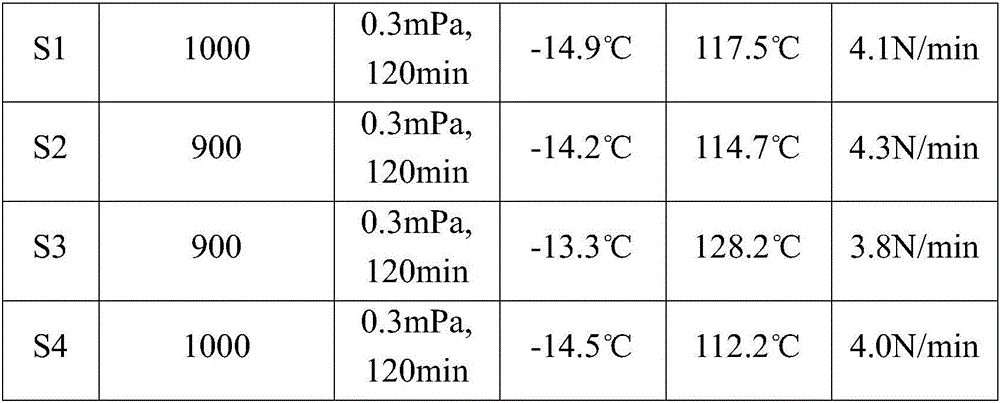

Embodiment 1

[0049] This embodiment provides a creep type non-cured asphalt waterproof membrane and a preparation method thereof, comprising the following steps:

[0050] Asphalt compound preparation: Add 50 parts by weight of base asphalt to a 1000L reactor, the base asphalt is selected from US150 high-quality oil asphalt, turn on the heating device, heat the base asphalt to 130-150°C, and add 20 parts by weight of styrene - Isoprene-styrene block copolymer, 3 parts by weight of α-pinene+β-pinene, 5 parts by weight of styrene-butadiene-styrene block copolymer, 2 parts by weight of ethylene - vinyl acetate copolymer and 2 parts by weight of styrene-butadiene rubber, the styrene-butadiene-styrene block copolymer adopts LG411 rubber modifier, heats up while stirring, and maintains the temperature after heating up to 185-195°C Stir for 1.5-2 hours until fully mixed, cool down to 165-175°C, add 5 parts by weight of grafted fumed silica, keep stirring for 1.0-1.5h until fully mixed, and natural...

Embodiment 2

[0054] This embodiment provides a creep type non-cured asphalt waterproof membrane and a preparation method thereof, comprising the following steps:

[0055] Asphalt compound preparation: add 60 parts by weight of base asphalt to a 1000L reactor, the base asphalt is selected from US150 high-quality oil asphalt, turn on the heating device, heat the base asphalt to 130-150°C, and add 15 parts by weight of styrene - Isoprene-styrene block copolymer, 4 parts by weight of α-pinene+β-pinene, 6 parts by weight of styrene-butadiene-styrene block copolymer, 3 parts by weight of ethylene - Vinyl acetate copolymer and 4 parts by weight of styrene-butadiene rubber, the styrene-butadiene-styrene block copolymer adopts LG411 rubber modifier, heats up while stirring, and maintains the temperature after heating up to 185-195°C No change, stir for 1.5-2 hours until fully mixed, cool down to 165-175°C, add 7 parts by weight of grafted fumed silica, keep stirring for 1.0-1.5h until fully mixed, ...

Embodiment 3

[0059] This embodiment provides a creep type non-cured asphalt waterproof membrane and a preparation method thereof, comprising the following steps:

[0060] Asphalt compound preparation: add 55 parts by weight of base asphalt to a 1000L reactor, the base asphalt is selected from US150 high-quality oil asphalt, turn on the heating device, heat the base asphalt to 130-150°C, and add 10 parts by weight of styrene - Isoprene-styrene block copolymer, 4 parts by weight of α-pinene+β-pinene, 5 parts by weight of styrene-butadiene-styrene block copolymer, 5 parts by weight of ethylene - vinyl acetate copolymer and 2 parts by weight of styrene-butadiene rubber, the styrene-butadiene-styrene block copolymer adopts LG411 rubber modifier, heats up while stirring, and maintains the temperature after heating up to 185-195°C Stir for 1.5-2 hours until fully mixed, cool down to 165-175°C, add 5 parts by weight of grafted fumed silica, keep stirring for 1.0-1.5h until fully mixed, and natural...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com